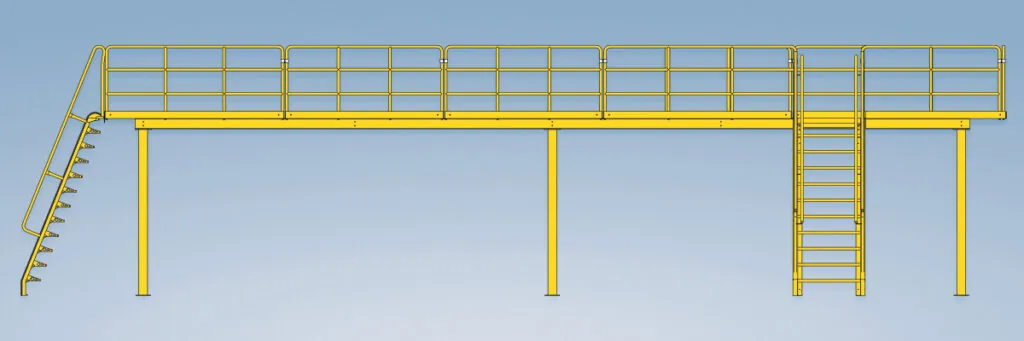

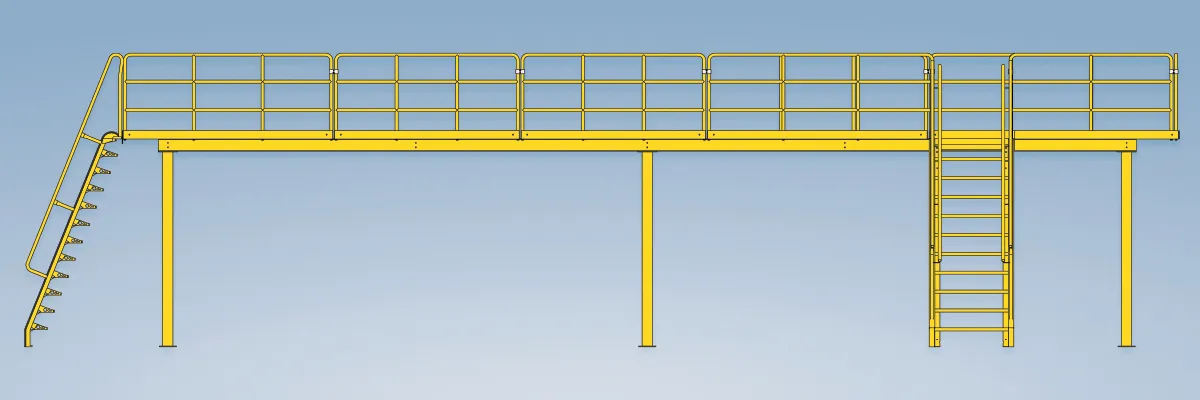

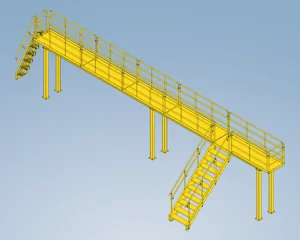

An industrial catwalk is a narrow, elevated walkway or elongated platform used in industrial applications to provide safe access to elevated work areas. Catwalks, or runways, provide a means of access to equipment, maintenance areas and other hard-to-reach areas within a facility. The OSHA catwalk requirements for general industry address many design variables to ensure that these systems are safe for employees. OSHA sets the catwalk standards for the minimum width dimensions, minimum load requirements, fall protection requirements, and the catwalk opening requirements. Understanding these requirements can help ensure a safe work environment for equipment operators and maintenance personnel working on catwalks.

Why are the OSHA catwalk standards in place?

The OSHA catwalk standards are in place to ensure safe and healthful working and walking conditions for men and women using catwalks in the workplace. OSHA 29 CFR 1910 Subpart D – Walking-Working Surfaces addresses the requirements for catwalk dimensions, catwalk minimum load requirements, and catwalk fall protection.

