Alternating tread stairs are the safest and most comfortable space saving stairs for industrial and commercial applications. To maximize floor space, designers need to know when and where to use alternating tread stairs to get the most benefit.

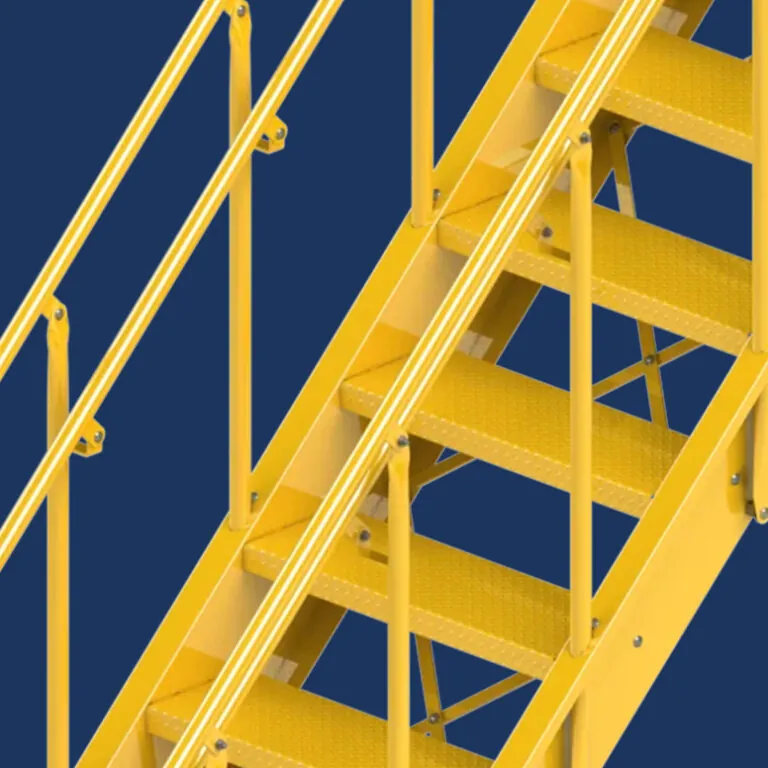

Steep Angle Stair Saves Space

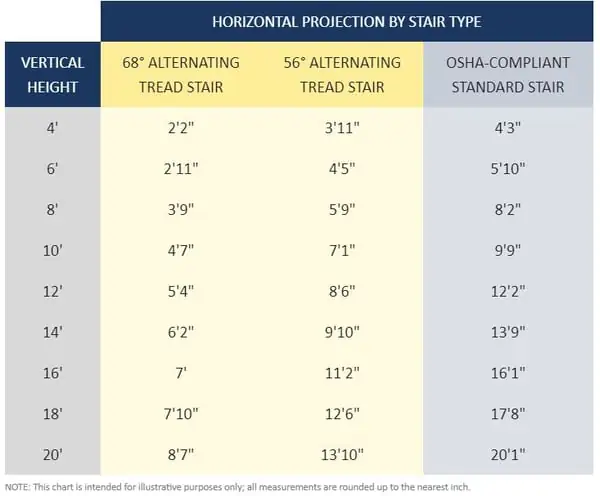

As a steep stair solution, alternating tread stairs save a significant amount of floor space vs a standard stair design. The space savings increases the steeper the angle and the higher the floor-to-floor height of the stairway. Alternating tread stairs come in two different angles, 56 degree and 68 degree. A typical standard stair varies anywhere from 30 degree up to 45 degrees. The chart below shows the space saved using the

56 degree and 68 degree stair angles over various floor heights. 68 degree stairs use less than half the floor space as

45 degree OSHA stairs.

OSHA and IBC Use of Alternating Tread Stairs

When is it ok to use alternating tread stairs? According to OSHA 1910.25, alternating tread stairs can be used in the following scenario:

§1910.25(b)(8) Spiral, ship, or alternating tread-type stairs are used only when the employer can demonstrate that it is not feasible to provide standard stairs OSHA

In the Federal Register / Vol. 81, No.223 OSHA provides a little more clarification: “OSHA believes that the language in the final rule gives employers greater flexibility (than the previous language.) The final rule limits the use of non-standard stairs to those circumstances where, based on specific case-by-case evaluations and demonstrations, it is not possible to use standard stairs.” So space-limitations is an acceptable use for alternating tread stairs according to the OSHA rules.

