Stairs are a key feature of any multi-level structure, including industrial, commercial, and residential buildings. Not only is the design of the staircase important, but also the materials selected for construction.

While stairs can be made of other materials like wood and stone, concrete and steel are most commonly used for the construction of industrial and commercial stairs. This article will look at the similarities and differences between concrete stairs vs steel stairs.

What is the difference between concrete stairs and steel stairs?

The difference between steel stairs and concrete stairs is obviously the base materials used for construction. Steel stairs are made primarily from steel, while concrete stairs are made from concrete. The materials have different costs and benefits for different applications. Steel stairs are generally lighter, stronger, and more design flexible than concrete stairs.

- Steel is an alloy made up of iron, carbon, and other materials. The steel used in staircases is often galvanized with a long-lasting zinc coating to prevent corrosive substances from reaching the steel below. In other cases, stainless steel, which is naturally resistant to corrosion, is used for construction.

- Concrete is made of three components: water, aggregate (rock, sand, or gravel) and powdered cement. The cement acts as a binding agent when mixed with water and the aggregate, which when poured will harden into concrete.

Other differences between steel stairs and concrete stairs are where they are typically found and the types of stairs for which they are used.

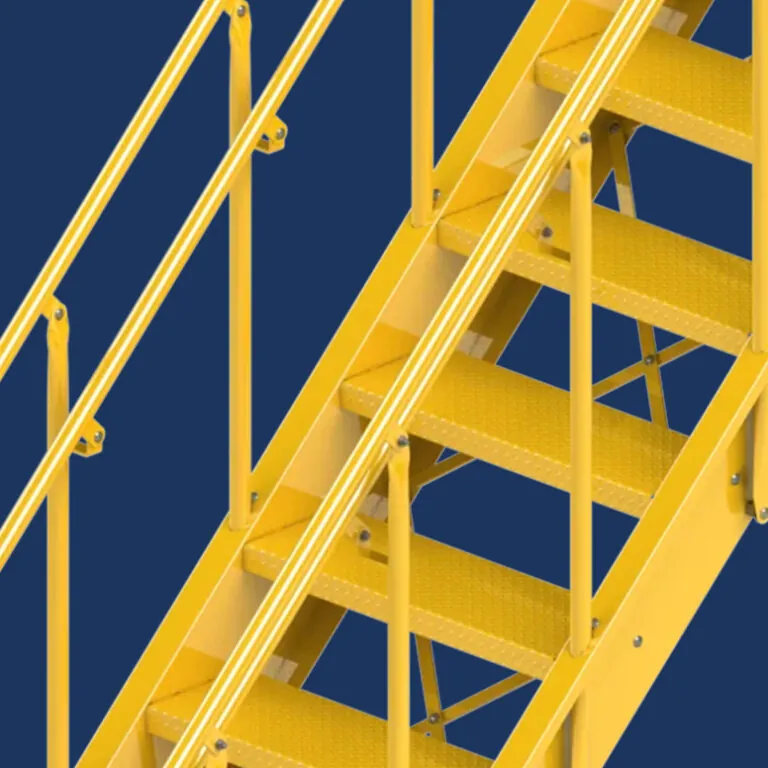

- Steel staircases are popular in indoor settings of homes, businesses and industrial areas. Steel can also be used to build outdoor stairs, especially if made of galvanized or stainless steel. Steel is a popular material for crossover stair, alternating tread and mezzanine stairs in industrial locations, as well as for spiral staircases in homes and commercial buildings.

- Concrete staircases are popular for outdoor use but can also be used as the base of stairs in commercial and residential buildings that are then covered with other materials. Concrete is usually used for more basic types of stairs, such as straight stairs or L-shaped stairs.

Concrete stairs vs steel stairs comparison

| Comparison | Concrete Stairs | Steel Stairs | Best choice |

| Strength & Durability |

|

Steel Stairs | |

| Aesthetics / Design | Steel Stairs | ||

| Cladding | Steel Stairs | ||

| Maintenance | Steel Stairs | ||

| Cost | Steel Stairs | ||

| Sustainability | Steel Stairs |

1. Concrete stairs vs steel stairs strength & durability

Both concrete and steel stairs are strong and durable. Each type of stair has its own advantages and disadvantages depending on the environment in which they are used.

Steel is the sturdiest material that can be used for building staircases. Steel stairs have high tensile strength, meaning they are resistant to breaking under tension. Galvanizing steel to resist corrosion increases its durability, especially in outdoor environments with extreme weather conditions. Steel is almost five times stronger than concrete and is able to bear excessive weight. A steel staircase is stronger than one made of concrete and can also be built with much less material than concrete.

