The design combinations for stair railings are nearly endless. A common railing design uses balusters to form a balustrade. The balusters serve as one of the most important design features of the railing. Different types of balusters can be used to create a unique style and function for the stair railing.

What are the different types of balusters?

The types of balusters vary depending on the environment, the material used, and the look desired for the staircase. Balusters can be round, square, flat, rectangular, and a variety of custom designed shapes. Common baluster materials include metal, wood, stone, wrought iron, and even concrete.

A baluster style railing is on of the most popular types of railings for stairs. Baluster styles can range from the purely functional vertical steel pickets used in commercial steel stairs or bolted steel stairs to the ornate, hand-carved stone balusters found in ancient cathedrals. A spindle, one of the stair parts names that commonly gets confused with baluster, is a type of long, thin baluster.

Metal balusters

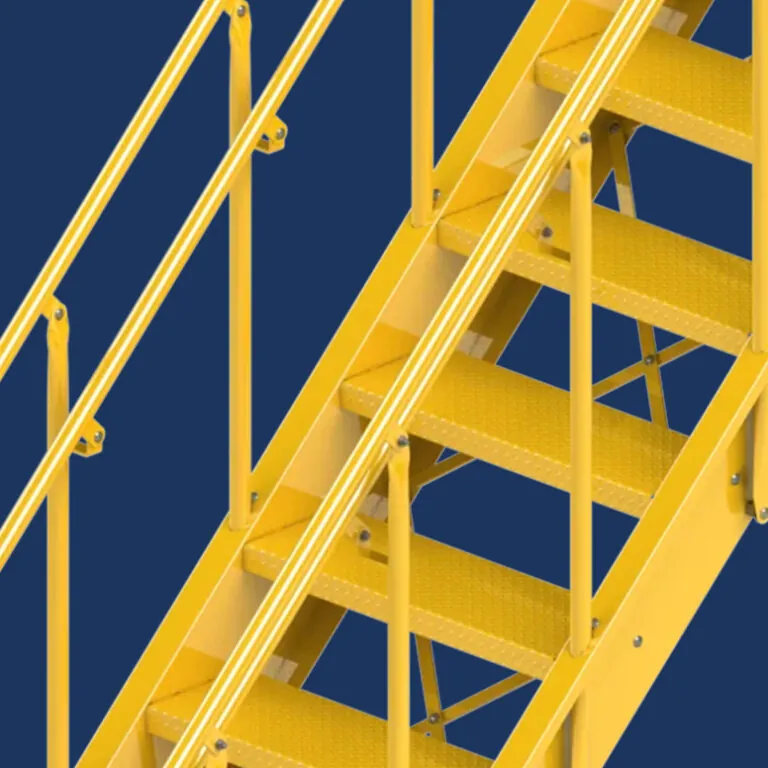

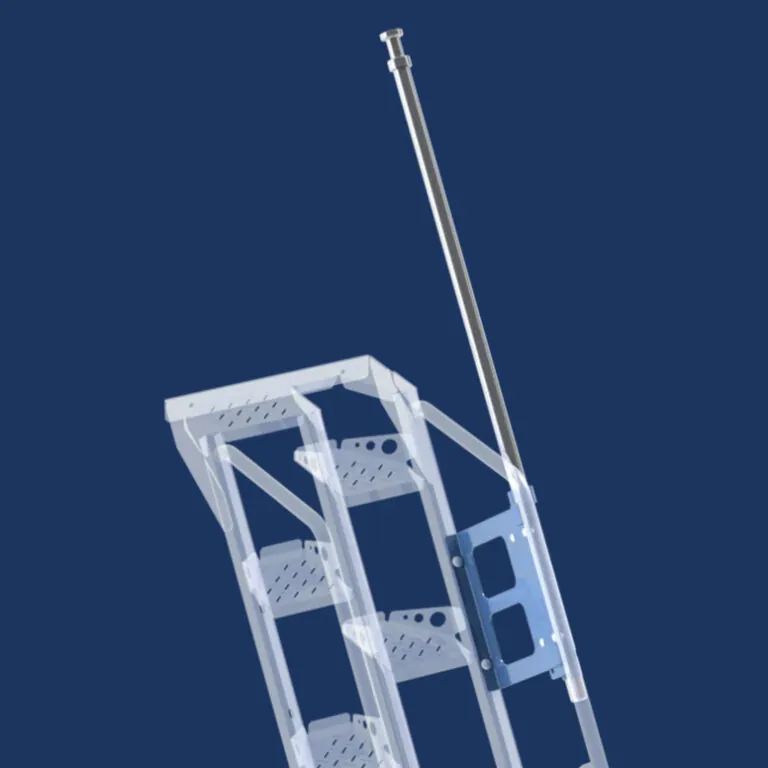

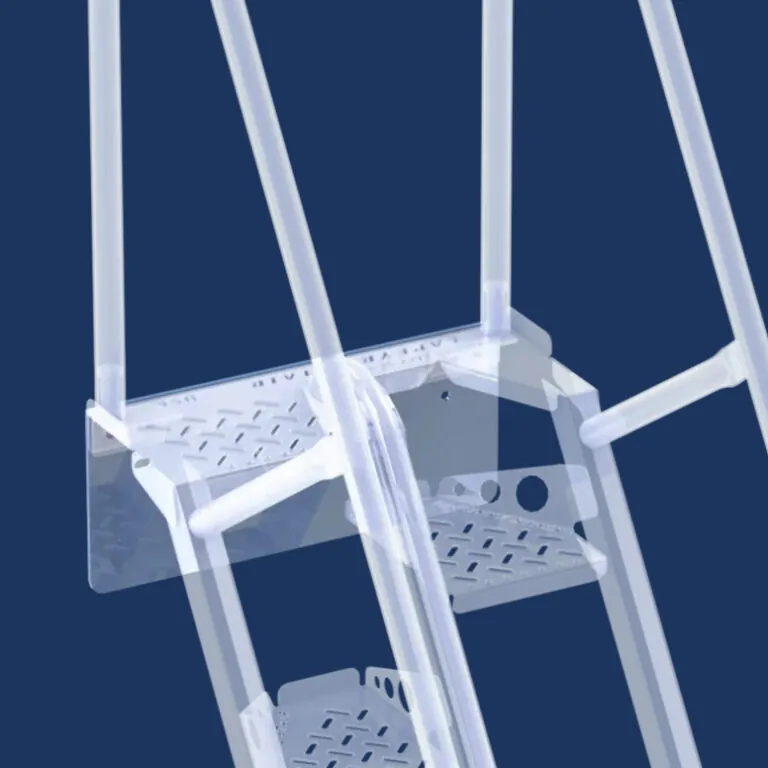

Metal balusters come in a wide range of sizes and styles. Usually made of metal tubes, pipes, rods or bars, these balusters are often incorporated into in a multi-line railing design for egress stairs. Metal balusters can be made of steel, aluminum or wrought iron and are often used with wood stairs as architectural elements.

Metal balusters come in a wide range of sizes and styles. Usually made of metal tubes, pipes, rods or bars, these balusters are often incorporated into in a multi-line railing design for egress stairs. Metal balusters can be made of steel, aluminum or wrought iron and are often used with wood stairs as architectural elements.

Metal baluster applications

Metal balusters are a great option for industrial applications. Railings with a center mid-rail to meet IBC and OSHA building codes incorporate metal pipe or tube balusters.

Metal balusters are also common in both commercial and residential settings and can be used indoor and out. Hollow tubes and pipes are best for interior stairs, while solid rods or bars are better for exterior stairs. Commercial picket railing is a type of baluster railing.

Metal baluster advantages and disadvantages

Pros

- Metal balusters are strong and durable.

- They can withstand the natural elements quite well and can last a long time even with exposure.

- Metal is malleable enough that it can be formed and made into different shapes and designs to achieve the desired look of the homeowner or contractor.

- With powder coating, a variety of colors of metal balusters are available, including satin black and antique bronze.

- Balusters made of metal are relatively maintenance free.

Cons

- Except aluminum which naturally resists corrosion, most metals rust easily unless treated. Steel can be galvanized or powder coated to protect against corrosion, while wrought iron balusters can be sealed and coated to prevent rust.

