When it comes to stair safety, environmental, behavioral, and design factors can all contribute to the risk of using a stairway. Employers must limit all three factors to ensure that stairways are safe for employees to use. Ensuring that stairways are designed for code compliance is a good first step. This post will help you understand design induced risk factors of stairways and how to limit them in your facility.

Much research has been conducted on the design of stairways for safety. In Chapter 13 of Fall Protection and Prevention: Principles, Guidelines, and Practices Hisao Nagata identifies the following factors to be significant design induced risk factors of stairways:

- As tread depth becomes narrower than a foot length, missteps become more frequent. Shorter treads give insufficient foot support and cause postural instabilities

- Inconsistent dimensions of tread or rise cause missteps

- Slippery and rough treads cause missteps

- Inappropriate combinations of tread depth and riser height will cause an awkward walking mode and missteps

- One or two isolated steps may be located in walkways, which provide no cues to their presence

- There may be no graspable, reachable handrail

- There may be a discontinuous handrail

- There may be confusing color patterns on the tread or poor visibility of nosings

- The nosing strip may project above the tread

Let’s explore each of these in detail.

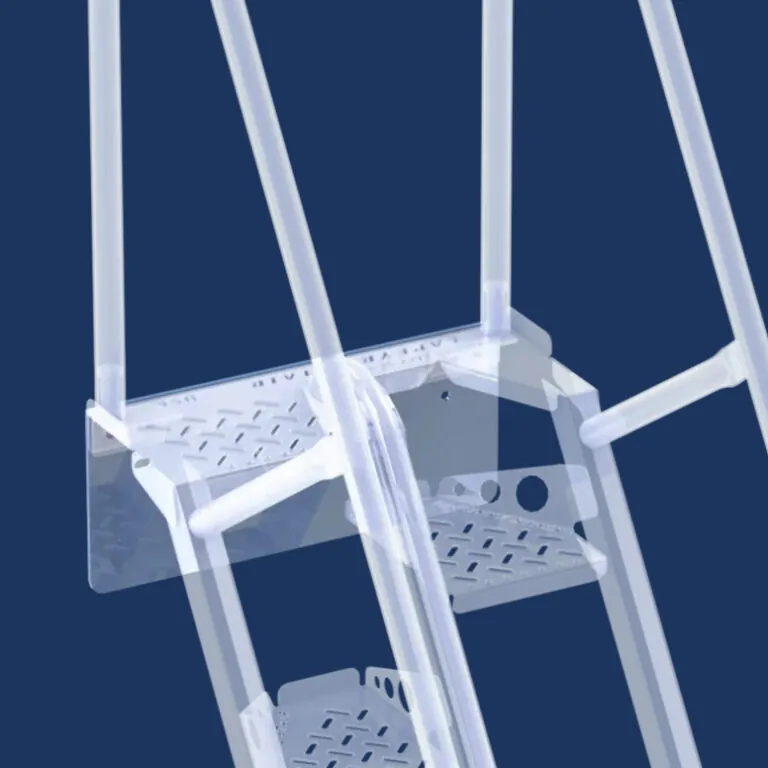

Narrow stair tread depth

We previously wrote an entire post on the subject of stair tread depth. Studies have shown that missteps and likelihood of falls increase with stairs that have less tread depth as the tread becomes smaller than a foot length.  Tread depth length should be sufficient to accommodate the contact length of a user’s shoe on a tread enough to keep the user standing upright and balanced. Treads that are too short force the stair user to either rest only part of the fool on each tread or to twist the foot unnaturally; both of these cases increase the risk of a misstep. An 11″ tread depth accommodates the foot length of more than 95% of the general population. For standard stairways, IBC 1011.5.1 requires an 11″ minimum tread depth. OSHA 1910.25(c)(3) requires a 9.5″ minimum tread depth.

Tread depth length should be sufficient to accommodate the contact length of a user’s shoe on a tread enough to keep the user standing upright and balanced. Treads that are too short force the stair user to either rest only part of the fool on each tread or to twist the foot unnaturally; both of these cases increase the risk of a misstep. An 11″ tread depth accommodates the foot length of more than 95% of the general population. For standard stairways, IBC 1011.5.1 requires an 11″ minimum tread depth. OSHA 1910.25(c)(3) requires a 9.5″ minimum tread depth.

Steep stairs and ships ladders have greatly reduced tread depth. OSHA 1910.25(e)(3) allows a minimum 4″ tread depth for ship stairs, while IBC requires 5″ tread depth for ships ladders. OSHA 1910.25(f)(3) requires that alternating tread stairs have a minimum tread depth of 8.5″, more than 2x the tread depth as ship stairs. The greater tread depth of alternating tread stairs results in significantly fewer missteps.

