Automotive Solutions

Lapeyre Stair has been servicing America's automotive factories and supporting production facilities for more than 4 decades. If you're dealing with space constrained equipment access, fixed or folding ladder hazards, or just want to increase workplace efficiencies, we can help.

Proven Automotive Industry Success

Key Automotive Industry Facility Benefits

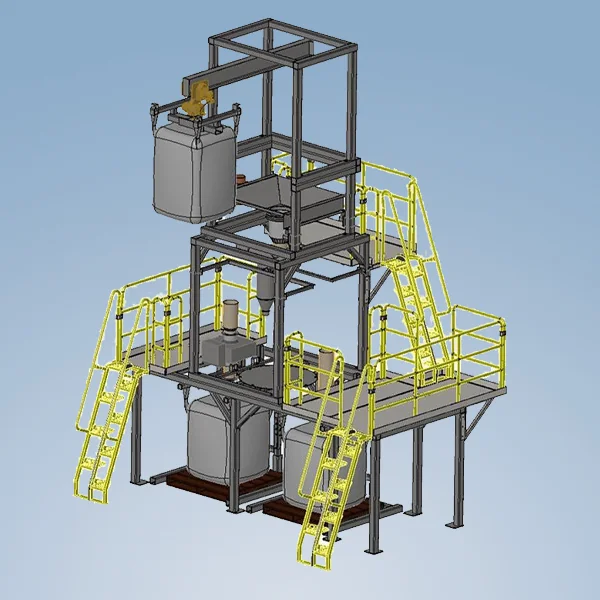

Our line of industrial stair systems provides safe, routine access to CNC Fabrication machines, tire conveyors, elevated conveyors, storage mezzanines, and equipment platforms.

Our products incorporate interchangeable components that are pre-engineered to comply with applicable OSHA and IBC standards.

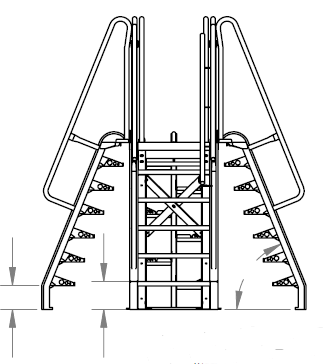

Our custom-designed and engineered crossover stair equipment access systems optimize workflow in and around your facility.

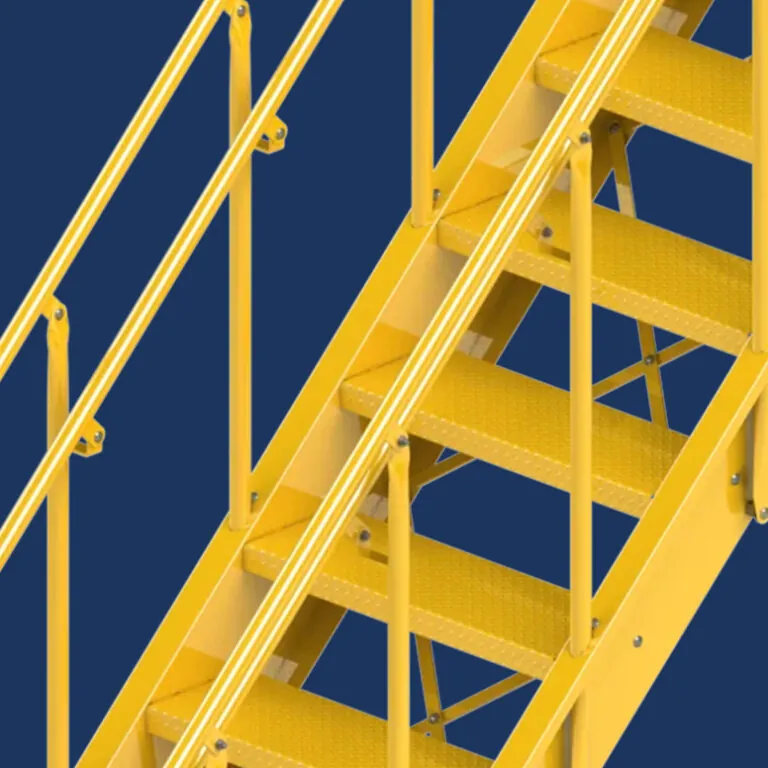

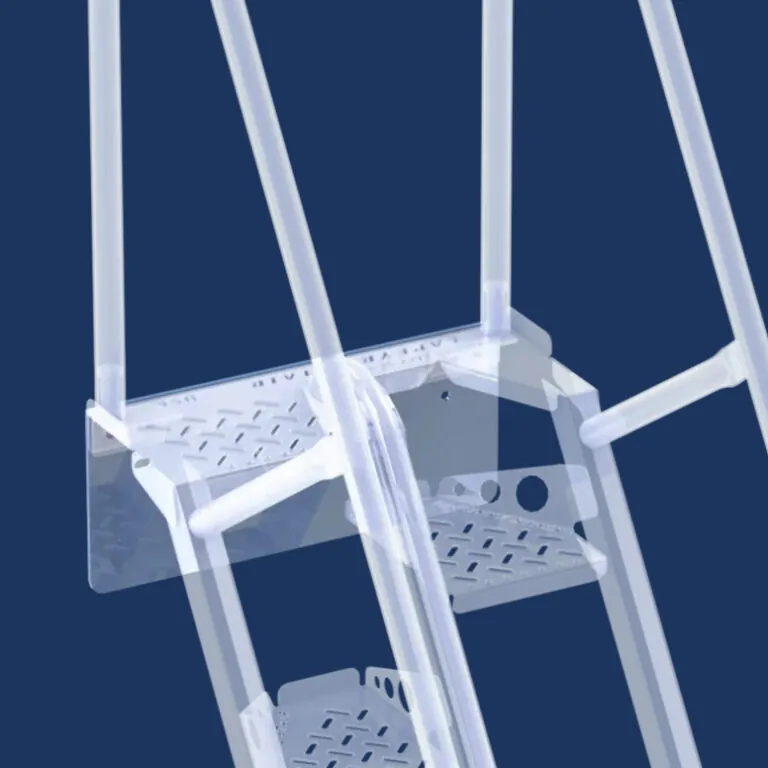

Replacing fixed vertical ladders with alternating tread stairs provides more useable tread depth, which means the entire foot is supported.