OSHA catwalk requirements

The OSHA catwalk requirements are found in OSHA Section 1910 Subpart D – Walking-Working Surfaces. A catwalk, or runway, is an elevated walking-working surface, a foot walk along shafting, or an elevated walkway between buildings. A catwalk is also a type of industrial work platform. Employers must ensure catwalks are maintained in safe, hazard-free conditions.

OSHA catwalk system

OSHA Section 1910.22 outlines the general conditions for walking-working surfaces, which includes catwalks. Employers must ensure that walking-surfaces are free of fall hazards, slip resistant, and structurally sound. Here are the key criteria for elevated working conditions with which employers must comply:

OSHA Section 1910.22 outlines the general conditions for walking-working surfaces, which includes catwalks. Employers must ensure that walking-surfaces are free of fall hazards, slip resistant, and structurally sound. Here are the key criteria for elevated working conditions with which employers must comply:

1910.22(a)(1) All places of employment, passageways, storerooms, service rooms, and walking-working surfaces are kept in a clean, orderly, and sanitary condition.

1910.22(a)(3) Walking-working surfaces are maintained free of hazards such as sharp or protruding objects, loose boards, corrosion, leaks, spills, snow, and ice.

1910.22(b) The employer must ensure that each walking-working surface can support the maximum intended load for that surface.

1910.22(c) The employer must provide, and ensure each employee uses, a safe means of access and egress to and from walking-working surfaces.

1910.22(d)(1) Walking-working surfaces are inspected, regularly and as necessary, and maintained in a safe condition

1910.22(d)(2) Hazardous conditions on walking-working surfaces are corrected or repaired before an employee uses the walking-working surface again. If the correction or repair cannot be made immediately, the hazard must be guarded to prevent employees from using the walking-working surface until the hazard is corrected or repaired; and

1910.22(d)(3) When any correction or repair involves the structural integrity of the walking-working surface, a qualified person performs or supervises the correction or repair.

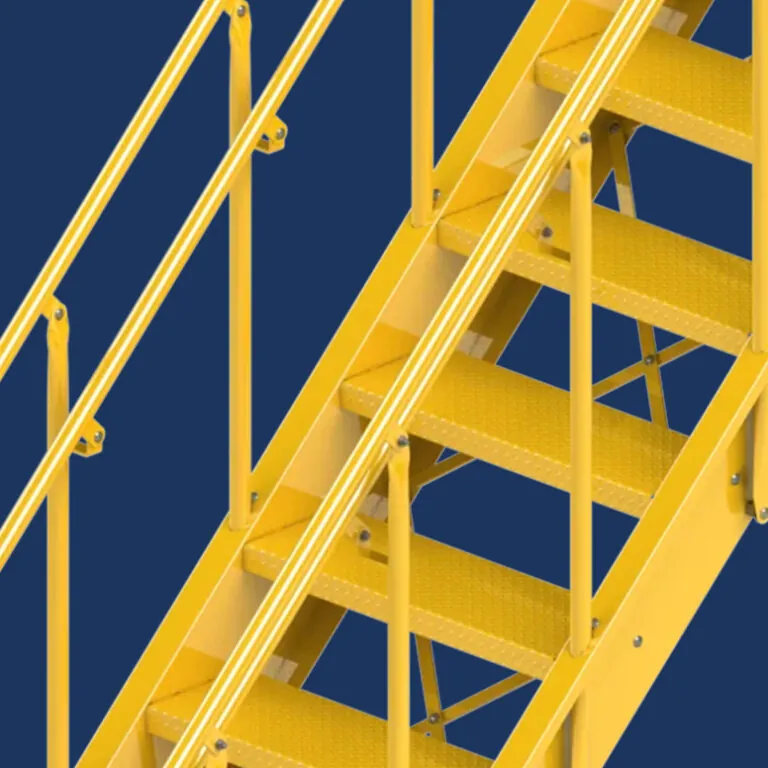

OSHA catwalk stair requirements

Elevated catwalks should be provided access by a stairway. The maximum riser height for an OSHA standard stair is 9.5 inches and the minimum stair tread is 9.5 inches. Any change in elevation in walking surfaces greater than 9.5 inches should be serviced by stairway.