Concrete has a high compression strength, meaning it resists the force of it being pushed together. However, it does not have the tensile strength of steel. Because of this, concrete staircases are sometimes built with hidden metal reinforcing bars or rebar. Concrete stairs can withstand heavy loads and high impact and do not rust in wet conditions. In addition, concrete is fire-resistant, which is why it is often used for fire exit stairwells. Because concrete can absorb vibrations, it is effective in soundproofing, making it ideal for hospital or school staircases. Concrete can retain heat, making it easier to heat stairwells and reduce the cost for heating. While concrete may crack over time, the use of a sealer can help prevent this from happening.

In some cases, steel and concrete are combined to create a staircase which utilizes the advantages of both materials. Steel stairs with concrete treads are often used in commercial and residential buildings. The steel staircase structure provides unparalleled strength, while the concrete treads can be used to reduce noise, provide fire resistance and reduce heating costs.

2. Concrete stairs or steel stairs for aesthetics & staircase design?

When it comes to aesthetics and staircase design, steel is the hands down winner over a concrete structure. Not only is steel strong and durable, it’s also a flexible and adaptable material that can be shaped into a variety of designs including spiral and circular staircases. Today, especially in homes and offices, steel staircases are seen to be modern and contemporary. Wood, tile or stone can be used for other parts of steel staircases, like handrails, stringers and balustrades, to provide a customized and unique look. In addition, steel staircases can be designed with open risers to let in more light and make the environment look more spacious.

Concrete stairs tend to be more functional than aesthetic. While they serve their basic purpose when located outdoors or in hidden areas of a building like a garage or basement, they are not typically seen in the main parts of buildings or living spaces. Just about any type of staircase can be created with concrete. However, the quality of the concrete used for the staircase depends on the temperature, consistency, mix and builder’s experience. And, concrete stairs are difficult to cast or shape with great accuracy.

Steel and concrete can be combined to create a staircase. Steel stairs with concrete steps are often found in parking garages, industrial settings and between floors in apartment buildings. Staircases of this sort tend to be of more simple designs such as straight or switchback. Steel stairs with concrete step tend to be more practical and not used as a design element.

3. Concrete vs steel stairs cladding options

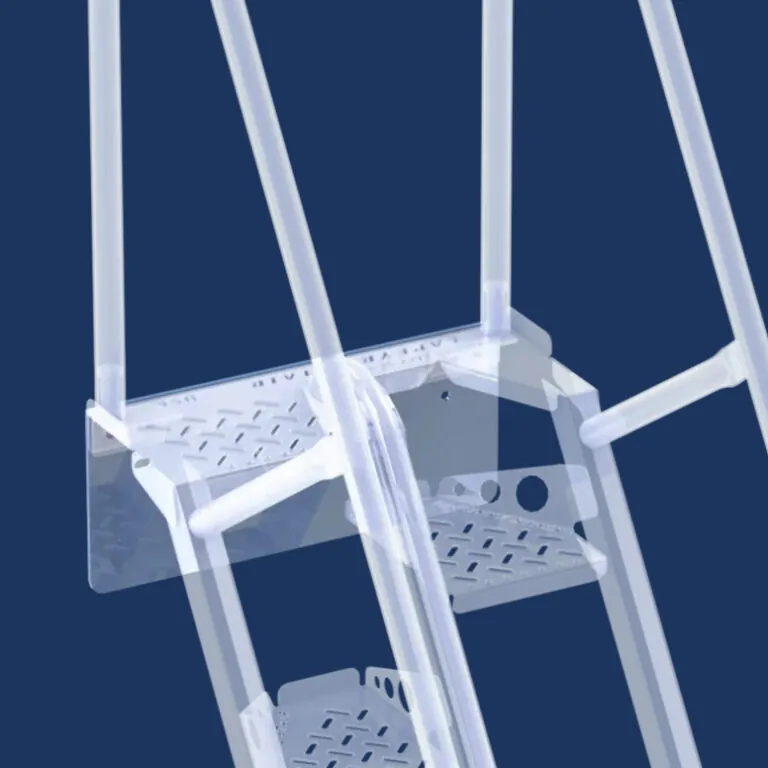

Stair cladding is the process of covering the existing stair treads and risers with another material, such as wood or tile. Stair cladding is often done to give an older staircase a new look without the cost of building an entirely new staircase. Both concrete and steel stairs can be clad or covered with a variety of materials.

Cladding steel stairs is easier and safer than cladding concrete stairs. Since steel stairs tend to be more accurately built, exact measurements can be taken before the cladding components are accurately cut or manufactured off site. With steel stair cladding, installation time is less and the quality tends to be higher.

When cladding concrete stairs, templates need to be taken of the treads and risers to ensure the cladding material fits correctly. Because concrete stairs are rarely 100% accurate, installation of cladding on them can be difficult. In addition, drilling concrete staircases to affix cladding is time consuming and risky. Drilling into a metal reinforcing bar could damage the structural integrity of the concrete staircase.