IBC section 1011 allows alternating tread stairs to be used as a means of egress to unoccupied roofs, to mezzanines not more than 250 square feet and to areas that serve not more than 5 occupants, to guard towers, observation stations, or control rooms not more than 250 square feet in area. Alternating tread stairs can also be used as a secondary means of egress.

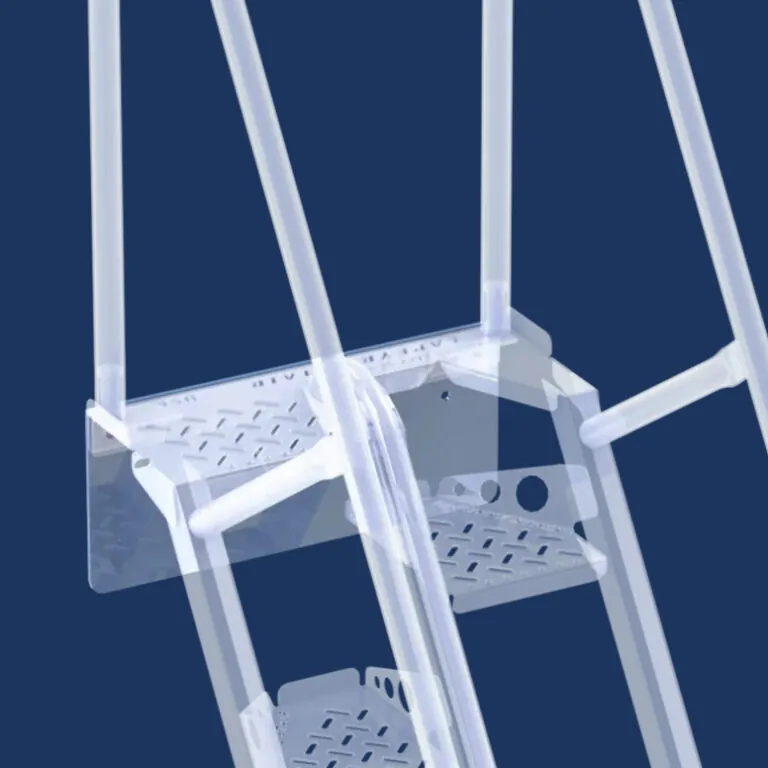

Space Restricted Applications

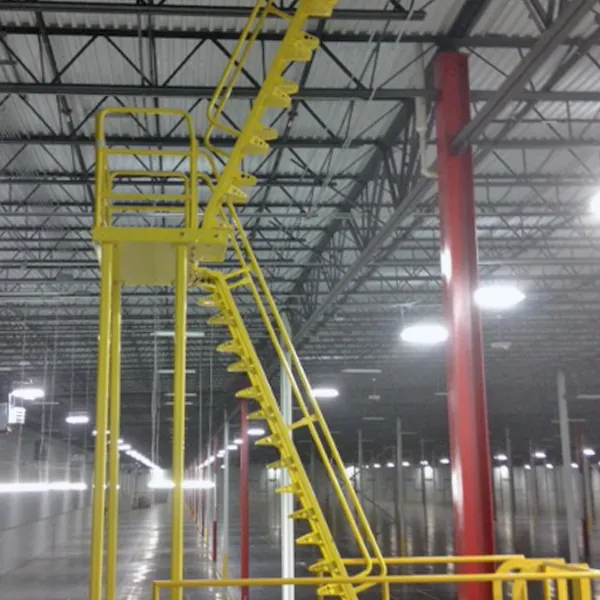

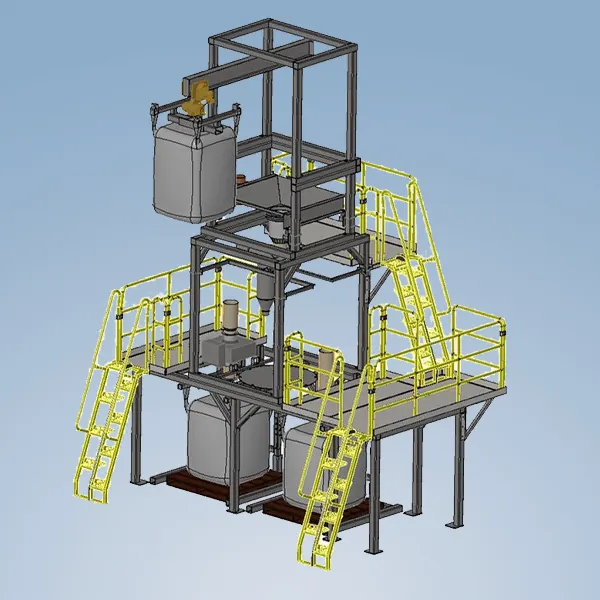

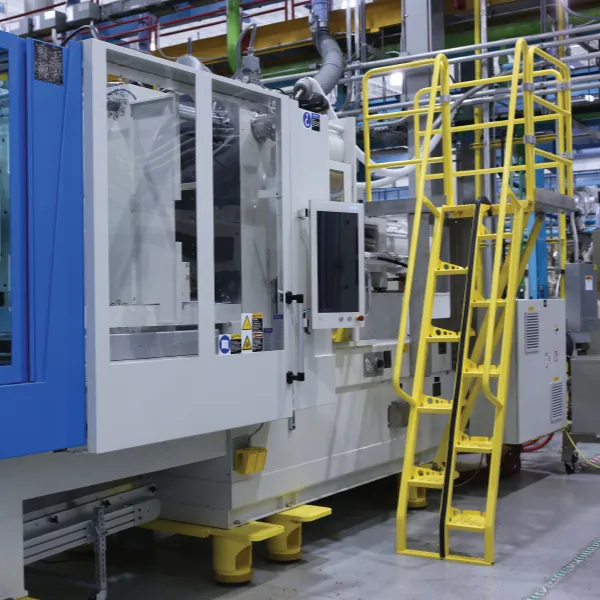

Space limitations can occur almost anywhere. Below are examples of the most common applications with space restrictions. As you can see, there are many different applications that require a space saving stair like the alternating tread stair.

Space Restricted Building Access