Our face-forward ascent and descent design encourages a neutral body posture, provides a stable tread surface, and eliminates the need for constant hand contact.

Photos of Automotive, Tire Production Installations

Automotive Technical Specs

| Equipment applications | CNC Fabrication, Rubber extruders, Tire building equipment, Internal mixers, Tire conveyors, Elevated conveyors, Storage mezzanines, Equipment platforms. |

| Possible issues | Space constrained equipment access, fixed or folding ladder hazards, workplace efficiencies. |

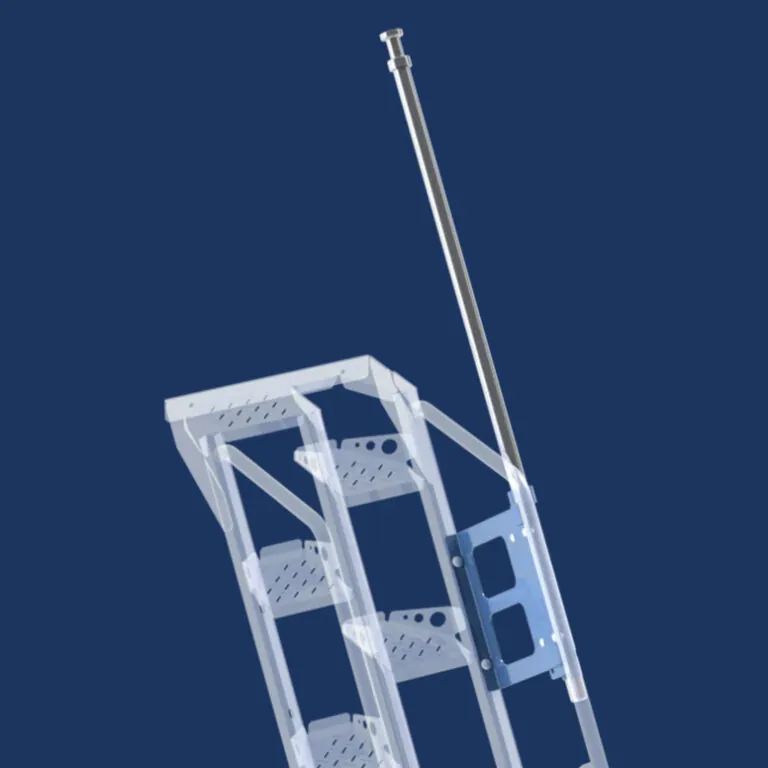

| Products | Alternating Tread Equipment Access Stairs Industrial Crossover Stair Systems, Alternating Tread Crossover Stair Systems Industrial Work Platforms Catwalks Mezzanines |

| Code Compliance | OSHA IBC Commercial IBC Industrial |

| Recommended Materials | Powder Coated Carbon Steel, Galvanized, Stainless Steel, Aluminum |

About Automotive and Tire Applications

Auto and the Alternating Tread Stair

When assessing opportunities for efficiencies and hazards, there are critical factors you should take into account before setting on a manufacturer. Alternating tread stairs help save 60% more space and eliminate the hazards of climbing ladders. 50% of ladder injuries are a result of climbing while carrying items up and down. Users can safely climb alternating tread stairs with tools or small objects while maintaining 3-point contact.

Space saving

Alternating tread stairs save space for your layout, enabling plant workers to safely carry tools while climbing which improves efficiency.

Eliminating fatigue, injuries

Fixed and temporary ladders are a primary source of fatigue and muscle injury for workers. Alternating tread stairs reduce worker recovery time by up to 54% compared to ships ladders and take 8% less energy to use

More About Lapeyre Stair?

When selecting your next set of stairs, here are few critical factors you should take into account before settling on a manufacturer.

Choose the right material

Galvanized? Aluminum? Powder-coated carbon steel? The choices may seem never ending, but rest assured there are specific applications for each material.

Understanding utility

Understanding the full range of utility your stair systems are expected to provide is worth a call. Our stair experts are standing by to jump on a call or video conference to help you assess the situation.

Measure twice, cut one

OSHA and IBC codes stipulate that certain elements and dimensions fall within specific variances. Lapeyre Stair provides local assistance to ensure that you’re ordering the right configuration and size.

Trust in your manufacturer

When you need to replace or replicate an existing design you need to know the company manufacturing them can deliver exactly what you need, repeatedly. Our precision guarantee and decades of experience mean you can count on it being right, whatever the build and whenever it’s needed.

Customer Care, Precision Guarentee

We are committed to maintaining a state-of-the-art facility to ensure the quality of our products. All of our welders are certified to AWS D1.1 standard; we employ a full-time, certified, weld inspector to conduct 100% weld inspections; and have a 24-hour resolution policy for addressing issues.

Automotive Industry Resources

Solutions for Any Size

Are you battling unimaginable layouts and obstacles? Put our team of engineers and designers to work solving your access headaches. We’ll work with you to design compliant solutions to your exact needs, down to a fraction of an inch.

Don't just take our word for it

Our standard product designs incorporate interchangeable components that are pre-engineered to comply with applicable codes and standards.

Testimonials

Case Studies