Walking surfaces can be made from a variety of materials. Every day we walk on a combination of familiar materials including concrete, pavement, wood, tile and carpet. But have you ever noticed a metal or plastic surface with raised patterns and wondered what the purpose of it is? This article will explain diamond plate, how it is made and how it is commonly used.

What is diamond plate?

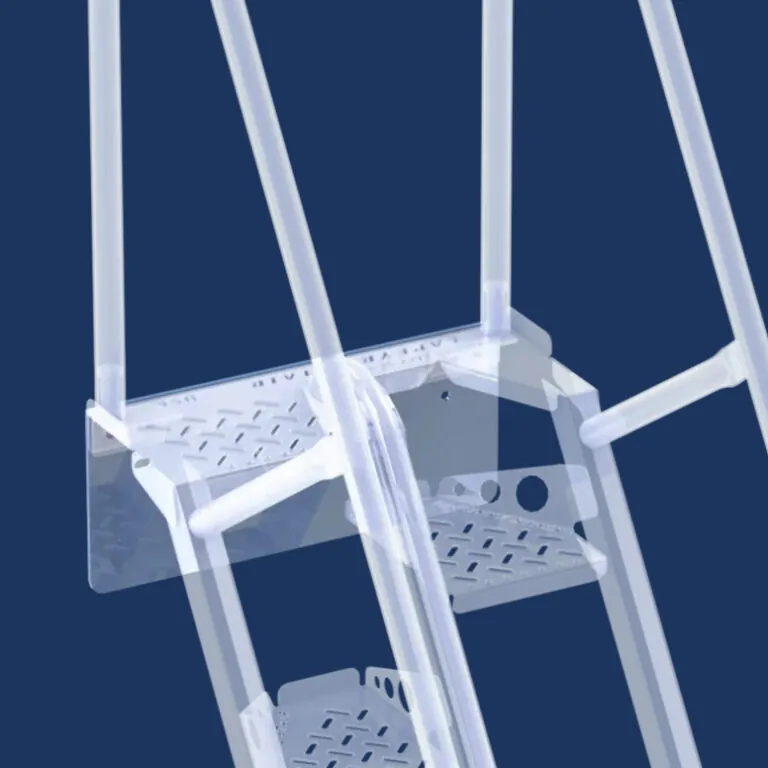

Diamond plate, also referred to as deck plate or floor plate, is a product that has a raised pattern or texture on one side with the reverse side being smooth. The diamond pattern itself can vary, as can the height of the raised area. Diamond plate is most commonly used on metal stairs to provide increased traction.

The raised bumps on the surface of the plate increase the friction between a person’s shoe and the surface of the plate reducing the chance of someone slipping on the walking surface. For this reason, diamond plate is a type of non-slip walking surface.

What is diamond plate made of?

Diamond plate is typically made of metal. The most popular types of metal used for diamond plate are aluminum, steel and stainless steel. In addition to diamond plated metal, plastic can also be used to create interlocking diamond plate sheets.

Diamond plate patterns are also used on rubber floor mats to help improve comfort and reduce fatigue in workspaces that require extended periods of standing.

Aluminum diamond plate

Aluminum diamond plate is corrosion resistant. Because of its ability to withstand the elements, aluminum deck plate is often found in outdoor settings such parking lots, loading docks and stairs. It is also used on boats, docks or other marine applications. Because diamond aluminum plate is easy to wash and keep clean, it can be found in kitchens, restrooms and walk-in refrigerators or freezers. Aluminum floor plate can also be used for a decorative purpose and is available in a variety of patterns and finishes.

Aluminum diamond plate is corrosion resistant. Because of its ability to withstand the elements, aluminum deck plate is often found in outdoor settings such parking lots, loading docks and stairs. It is also used on boats, docks or other marine applications. Because diamond aluminum plate is easy to wash and keep clean, it can be found in kitchens, restrooms and walk-in refrigerators or freezers. Aluminum floor plate can also be used for a decorative purpose and is available in a variety of patterns and finishes.

Steel diamond plate

Carbon steel is used make diamond plate for several of reasons. Its strength makes it good for use in structural applications. Diamond plated steel is often less expensive than other materials such as aluminum and stainless steel. Diamond pattern steel, which is durable and easy to clean, can be found in many commercial and industrial applications including stairs, ramps, trailer floors, vehicle running boards and truck beds.

