Design Resources

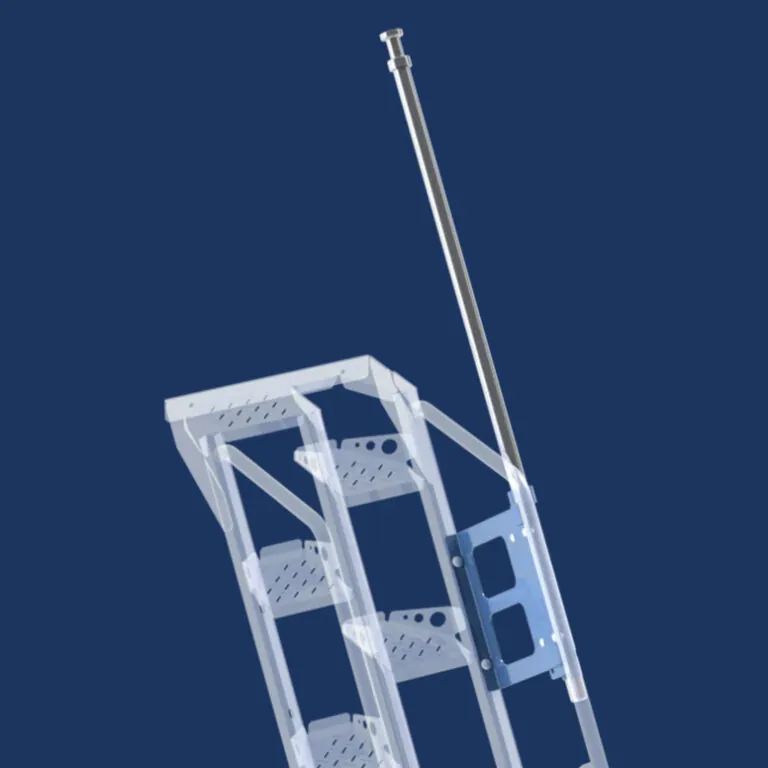

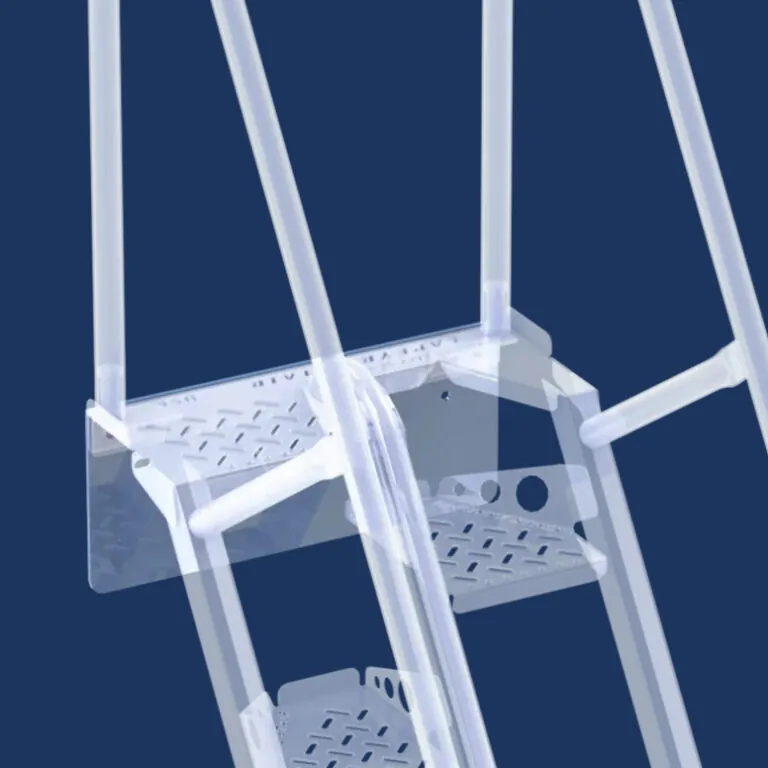

CAD Designs, 3D BIM Models, Specs

Online tools and downloads to quick start your next project.