Inconsistent tread or riser dimensions

Dimensional inconsistencies in treads and risers can impact a person’s gait and balance while walking up or down the stair. Studies have shown that an irregularity as little as 0.25 inches between adjacent risers can disrupt a person’s step enough to cause a fall. In a review of 9 case studies of Falls on Stairs, inconsistent step geometry was a contributing factor in 5 cases. OSHA 1910.25(b)(3) requires that stairs have uniform riser heights and tread depths between landings. IBC 1011.5.4 also requires uniformity with an allowable tolerance of 3/8″ between the largest and smallest riser height and tread depth.

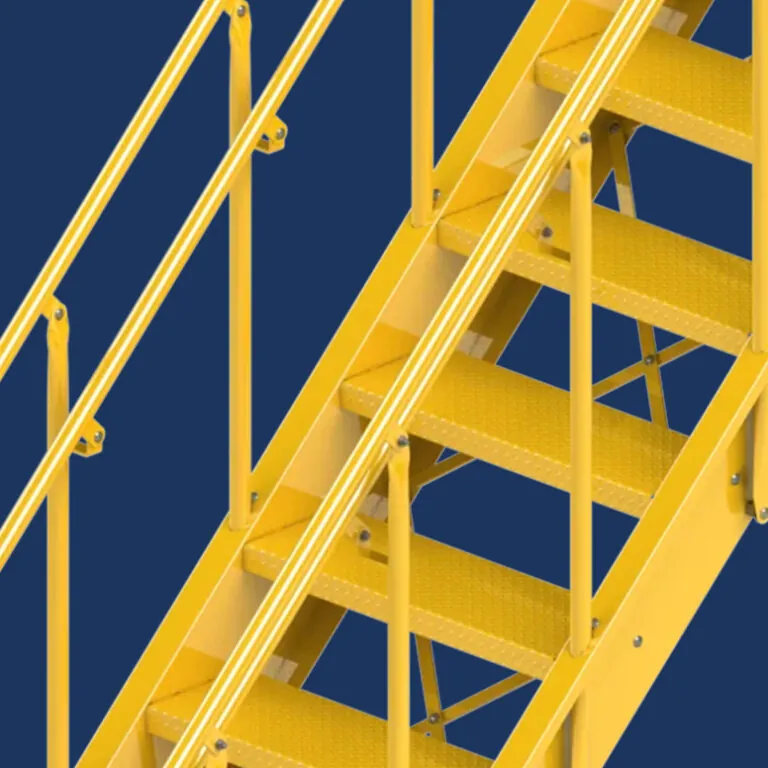

Slippery and rough treads cause missteps

Slips and falls are primarily caused by a slippery surface. Non slip surfaces can help prevent slippery conditions. Slip resistance is measured by the coefficient of friction between the walking surface and the user’s foot. Non slip metal stair treads with a high coefficient of friction can help reduce slips and falls on stairways. IBC and ADA require a slip resistant surface for stairways. OSHA 1910.22(a)(3) requires that walking-working surfaces are maintained free of hazards such as sharp or protruding objects, loose boards, corrosion, leaks, spills, snow, and ice.

Slips and falls are primarily caused by a slippery surface. Non slip surfaces can help prevent slippery conditions. Slip resistance is measured by the coefficient of friction between the walking surface and the user’s foot. Non slip metal stair treads with a high coefficient of friction can help reduce slips and falls on stairways. IBC and ADA require a slip resistant surface for stairways. OSHA 1910.22(a)(3) requires that walking-working surfaces are maintained free of hazards such as sharp or protruding objects, loose boards, corrosion, leaks, spills, snow, and ice.

Inappropriate combinations of tread depth and riser height

In a study in 1990, researchers looked at how subjects navigated stair with different treads and riser dimensions. The optimum riser height was 7.2 inches and the optimum tread depth was 11 or 12 inches. Deviations in riser height were shown to be more difficult for users. IBC 1011.5.2 requires risers to be between 4 inches and 7 inches. OSHA 1910.25(d)(2) allows a maximum 9.5″ riser height.

Isolated steps in a walkway

John Templer wrote the book on stairs and is perhaps the most famous of stair safety researchers. In 1976 he published “An Analysis of the Behavior of Stair Users”. In this study, it was observed that very short stairways were associated with higher trip incidences. This observation has been shown in other studies. The ASTM F1637 Standard Practice for Safe Walking Surfaces recommends avoiding short stairs of 3 or fewer risers when possible.