Different types of stairs may be used to access catwalks. These types include standard stairs, alternating tread stairs, ship stairs, or spiral stairs.

Standard stairs should be used to provide access from one walking-working surface to another when operations necessitate regular and routine travel between levels, including access to operating platforms for equipment.

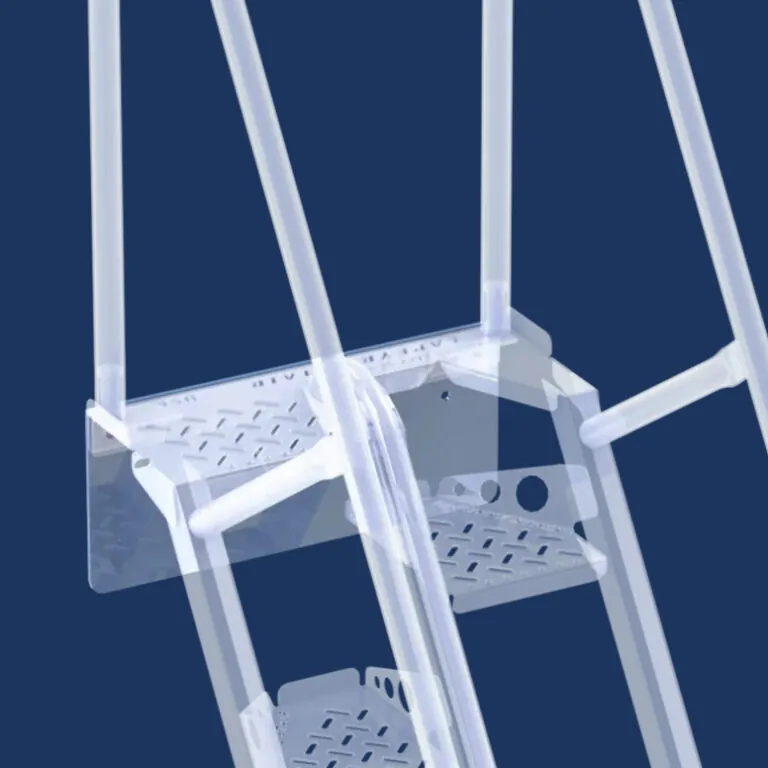

OSHA Section 1910.25(b)(8) states that spiral, ship, or alternating tread-type stairs are used only when the employer can demonstrate that it is not feasible to provide standard stairs. Catwalks in tight spaces may be accessed by these types of non-standard stairs. Fixed ladders should be avoided for accessing catwalks.

For applications with limited space, the alternating tread stair is the safest, and most efficient option to access catwalks. Users can walk up and down the stair face-forward while carrying tools or other objects to perform maintenance work. You can see the difference between the alternating tread stair and a steep stair in this video.

Each stair must also be provided with a railing system. Section 1910.28(b)(11)(ii) states that a flight of stairs having at least 3 treads and at least 4 risers must be equipped with stair rail system.

OSHA catwalk width requirements

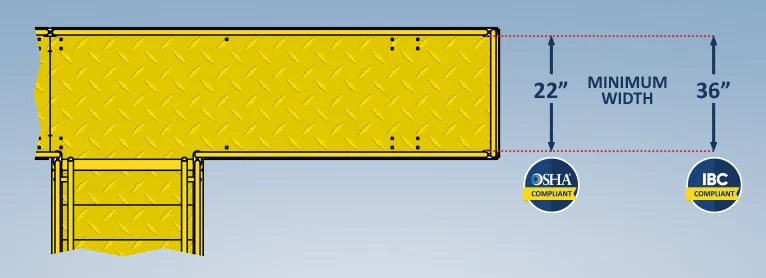

The OSHA catwalk width requirements are found in section 1910.28(b)(5)(ii)(A). Under this provision, a catwalk or runway must be at least 18 inches wide.

If a stairway accesses the catwalk, the width requirements depend on the width of the stairway that serves it. An OSHA catwalk serviced by a stairway is a type of stair landing. Under OSHA Section 1910.25(b)(4) the stairway landing must be at least the width of the stairway, which has a minimum width of 22″. In that case, OSHA catwalks served by a stairway must have a minimum width of 22.”