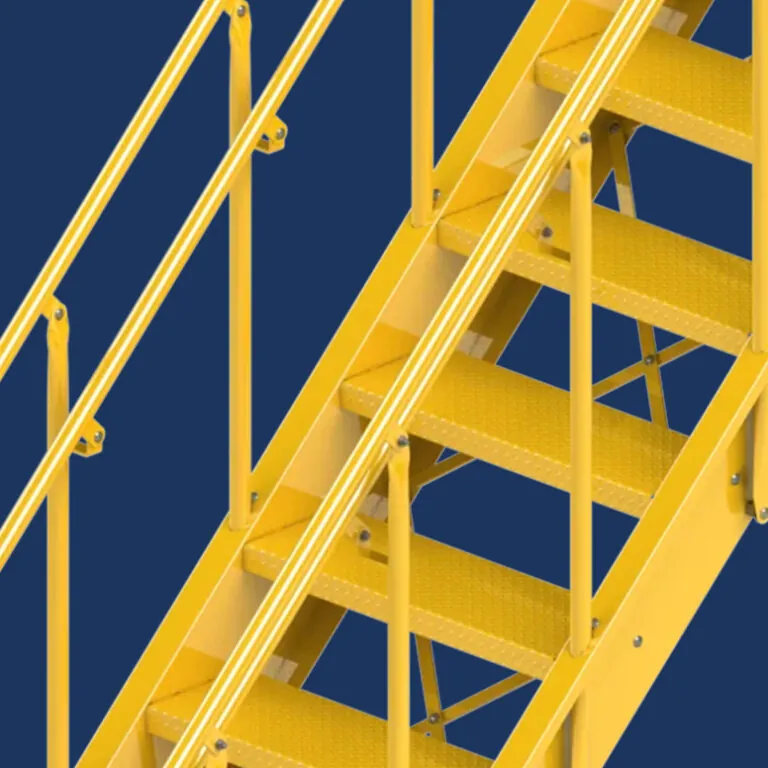

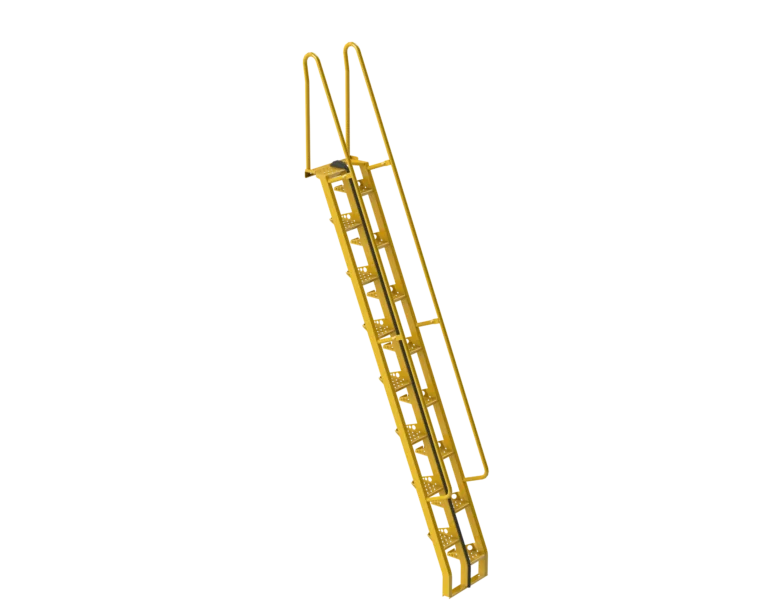

All Lapeyre Stair products are available in powder-coated or galvanized carbon steel. Alternating tread stair systems are also available in stainless steel or aluminum.