Carbon steel is used make diamond plate for several of reasons. Its strength makes it good for use in structural applications. Diamond plated steel is often less expensive than other materials such as aluminum and stainless steel. Diamond pattern steel, which is durable and easy to clean, can be found in many commercial and industrial applications including stairs, ramps, trailer floors, vehicle running boards and truck beds.

Stainless steel diamond plate

Stainless steel is one of the more expensive materials to use for diamond plate. However, because it resistant to corrosion, it may be the best choice for environment that need to be sanitary or where harsh chemicals are used, such as in industrial settings. Like aluminum diamond plate, stainless steel diamond plate is also visually attractive due to its bright finish.

Plastic diamond plate

Diamond plate can also be made from plastic materials. Typically made in interlocking sheets which can be custom cut, plastic diamond plate is usually found in garages, offices, utility rooms and gyms. The sheets are available in different sizes, styles and finishes. Plastic diamond plate is waterproof and stain resistant. Plus, it can be painted to match the color of the environment and can also be used for wall panels.

How is metal diamond plate made?

Diamond metal plate can be made in one of two ways – by stamping or by being hot rolled. Both methods use a combination of heat and pressure.

With stamping, room temperature metal is passed between a series of large rollers. One roller is smooth and the other roller features the diamond pattern. The pressure of the metal passing between the rollers allows the diamond pattern to be transferred to one side of the metal. Stamping is commonly used to make aluminum diamond plates.

With hot rolling, the metal is flash heated above its recrystallization temperature using an electronic thermal machine before being passed through the rollers. The molten metal than cools into the diamond plate shape. Heating the metal helps prevent flaws from occurring and is often used to make steel diamond plates.

What is the point of diamond plate?

The point of diamond plate is to provide traction to reduce the risk of slipping. In industrial environments, non-skid diamond plate is used for stairs, catwalks, work platforms, walkways and ramps to improve safety. Aluminum treads are popular in outdoor environments. Diamond plate is often used on the interior of ambulances and on the footplates of firetrucks to make them slip resistant.

Diamond plate can also be used to prevent damage to surfaces from heavy traffic or abrasive chemicals. For examples, shipping docks often have durable diamond plate floors which can stand up to the heavy weight of forklifts transporting materials, but also offer increased traction to warehouse workers.

Finally, both metal and plastic diamond plate can be used for its aesthetic purposes. A variety of patterns, finishes and materials give diamond plate a wide variety of looks for any environment.

