OSHA Stair Code Compliance

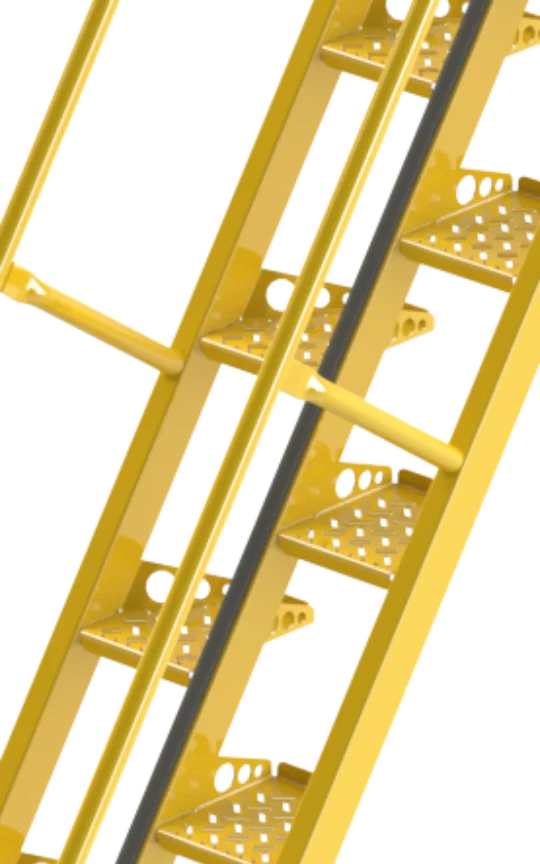

OSHA stairs requirements for alternating tread stairs

General OSHA stair requirements

5

Compliant fall protection

2

3

Uniform riser heights and tread depths

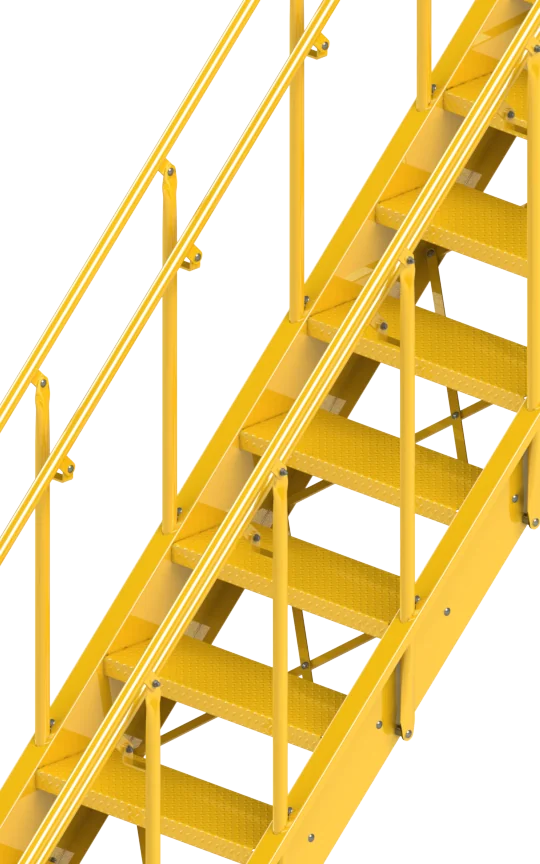

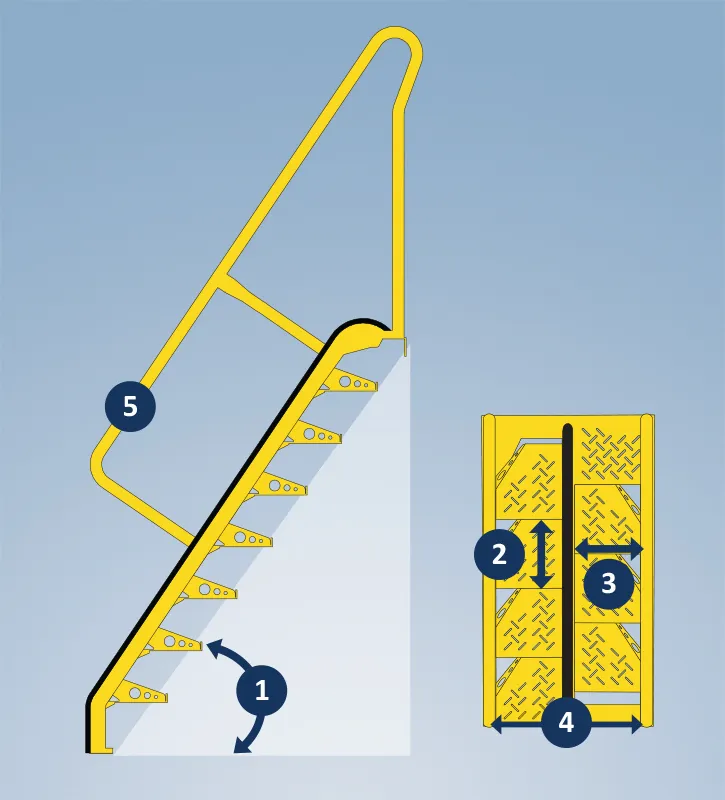

OSHA alternating tread stair requirements

1

Slope between 50° and 70° from the horizontal

2

Minimum tread depth of 8.5”

Open risers if tread depth is less than 9.5”

3

Minimum tread width of 7”

4

Distance between handrails of 17” to 24”

