What are concrete-filled metal pan stairs?

Concrete-filled metal pan stairs are tread systems commonly used in steel stairs for commercial and residential buildings. The concrete-filled tread system consists of a metal pan which is then filled with concrete at the construction job site.

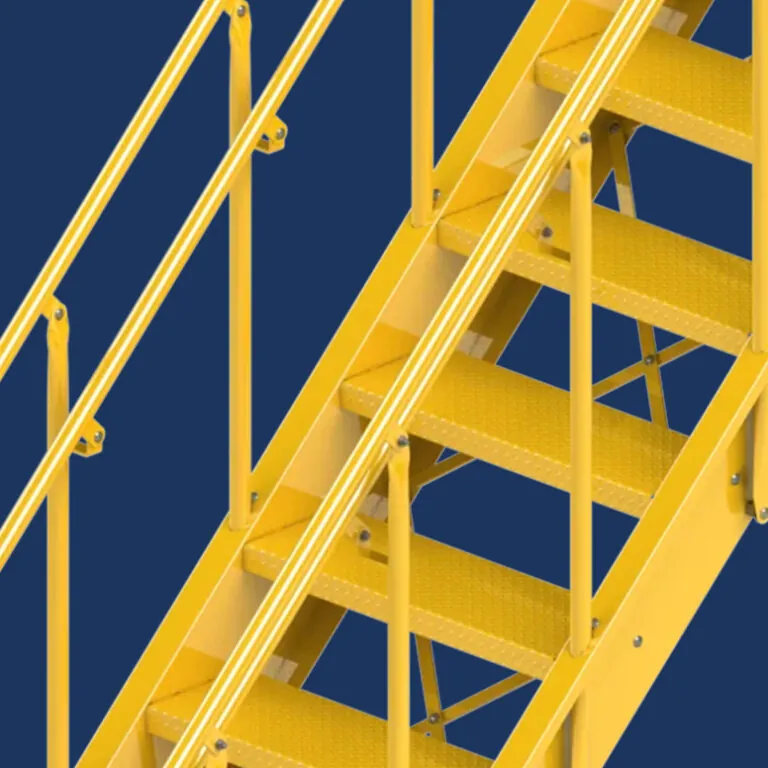

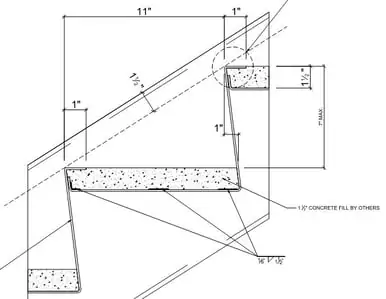

Typically 1.5″ concrete is field-poured into each stair pan individually like the detail and photo below.

|

|

d

What are metal pan stair treads?

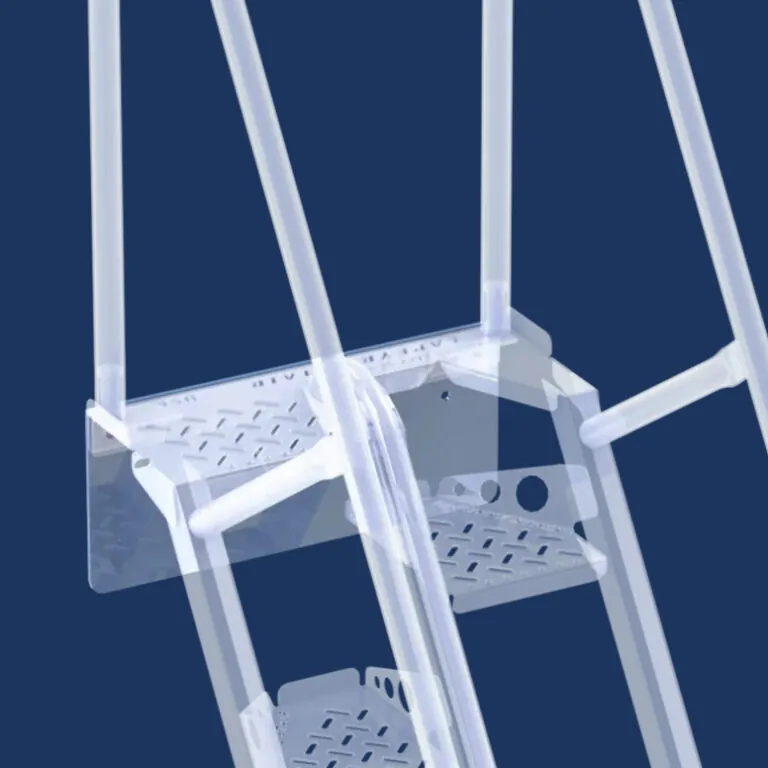

Metal pan stair treads are treads formed into a pan to hold the concrete in place. The metal pan includes a nosing that bends up and back toward the riser to create a concrete form.

The steel pan treads are fabricated and attached to the stair stringers in the manufacturer’s or fabricator’s facility. The concrete is field-poured into the metal pan to establish the walking surface of the stair tread.

Advantages & disadvantages of concrete-filled metal pan stair treads

Pros

Concrete-filled metal pan stair treads have been the standard tread system for steel egress stairs for many decades. The tread system has several benefits which make it a great option for certain egress stair applications.

|

Cons

The main cons of concrete metal pan stair treads is that they are costly, time-consuming, and result in safety hazards at the job site. Field pouring concrete into individual stair treads fails to meet the demands of today’s rapid-paced construction schedules.