Means of Egress for Small Storage Mezzanines

Secondary Means of Egress for Large Mezzanines

Secondary Means of Egress for Plant Offices

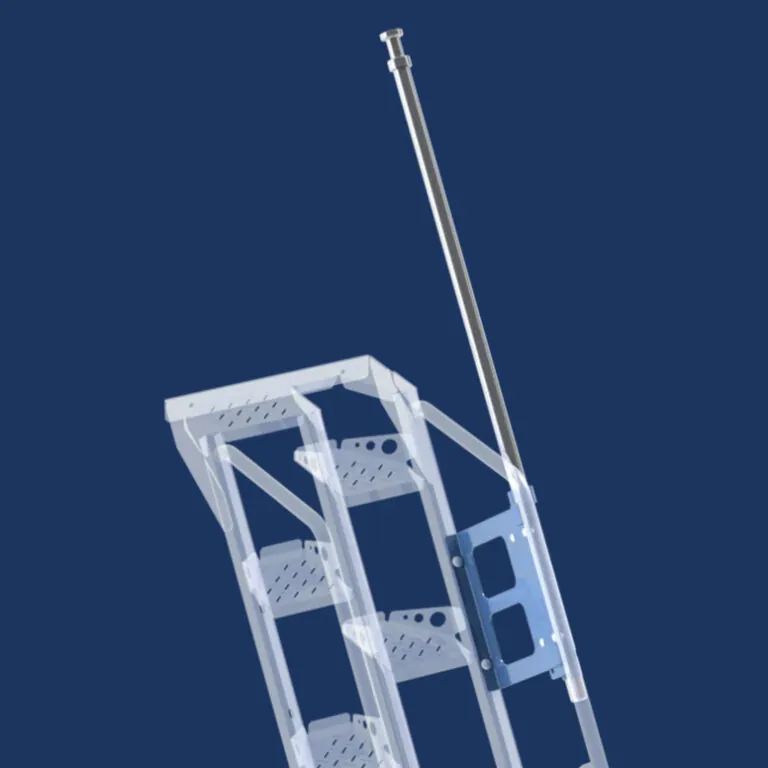

Roof Hatch Access

Exterior Roof Access

Roof Access Towers

Rooftop Equipment Access

Roof Parapet Crossover Stairs

Equipment Storage Platforms

Maintenance Areas

Pits

Space Restricted Equipment Access

Conveyor equipment

Crossover Stairs

Work Platforms

Bulk Handling and Bagging Equipment

Dry Material Metering Equipment

Batch Processing Equipment

Water Treatment Equipment

Air Handling Equipment

Blast Cleaning Equipment

Metal Processing Equipment

Baghouse and Dust Collector Equipment

Food Manufacturing Equipment

Plastic Manufacturing and Injection Molding Equipment

Paper Manufacturing Equipment

Electrical Equipment Access

Chemical Storage Tanks

Exterior Tanks

Holding Tanks