Catwalks accessed by IBC stairs must also be at least as wide as the IBC stair, which has a minimum width of 36.” In that case, the catwalk should be minimum of 36″ wide. Certain larger catwalks may actually be categorized as mezzanine structures and would need to comply with the IBC mezzanine egress requirements.

OSHA catwalk load requirements

The OSHA catwalk load requirements are addressed in Section 1910.21 and 1910.22 – General requirements for Walking-working surfaces.

The maximum intended load means the total load (weight and force) of all employees, equipment, vehicles, tools, materials, and other loads the employer reasonably anticipates to be applied to a walking-working surface at any one time.

Under section 1910.22(b) Loads, the employer must ensure that each walking-working surface can support the maximum intended load for that surface.

For hole covers, section 1910.29(e) specifies that the employer must ensure each cover for a hole in a walking-working surface is capable of supporting without failure, at least twice the maximum intended load that may be imposed on the cover at any one time.

For guardrail systems around a catwalk, section 1910.29(b)(3) requires that guardrail systems are capable of withstanding, without failure, a force of at least 200 pounds (890 N) applied in a downward or outward direction within 2 inches (5 cm) of the top edge, at any point along the top rail. And section 1910.29(b)(4) requires that when the 200-pound (890-N) test load is applied in a downward direction, the top rail of the guardrail system must not deflect to a height of less than 39 inches (99 cm) above the walking-working surface.

OSHA catwalk handrail requirements

The OSHA catwalk handrail requirements are found in OSHA sections 1910.28 and 1910.29 – Fall protection systems and falling object protection-criteria and practices. A catwalk handrail or guardrail system is required for any catwalks higher than 4′ above a lower level.

OSHA requires that employers provide fall protection for employees on any walking-working surface with an unprotected side or edge that is 4 feet or more above a lower level. The fall protection must be either a guardrail system, safety net system, or personal fall protection system.

In some cases, employers may mark part of the walking surface as a designated area delineated by a warning line in which employees may perform work without additional fall protection. These areas should only be designated for work that is both infrequent and temporary.

OSHA section 1910.28(b)(5)(i) requires that the employer must ensure each employee on a runway or similar walkway is protected from falling 4 feet or more to a lower level by a guardrail system.

When the employer can demonstrate that it is not feasible to have guardrails on both sides of a runway used exclusively for a special purpose, the employer may omit the guardrail on one side of the runway, provided the employer ensures the runway is at least 18 inches wide and each employee is provided with and uses a personal fall arrest system or travel restraint system.

Employers must also ensure that each employee less than 4 feet above dangerous equipment is protected from falling into or onto the dangerous equipment by a guardrail system or a travel restraint system, unless the equipment is covered or guarded to eliminate the hazard.

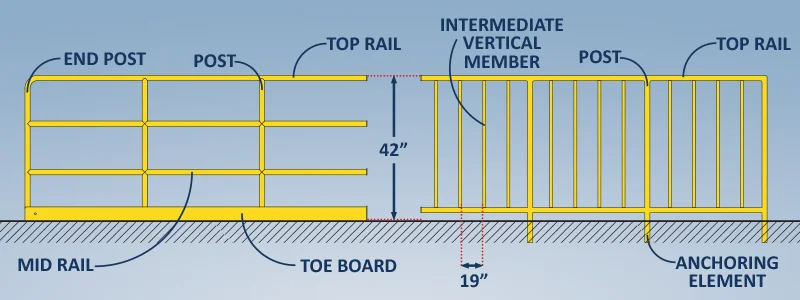

Typically open sides of catwalks are protected by guardrail systems. Below are the guardrail system design requirements for the different types of handrails that can be used as guardrail systems.

1910.29(b)(1) The top edge height of top rails, or equivalent guardrail system members, are 42 inches plus or minus 3 inches above the walking-working surface. The top edge height may exceed 45 inches provided the guardrail system meets all other criteria of paragraph (b) of this section.