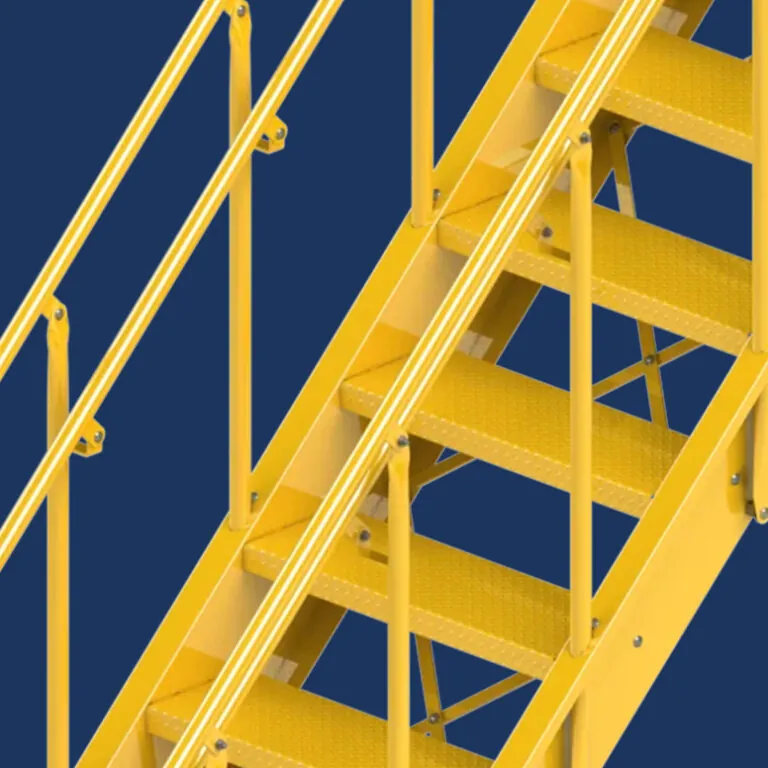

Diamond tread plate for stairs

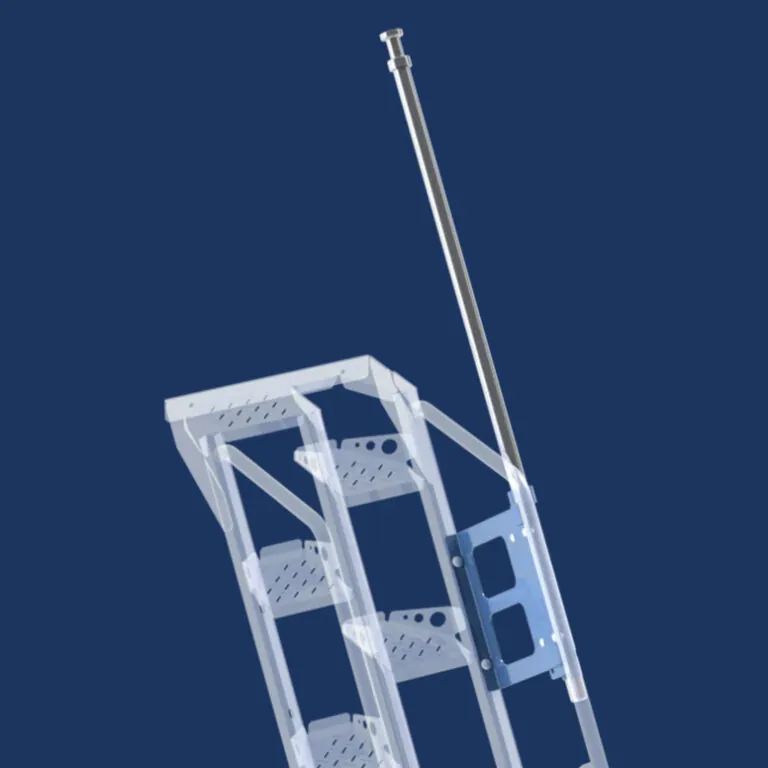

Diamond tread plates are often used for stairs in industrial areas. Both aluminum tread plate and diamond steel plate can be used to increase traction on stair treads, making the staircase safer to climb. Diamond plate is also often used for outdoor metal stairs in commercial buildings with high traffic.

Diamond tread plates are often used for stairs in industrial areas. Both aluminum tread plate and diamond steel plate can be used to increase traction on stair treads, making the staircase safer to climb. Diamond plate is also often used for outdoor metal stairs in commercial buildings with high traffic.

What is the difference between diamond plate, checker plate & tread plate?

Diamond plate, checker plate and tread plate are all different names used for the same material featuring a raised surface on one side. The terms are frequently used interchangeably and often include the type of material used. Examples include phrases such as diamond pattern metal, checker plate steel, aluminum checker plate and diamond tread aluminum.

Key takeaways on diamond plating

Diamond plating is a common way to add traction and slip-protection to walking surfaces. Diamond plate can be made of aluminum, steel or plastic. It comes in a variety of patterns and finishes and has a wide range of applications. Now, the next time you see a surface with raised diamond or other patterns, you will know exactly what it is and that it is meant to help you get to your destination safely.

Where to buy diamond plate aluminum

Diamond plate aluminum can be bought from specialty metal suppliers such as Specialty Metals Supply. For stairs and platforms made with aluminum diamond plate, Lapeyre Stair manufacturers industrial stairs, crossover stairs, and other work platforms with aluminum diamond plate.

FAQs

What material is diamond plate?

Diamond plate, also referred to as deck plate or floor plate, is a product used for floor surfaces that has a raised pattern or texture on one side. The raised bumps create friction to reduce the chance of slipping. It can be made from a variety of metals or plastic.

When was diamond plate invented?

It is unknown exactly when diamond plate was invented or who invented it. Diamond plate was likely invented by the steelmaking industry in the early-to-mid 20th century as a hot-rolled plate product to be used as a non-slip floor surface in industry.

Is diamond plate strong?

Diamond plate made of steel or aluminum is strong enough for floor surfaces in most applications. The strength of diamond plate depends on the gauge of the plate. Diamond plate used for catwalks or stairs usually has a thickness between 11 gauge (.1196 inches) and 3/8 (.375) inches.