A Legacy of Problem Solving

The challenge of creating simple solutions to complex problems was a lifelong source of inspiration for J.M. Lapeyre

At the age of 16, while working one summer in his father’s shrimp cannery, young J.M. conceived the idea for a shrimp peeling machine after witnessing firsthand the inefficiencies and challenges of manual peeling.

The following summer, he built a working prototype and filed for his first patent. His innovative shrimp-peeling machine was soon patented, laying the foundation for the company he would eventually establish in 1949 – now known as Laitram Machinery. Today, Laitram Machinery stands as the world’s largest provider of shrimp processing technology. (Fun fact: “Laitram” is J.M.’s middle name spelled backward.)

The metal belts used to convey shrimp to the peeling machines were prone to rust and difficult to clean. To address this problem, J.M. designed and patented the first modular, all-plastic interlocking conveyor belt. This innovation led to the founding of Intralox in 1971, which has since grown into Laitram’s largest division.

Ten years later, in 1981, J.M. founded Lapeyre Stair to manufacture his patented, space-saving alternating tread stair.

A Stair is Born

It was after a fishing trip in 1978 that J.M. applied his pioneering mindset to a problem that had plagued ships, oil rigs, and factories for decades.

The observant J.M. noted the difficulty a workman had navigating steep stairs while carrying equipment on an offshore oil rig. Always intrigued by a challenge, he returned home, dusted his feet with talcum powder, and traced his natural gait as he descended his stairs – searching for a safer, more efficient stair design.

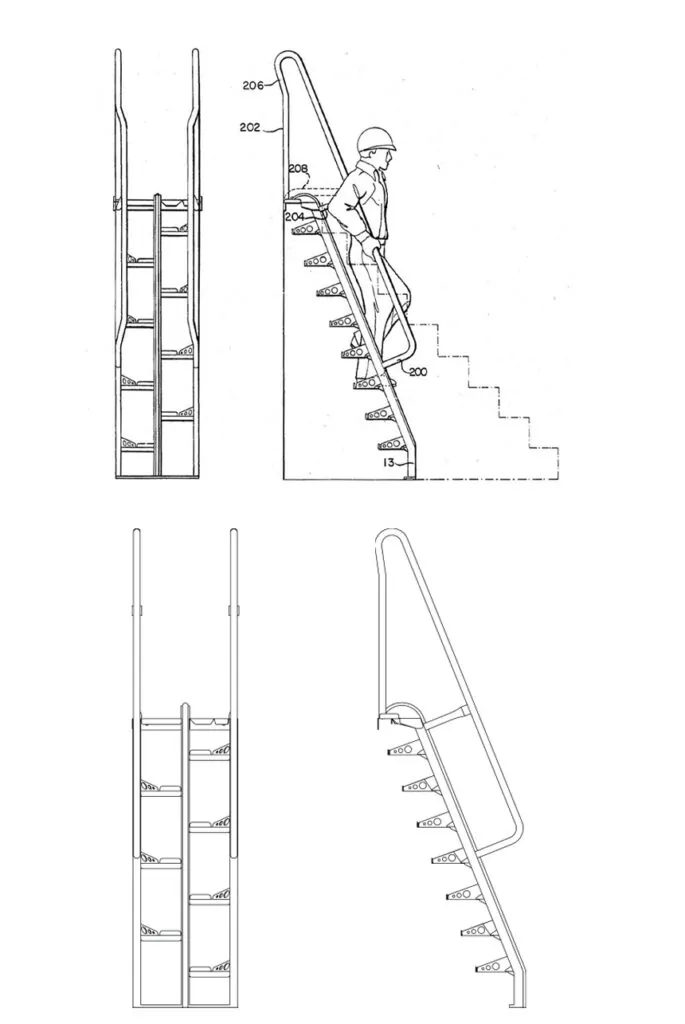

J.M. was able to prove his theory: the right foot naturally steps on every other tread on the right-hand side, while the left foot uses every other tread on the left. This observation led him to a breakthrough – by removing the unused half of each tread, he could create a safer, more compact stair design that provided a straight, direct path from one step to the next. A patent for his alternating tread design was awarded in 1980, and the following year, J.M. founded Lapeyre Stair to bring his innovative solution to market.

Our alternating tread stairs are now used across virtually every industry, enabling workers to safely and easily access mezzanines, crossovers, catwalks, and other tight spaces where conventional stairs won’t fit.

Continuously elevating standards

Lapeyre Stair operates a state-of-the-art production facility fully dedicated to stair manufacturing. Our current product line includes industrial access stairs, crossover bridges, roof access stairs, equipment platforms, and, of course, alternating tread stairs.

We also manufacture platforms, legs, and supports designed to easily integrate with our stair products into complete, custom systems. Every order we receive is custom-built to meet the project specifications and to comply with the applicable code requirements.

Our current manufacturing equipment line-up includes:

- Two high-definition plasma cutting tables for plate processing

- Three press brakes for tread processing

- CNC tube bender for handrails

We are committed to maintaining a state-of-the-art facility to ensure the quality of our products. All of our welders are certified to AWS D1.1 standard; we employ a full-time, certified weld inspector to conduct 100% weld inspections; and have a 24-hour resolution policy for addressing issues.