- Metal balusters tend to be more expensive than those made of other materials.

Wood balusters

Wood is one of the most popular materials for balusters. Wood balusters were popularly used in the past and are associated with more traditional, classic staircase designs. Today, wooden balusters can be combined with other materials, like metal or glass, to create a modern, sophisticated look.

Wood baluster applications

Wooden balustrades are often used in more traditionally styled homes and in the interior of commercial buildings. However, they can also be used outdoors if treated and maintained correctly.

Wood baluster advantages and disadvantages

Pros

- Since wood is a natural material, wood balusters bring a sense of warmth to the staircase.

- Many different wood species, including red oak and poplar, can be used for balusters. They can be stained or painted to match the surrounding environment.

- Wood balusters are available in a variety of shapes and styles including turned, fluted, twisted, braided square, octagonal, carved and more.

Cons

- While typically long lasting, especially if varnished or used indoors, wood can degrade or rot over time.

- Wood balustrades are susceptible to pests such as woodworm or termites, especially if used outdoors.

- Wood balusters are not as strong as metal or concrete balusters.

- To avoid problems like warping or pest damage, wood balusters must be maintained properly. Indoor balusters can be oiled and wiped, while outdoor railing must be sealed or treated to avoid damage.

Stone balusters

Natural stone balusters have been used in staircases across the globe for many centuries. Today, stone balusters are still a popular choice. Both natural stone and precast stone balusters are available in a wide assortment of styles to create a staircase with beauty and style.

Natural stone balusters have been used in staircases across the globe for many centuries. Today, stone balusters are still a popular choice. Both natural stone and precast stone balusters are available in a wide assortment of styles to create a staircase with beauty and style.

Stone baluster applications

From terraces and porches to sweeping stairways, stone balustrades have been incorporated in fine architecture to create enduring elegance. Today, stone balusters are typically used in residences and commercial buildings, like banks and museums. They can be used both indoor and out.

Stone baluster advantages and disadvantages

Pros

- Natural stone provides a genuinely beautiful appearance, while precast stone balusters are made in an assortment of stone-like colors.

- Natural stone balusters are extremely durable and can literally last for thousands of years.

- Railings made from natural stone require little to no maintenance.

- If used outside, stone balusters can complement the natural landscape nearby.

Cons

- Because of their heavy weight, natural stone balusters may be difficult or require special equipment to install.

- Natural stone balusters are more expensive than precast stone balusters.

- While precast stone balusters look and feel like natural stone, they are not as durable and are more prone to chip and crack due to exposure in outdoor environments.

Concrete balusters

Concrete balusters are usually part of precast concrete balustrade systems. These systems are quite versatile as they available in a wide array of colors, textures and eye-catching designs.

Concrete balusters are usually part of precast concrete balustrade systems. These systems are quite versatile as they available in a wide array of colors, textures and eye-catching designs.

Concrete baluster applications

Concrete balusters are normally found outside of homes and commercial buildings. They can be used for porches, front entrances and stairs.

Concrete baluster advantages and disadvantages

Pros

- Concrete is a very durable and sturdy material that guarantees a secure railing for decades.

- Precast concrete balustrades are naturally fire-proof and resistant to temperature changes.

- Precast balustrade systems are easy to assemble and install and show almost no seams when precast color matching caulk is used. Easy installation helps save time and money.

- Unlike railings made from natural stones, stainless steel and marble, concrete balustrades are less costly.

Cons

- With concrete balusters, a sealer needs to be applied from time to time to keep them waterproof and mold free.

- Cracks, which can appear over time, should be addressed immediately to keep the condition from worsening.

- Concrete balusters require regular cleaning to remove dirt, grime and other build up that can occur, especially if located outdoors.

Which kind of baluster design is right for you?

Balusters are the stair parts that most impact how the staircase looks. So, choosing the right baluster shape, style and material is important. Determine how you would like your finished stairway to look. Some balusters will provide a more traditional feel while others will lend a more modern look. Also, take the existing indoor décor or outdoor environment into consideration. Finally, factor in your budget as some materials are more affordable than others.