Duty to provide fall protection

5

Handrails on both sides

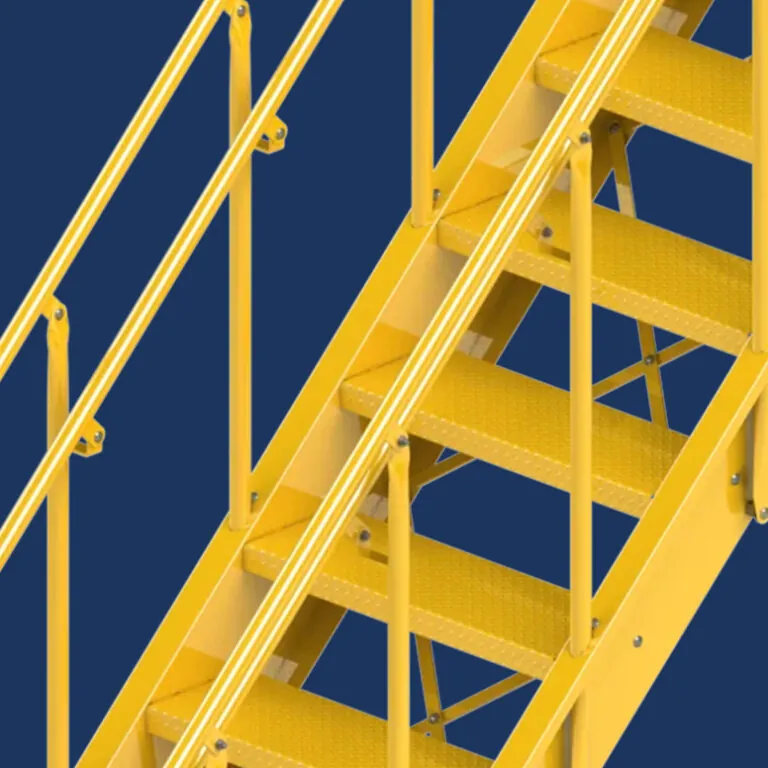

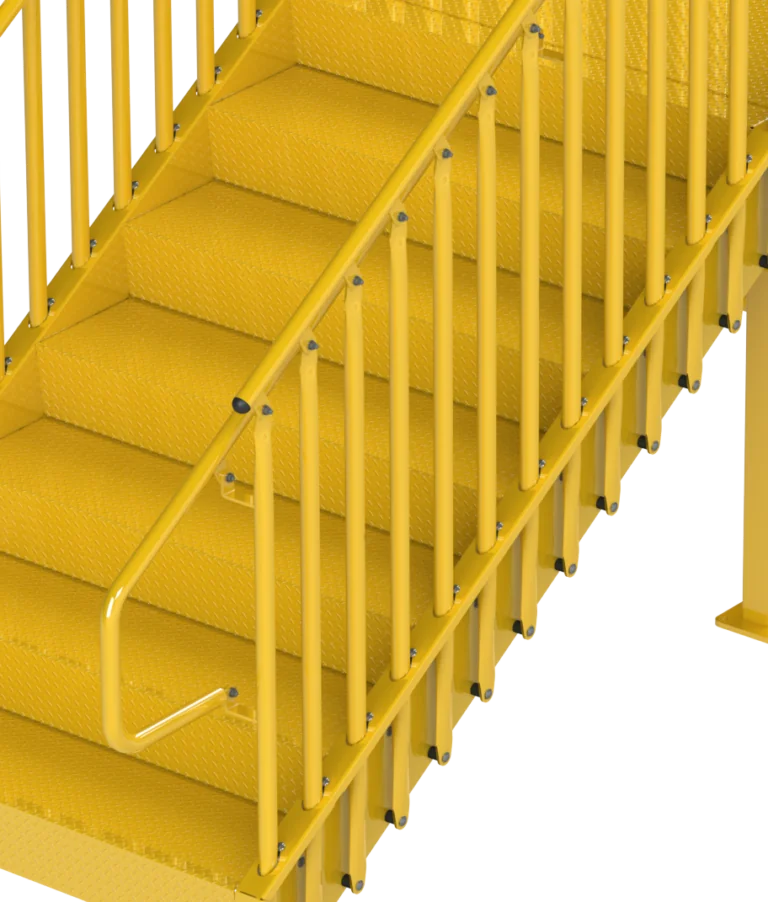

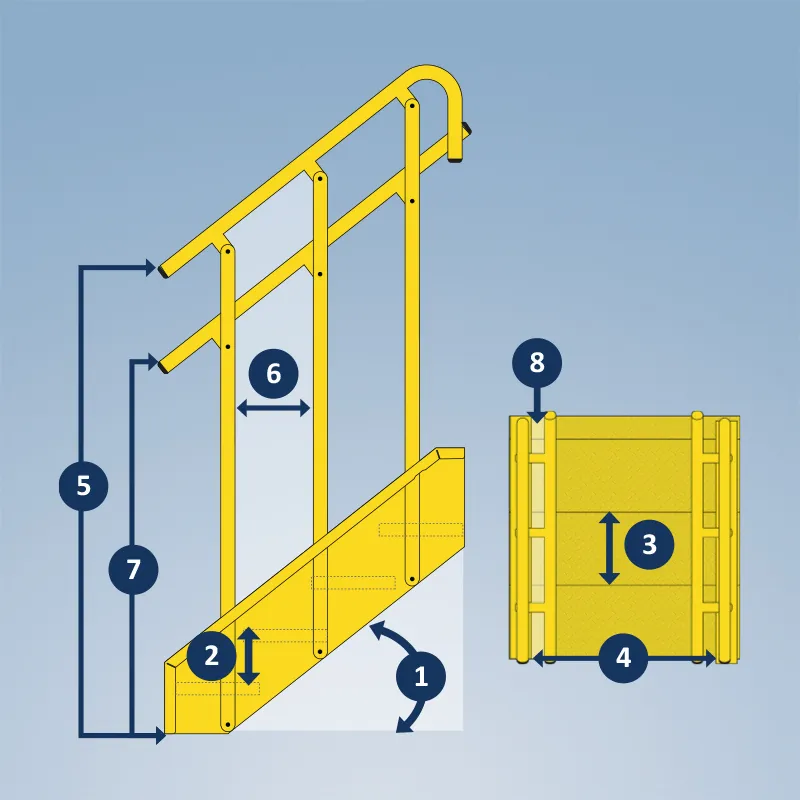

OSHA stair requirements for standard stairs

OSHA general stair requirements

Compliant fall protection (guardrail system)

2

3

Uniform riser heights and tread depths

OSHA requirements for standard stairs

1

Slope between 30° and 50° from the horizontal

2

Maximum riser height of 9.5"

3

Minimum tread depth of 9.5”

4

Minimum width of 22”