1910.29(b)(2) Mid-rails, screens, mesh, intermediate vertical members, solid panels, or equivalent intermediate members are installed between the walking-working surface and the top edge of the guardrail system as follows when there is not a wall or parapet that is at least 21 inches.

1910.29(b)(2)(i) Mid-rails are installed at a height midway between the top edge of the guardrail system and the walking-working surface

1910.29(b)(2)(ii) Screens and mesh extend from the walking-working surface to the top rail and along the entire opening between top rail supports

1910.29(b)(2)(iii) Intermediate vertical members (such as balusters) are installed no more than 19 inches apart

1910.29(b)(2)(iv) Other equivalent intermediate members (such as additional mid-rails and architectural panels) are installed so that the openings are not more than 19 inches wide.

1910.29(b)(3) Guardrail systems are capable of withstanding, without failure, a force of at least 200 pounds applied in a downward or outward direction within 2 inches of the top edge, at any point along the top rail.

1910.29(b)(4) When the 200-pound (890-N) test load is applied in a downward direction, the top rail of the guardrail system must not deflect to a height of less than 39 inches above the walking-working surface.

1910.29(b)(5) Mid-rails, screens, mesh, intermediate vertical members, solid panels, and other equivalent intermediate members are capable of withstanding, without failure, a force of at least 150 pounds (667 N) applied in any downward or outward direction at any point along the intermediate member.

1910.29(b)(6) Guardrail systems are smooth-surfaced to protect employees from injury, such as punctures or lacerations, and to prevent catching or snagging of clothing.

1910.29(b)(7) The ends of top rails and mid-rails do not overhang the terminal posts, except where the overhang does not pose a projection hazard for employees.

1910.29(b)(8) Steel banding and plastic banding are not used for top rails or mid-rails.

1910.29(b)(9) Top rails and mid-rails are at least 0.25-inches (0.6 cm) in diameter or in thickness.

1910.29(k)(2)(ii) All openings in guardrail systems are small enough to prevent objects from falling through the opening.

OSHA Catwalk toe board requirements

OSHA also requires that elevated walkways like catwalks are equipped with protection from falling objects. The main safety feature of a catwalk to prevent falling objects is a toe board. A toe board, also called a kickplate, is a vertical projection from the walking surface around the edges of the walkway.

Below are the OSHA requirements for toe boards:

1910.29(k)(1) The employers must ensure toe boards used for falling object protection.

1910.29(k)(1)(i) Are erected along the exposed edge of the overhead walking-working surface for a length that is sufficient to protect employees below.

1910.29(k)(1)(ii) Have a minimum vertical height of 3.5 inches (9 cm) as measured from the top edge of the toe board to the level of the walking-working surface.

1910.29(k)(1)(iii) Do not have more than a 0.25-inch (0.5-cm) clearance or opening above the walking-working surface.

1910.29(k)(1)(iv) Are solid or do not have any opening that exceeds 1 inch (3 cm) at its greatest dimension.

1910.29(k)(1)(v) Have a minimum height of 2.5 inches (6 cm) when used around vehicle repair, service, or assembly pits. Toe boards may be omitted around vehicle repair, service, or assembly pits when the employer can demonstrate that a toe board would prevent access to a vehicle that is over the pit.

1910.29(k)(1)(vi) Are capable of withstanding, without failure, a force of at least 50 pounds (222 N) applied in any downward or outward direction at any point along the toe board.

1910.29(k)(2)(i)

Where tools, equipment, or materials are piled higher than the top of the toe board, paneling or screening is installed from the toe board to the mid-rail of the guardrail system and for a length that is sufficient to protect employees below. If the items are piled higher than the mid-rail, the employer also must install paneling or screening to the top rail and for a length that is sufficient to protect employees below; and