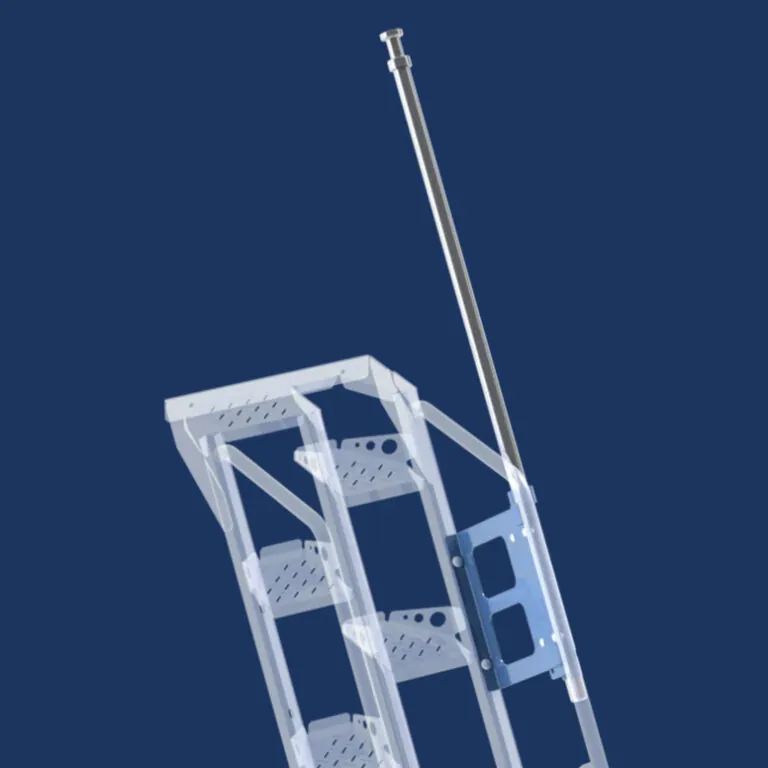

No graspable or reachable handrail

The presence of a handrail is important for stair safety. Observational studies have shown that even when users do not use handrails while walking up or down a stair, having one within reach in case of a loss of balance can prevent a fall. In the 2017 Update to walking-working surfaces, OSHA introduced the requirement for a separate handrail on stairways. IBC 1011.11 requires that stair flights have handrail on each side.

The presence of a handrail is important for stair safety. Observational studies have shown that even when users do not use handrails while walking up or down a stair, having one within reach in case of a loss of balance can prevent a fall. In the 2017 Update to walking-working surfaces, OSHA introduced the requirement for a separate handrail on stairways. IBC 1011.11 requires that stair flights have handrail on each side.

Discontinuous Handrail

A discontinuous handrail has a gap or opening in the handrail. The gap may cause a user to reach for a handrail and be unable to find it. With no handrail to grasp, a loss of balance may result in a fall. ADA requires a continuous handrail. IBC 1014.4 requires that the handrail gripping surface by continuous, without interruption by newel posts or other obstructions.

A discontinuous handrail has a gap or opening in the handrail. The gap may cause a user to reach for a handrail and be unable to find it. With no handrail to grasp, a loss of balance may result in a fall. ADA requires a continuous handrail. IBC 1014.4 requires that the handrail gripping surface by continuous, without interruption by newel posts or other obstructions.

Confusing color patterns on tread or poor visibility of nosings

Contrast strips on nosings help users identify the presence of a step edge. Studies have shown that stair edge contrast nosings have a beneficial effect on balance control in older adults. Other studies have shown high contrast nosings flush with the step edge improve foot clearance over the step.

In a review of 9 cases of falls on stairways, inadequate visual  information of step edges were found in 5 cases. ADA recommends providing visual contrast on at least the top and bottom steps. IBC 1011.5.4.1 requires distinctive marking strips for nonuniform risers that are allowed at the bottom or top of stairways adjoining a sloped public way. IBC 1025.1 requires luminous step edge markings on stairways in high rise buildings.

information of step edges were found in 5 cases. ADA recommends providing visual contrast on at least the top and bottom steps. IBC 1011.5.4.1 requires distinctive marking strips for nonuniform risers that are allowed at the bottom or top of stairways adjoining a sloped public way. IBC 1025.1 requires luminous step edge markings on stairways in high rise buildings.

Nosing strip may project above the tread

Nosings that project too high above the stair tread surface may lead to users tripping or misstepping over uplifted or protruding strips. IBC 1011.5.5.1 allows a maximum leading edge projection of the nosing to be 1-1/4″ from the tread below. IBC 1011.7.1 requires stairway treads to have a solid surface.

Conclusion

Many factors affect stair safety. Lapeyre Stair is committed to helping our customers ensure their stairs are designed for maximum safety and code compliance.