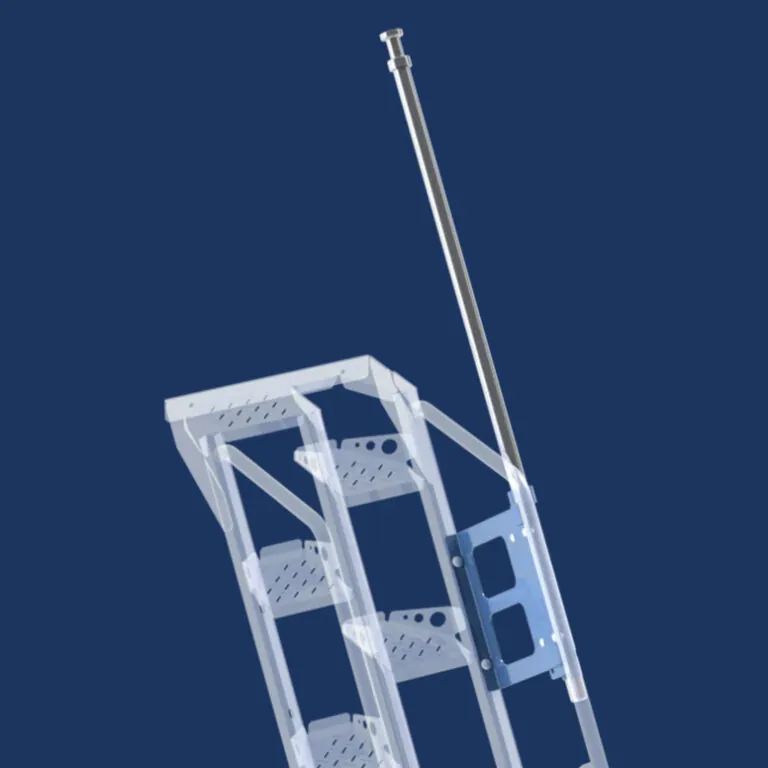

Duty to provide fall protection OSHA guardrail system requirements

OSHA handrail requirements

5

Top edge height of top rails is 42”

6

Maximum baluster spacing of 19”

7

Handrail height of 36”

8

Minimum finger clearance of 2.25”

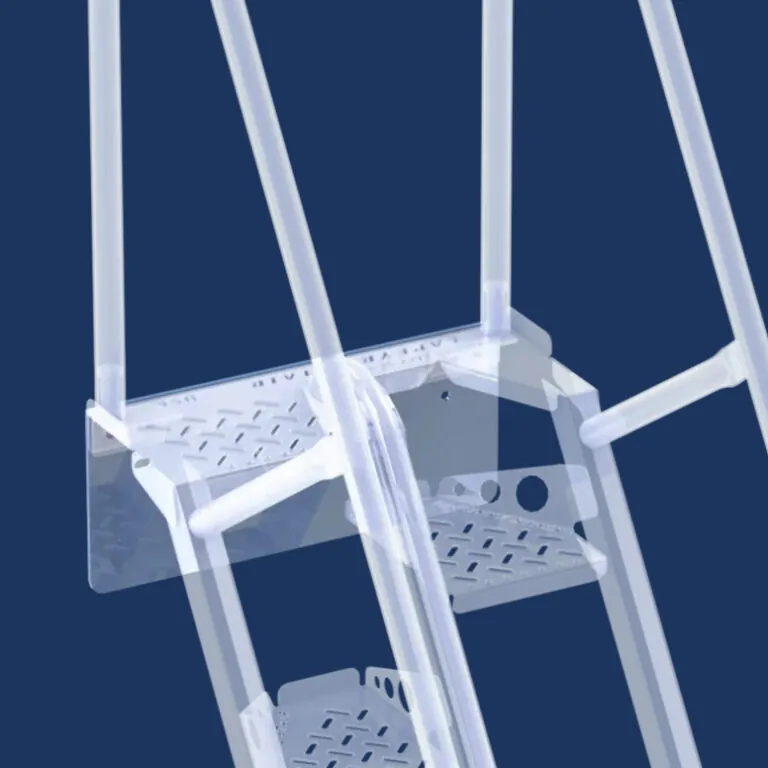

Additional OSHA stair requirements

Additional OSHA stair requirements

- Minimum vertical clearance above each tread of 6’8”

- Landings/platforms at least the width of the stair

- Landings/platforms at least 30” deep

- Door/gate swing does not reduce usable depth less than 22”

- Capable of supporting five normal anticipated load (not less than 1000#)

Additional OSHA guardrail requirements

- Capable of withstanding force of at least 200#

- Must be smooth-surfaced

- Top rail diameter of at least .25”

Additional OSHA handrail requirements

- Capable of withstanding force of at least 200#

- Must be smooth-surfaced

- Have shape and dimension to allow firm grasp

- Must be free of projection hazards

OSHA-compliant Stair Products and Applications

OSHA Requirements for Stairs

1910.25(a)

- Application. This section covers all stairways (including standard, spiral, ship, and alternating tread-type stairs), except for articulated stairs (stairs that change pitch due to change in height at the point of attachment) such as those serving floating roof tanks, stairs on scaffolds, stairs designed into machines or equipment, and stairs on self-propelled motorized equipment.

1910.25(b)

- General requirements. The employer must ensure:

1910.25(b)(1)

- Handrails, stair rail systems, and guardrail systems are provided in accordance with § 1910.28;

1910.25(b)(2)

- Vertical clearance above any stair tread to any overhead obstruction is at least 6 feet, 8 inches (203 cm), as measured from the leading edge of the tread. Spiral stairs must meet the vertical clearance requirements in paragraph (d)(3) of this section.