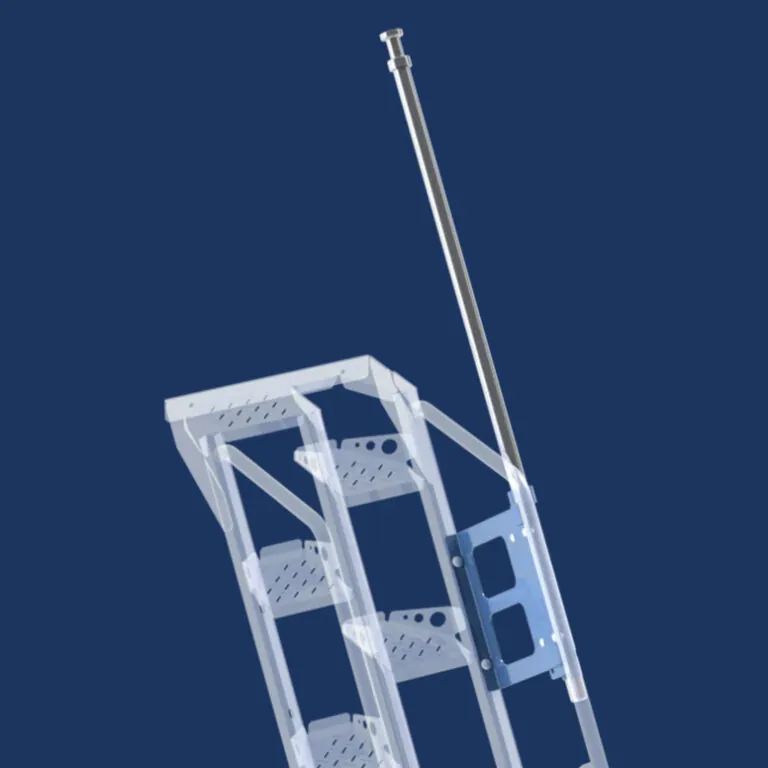

OSHA catwalk opening requirements

The OSHA catwalk opening requirements are found under OSHA section 1910.28 Duty to have fall protection and falling object protection. Catwalks may have floor holes within the walking surface, or vertical openings near the edge of the the walking surface. These holes and openings must be protected by a fall protection system to prevent employees from falling.

An Opening is a gap or open space in a wall, partition, vertical walking-working surface, or similar surface that is at least 30 inches high and at least 18 inches wide, through which an employee can fall to a lower level. Examples of vertical openings are wall openings, chute openings, and window openings.

A Hole means a gap or open space in a floor, roof, horizontal walking-working surface, or similar surface that is at least 2 inches in its least dimension. A hole is an opening in the floor. Examples of holes are drains, large cracks, broken floor boards, chutes, and pits.

For vertical wall openings or other vertical openings, OSHA section 1910.28(b)(7) states that where the inside bottom edge of the opening is less than 39 inches above the walking-working surface and the outside bottom edge of the opening is 4 feet or more above a lower level is protected from falling by the use of a guardrail system, safety net system, travel restraining system, or personal fall arrest system.

For floor holes in a catwalk or other walking surface, OSHA requires that employers provide a means of fall protection around these areas.

1910.28(b)(3)(i) Each employee is protected from falling through any hole (including skylights) that is 4 feet (1.2 m) or more above a lower level by one or more of the following

1910.28(b)(3)(i)(A) Covers

1910.28(b)(3)(i)(B) Guardrail systems

1910.28(b)(3)(i)(C) Travel restraint systems; or

1910.28(b)(3)(i)(D) Personal fall arrest systems.

Section 1910.28(b)(3)(ii) requires that each employee must be protected from tripping into or stepping into or through any hole that is less than 4 feet above a lower level by covers or guardrail systems.

Section 1910.29(b)(13) defines the need for self-closing gates around holes. When guardrail systems are used around holes that serve as points of access (such as ladderways), the guardrail system opening must have a self-closing gate that slides or swings away from the hole, and is equipped with a top rail and midrail or equivalent intermediate member that meets the requirements in paragraph (b) of this section

Final points

Industrial catwalks can greatly improve the layout and efficiency of work areas to provide elevated access for workers to equipment, mechanical, and maintenance areas. There are many design and safety variables to consider when choosing to install a catwalk system. Knowing the many OSHA regulations for these elongated industrial work platforms or walkways can help make sure you are in compliance and are providing a safe work environment for employees.

Resources

OSHA 1910 Walking-working surfaces Scope and definitions

OSHA 1910 Walking-working surfaces general requirements