Field pouring concrete stair treads is costly, messy, and time-consuming at the job site

Consider that each stair tread contains 1.5″ of concrete. For a 4′ wide stair tread, that’s about 80 lbs of concrete per stair tread. That doesn’t seem like a lot until you calculate for a typical 10-story building with 500 stair pans, and now you have 40,000 lbs of concrete to pour!

A concrete finisher must pour each one of those stair pans individually inside an enclosed stairwell on an uneven stair surface. Often the concrete finishers must hoist the concrete up with buckets or tubs to each pan location. Needless to say, this is not an efficient construction process. Here is a video of a cement finisher finishing concrete stair treads at a job site.

Safety hazard of concrete-filled metal pan stair treads

Metal pan treads are designed with a nosing that extends up and backward toward the riser. The nosing creates a safety hazard for people attempting to use the stairway prior to concrete being poured into the pans.

Because of this safety hazard, OSHA 1926.1052(b)(1) prohibits construction crews from using metal pan stairs during construction unless temporary tread inserts are installed. These can be wood, foam, or any other durable material. Installing the temporary inserts is another time-consuming and costly process, often costing as much as the concrete treads themselves. In many cases crews end up using the stairs without inserts, resulting in safety hazards.

Metal pan stairs with concrete treads cost vs other systems

Concrete-poured metal pan stairs have 3 cost items associated with each tread.

| Cost Item | Concrete-filled metal pan stair tread |

| Metal pan material and fabrication cost | $35 per tread |

| Poured concrete material and installation cost | $35 per tread |

| Temporary inserts | $20 per tread |

| Total Cost | $90 per tread |

Alternatives to concrete-filled metal pan stair treads

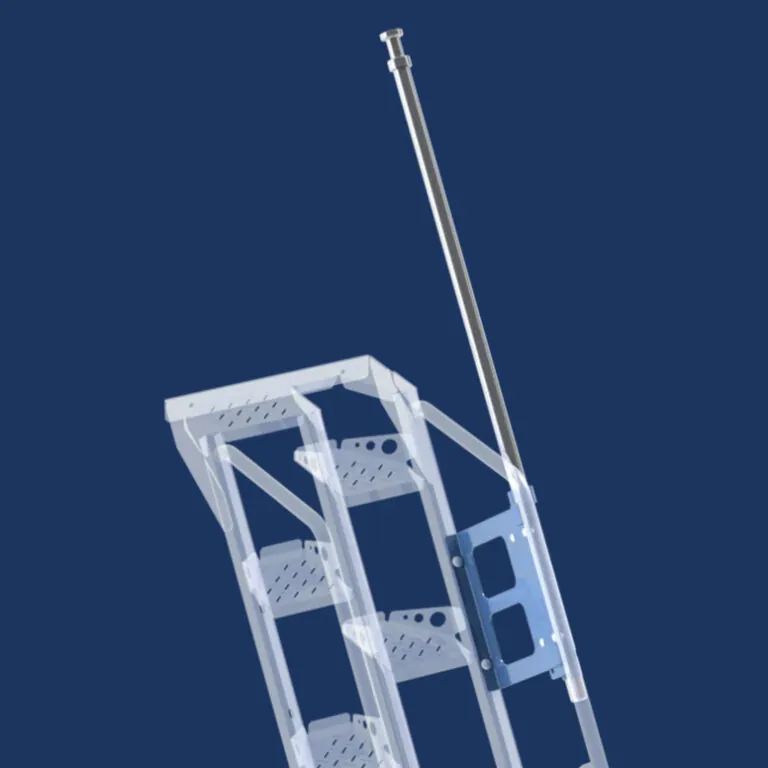

Various alternative tread systems to concrete metal pan stair treads exist with benefits and disadvantages. Lapeyre Stair set out to develop a stair tread system that can outperform concrete for everyone on the project: building owners, architects, general contractors, steel erectors, and finishing trades.

Current standards for alternative egress stair treads

Other alternative tread systems for metal pan stairs provide some of the benefits above but have 1 or more disadvantages. The below chart outlines the cost-benefits of current alternative stair tread systems.

Tread System |

Advantages |

Disadvantages |

|

| Metal diamond plate stair tread | 1. Eliminates concrete pouring in the field

2. Inexpensive and easy to install 3. Been in use for a long period |

1. Durability depends on the coating applied over the metal diamond plate. Inferior coatings may wear off over time

2. Not a very slip-resistant surface 3. Very noisy to foot traffic 4. Not a commercially appealing aesthetic |

|

| Precast concrete stair treads | 1. Eliminates concrete pouring in the field

2. Inexpensive 3. Been in use for a long period |

1. Not an efficient installation process. Requires knock-down stair systems, hauling heavy concrete components up stairwells, and individually fitting and bolting treads into stair stringers.

2. Can be subject to damage and/or cracking during shipping and at job sites.

|

|

| Abrasive epoxy coating over metal stair treads | 1. Eliminates field pouring of concrete

2. Provides a non-slip surface |

1. Subject to damage during construction and requires bolt-on temporary protective coverings, which must have bolt holes filled in with epoxy.

2. Field finishes cannot be applied over the abrasive epoxy. The finish is not commercially appealing. 3. Very limited sound dampening |

Conclusion

Lapeyre Stair was founded on a culture of innovation, and we remain committed to continuously improving standards for our industry. Metal pan stairs have been around for decades but no longer meet the demands of the current construction environment. Our performance tread systems help improve the safety and durability of egress stairs and save time, money and for everyone involved.