1910.25(b)(3)

- Stairs have uniform riser heights and tread depths between landings;

1910.25(b)(4)

- Stairway landings and platforms are at least the width of the stair and at least 30 inches (76 cm) in depth, as measured in the direction of travel;

1910.25(b)(5)

- When a door or a gate opens directly on a stairway, a platform is provided, and the swing of the door or gate does not reduce the platform’s effective usable depth to:

1910.25(b)(5)(i)

- Less than 20 inches (51 cm) for platforms installed before January 17, 2017; and

1910.25(b)(5)(ii)

- Less than 22 inches (56 cm) for platforms installed on or after January 17, 2017 (see Figure D-7 of this section);

1910.25(b)(6)

- Each stair can support at least five times the normal anticipated live load, but never less than a concentrated load of 1,000 pounds (454 kg) applied at any point;

1910.25(b)(7)

- Standard stairs are used to provide access from one walking-working surface to another when operations necessitate regular and routine travel between levels, including access to operating platforms for equipment. Winding stairways may be used on tanks and similar round structures when the diameter of the tank or structure is at least 5 feet (1.5 m).

1910.25(b)(8)

- Spiral, ship, or alternating tread-type stairs are used only when the employer can demonstrate that it is not feasible to provide standard stairs.

1910.25(b)(9)

- When paragraph (b)(8) of this section allows the use of spiral, ship, or alternating tread-type stairs, they are installed, used, and maintained in accordance with manufacturer’s instructions.

1910.25(c)

- Standard stairs. In addition to paragraph (b) of this section, the employer must ensure standard stairs:

1910.25(c)(1)

- Are installed at angles between 30 to 50 degrees from the horizontal;

1910.25(c)(2)

- Have a maximum riser height of 9.5 inches (24 cm);

1910.25(c)(3)

- Have a minimum tread depth of 9.5 inches (24 cm); and

1910.25(c)(4)

- Have a minimum width of 22 inches (56 cm) between vertical barriers (see Figure D-8 of this section).

1910.25(c)(5)

- Exception to paragraphs (c)(2) and (3) of this section. The requirements of paragraphs (c)(2) and (3) do not apply to standard stairs installed prior to January 17, 2017. OSHA will deem those stairs in compliance if they meet the dimension requirements specified in Table D-1 of this section or they use a combination that achieves the angle requirements of paragraph (c)(1) of this section.

1910.25(d)

- Spiral stairs. In addition to paragraph (b) of this section, the employer must ensure spiral stairs:

1910.25(d)(1)

- Have a minimum clear width of 26 inches (66 cm);

1910.25(d)(2)

- Have a maximum riser height of 9.5 inches (24 cm);

1910.25(d)(3)

- Have a minimum headroom above spiral stair treads of at least 6 feet, 6 inches (2 m), measured from the leading edge of the tread;

1910.25(d)(4)

- Have a minimum tread depth of 7.5 inches (19 cm), measured at a point 12 inches (30 cm) from the narrower edge;

1910.25(d)(5)

- Have a uniform tread size;

1910.25(e)

- Ship stairs. In addition to paragraph (b) of this section, the employer must ensure ship stairs (see Figure D-9 of this section):

1910.25(e)(1)

- Are installed at a slope of 50 to 70 degrees from the horizontal;

1910.25(e)(2)

- Have open risers with a vertical rise between tread surfaces of 6.5 to 12 inches (17 to 30 cm);

1910.25(e)(3)

- Have minimum tread depth of 4 inches (10 cm); and

1910.25(e)(4)

- Have a minimum tread width of 18 inches (46 cm).

1910.25(f)

- Alternating tread-type stairs. In addition to paragraph (b) of this section, the employer must ensure alternating tread-type stairs:

1910.25(f)(1)

- Have a series of treads installed at a slope of 50 to 70 degrees from the horizontal;

1910.25(f)(2)

- Have a distance between handrails of 17 to 24 inches (51 to 61 cm);

1910.25(f)(3)

- Have a minimum tread depth of 8.5 inches (22 cm); and

1910.25(f)(4)

- Have open risers if the tread depth is less than 9.5 inches (24 cm);

1910.25(f)(5)

- Have a minimum tread width of 7 inches (18 cm), measured at the leading edge of the tread (i.e., nosing).