Technical Resources

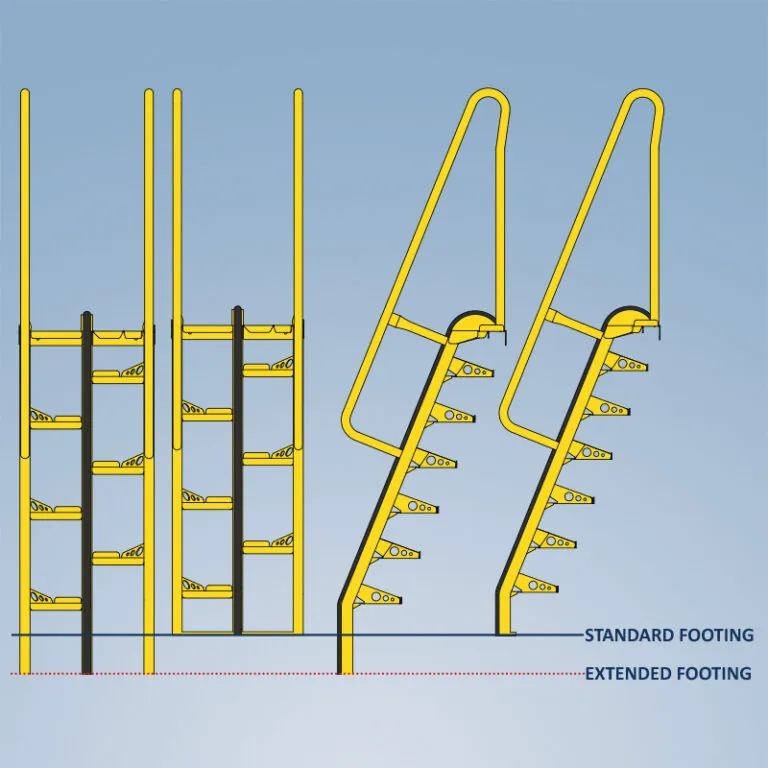

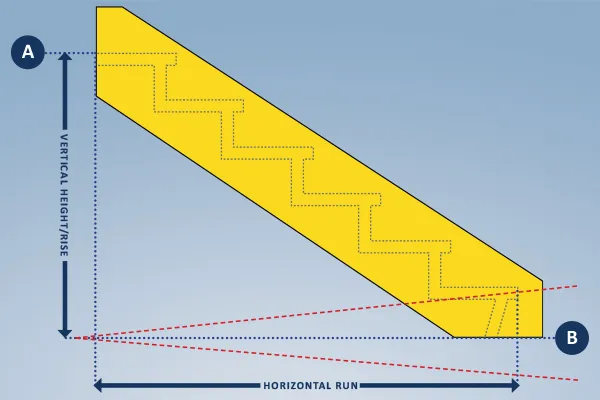

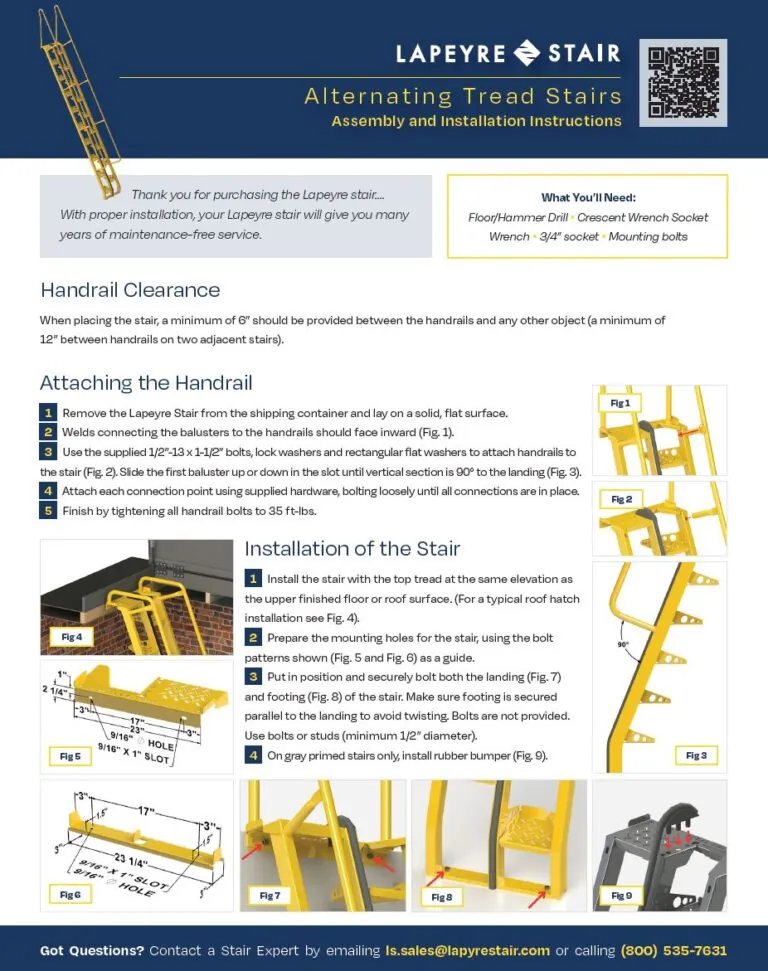

Dimensions and Measurements

Measuring guidelines, dimensions, and connection details.