4. Steel stairs vs concrete stairs: which is easier to maintain?

Both steel stairs and concrete stairs are easy to maintain. Steel stairs require very little maintenance. Outdoor steel staircases can be galvanized to inhibit rusting and corrosion. They can then be cleaned with a pressure washer. If the steel is powder coated, it might be best to use a mop or sponge to avoid damaging the finish. Indoor steel stairs, like mezzanine stairs, can be cleaned by sweeping or mopping with a mild detergent.

Both steel stairs and concrete stairs are easy to maintain. Steel stairs require very little maintenance. Outdoor steel staircases can be galvanized to inhibit rusting and corrosion. They can then be cleaned with a pressure washer. If the steel is powder coated, it might be best to use a mop or sponge to avoid damaging the finish. Indoor steel stairs, like mezzanine stairs, can be cleaned by sweeping or mopping with a mild detergent.

Like metal stairs, concrete stairs are also low-maintenance. Indoor concrete stairs can simply be mopped to remove any dirt. Outdoor concrete stairs can safely be pressure washed to remove grime and other buildup without the risk of damage to the concrete.

5. Steel staircase price vs concrete stairs

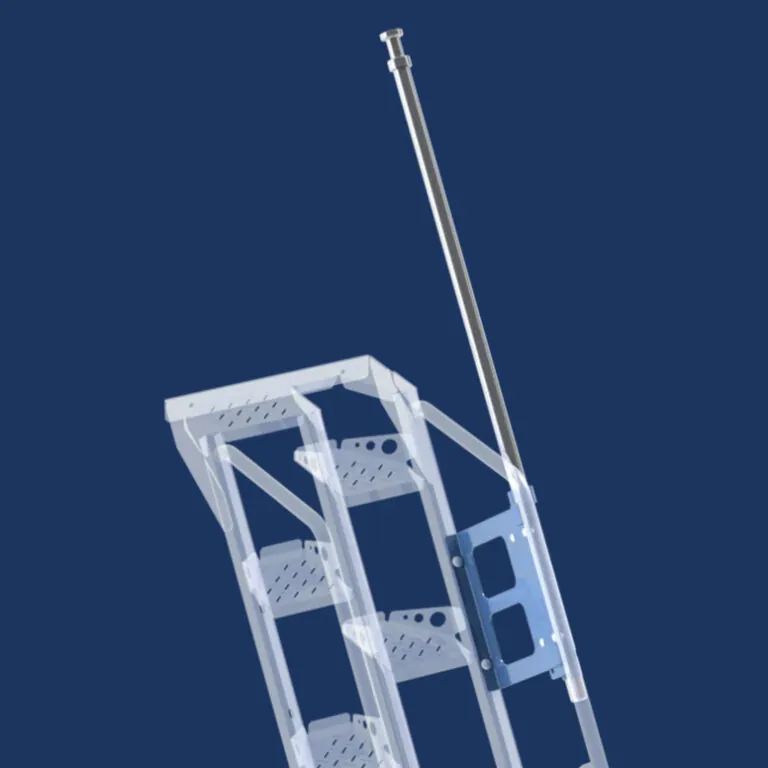

The price of steel staircases is generally less than that of concrete staircases. First, steel is a very cost-effective material to produce. Second, lower labor costs contribute to a lower steel staircase price. Building a staircase with steel takes less time than building with concrete. All of the components of a steel staircase can be manufactured off site and arrive on site at the same time ready to be assembled. Pre-built modular components can also help reduce installation time to keep labor costs low.

Concrete stairs are more expensive than steel stairs due to the high labor costs involved with construction due to the time involved. Building a concrete staircase involves preparing the foundation, building the formwork, placing reinforcing metal bars, and pouring the concrete before finishing and curing it. This process, which is time consuming and messy, ultimately leads to the higher cost of a staircase made of concrete versus one made of

6. Steel stairs vs concrete stairs: which is more sustainable?

Both steel and concrete are extremely sustainable building materials. Steel is 100% recyclable and has a global recycling rate of over 90%. Steel can be used over and over again without compromising its strength and durability. Concrete can be crushed to be reused again in new mixtures making concrete and steel stairs equally sustainable.

Which is better steel stairs or concrete stairs? Our conclusion

And the winner is …. steel. While both steel and concrete stairs are easy to maintain and sustainable, steel stairs offer many advantages over those made of concrete.

- Concrete is strong and durable, able withstand heavy loads and high impact, but steel is almost five times stronger.

- A steel structure also wins when it comes to aesthetics and staircase design. Steel staircases are modern and sophisticated and can be made in almost any shape, while concrete is just plain boring.

- Steel stairs are easier and safer to clad than concrete stairs. Steel stairs are more exact than concrete stairs, which can be damaged by drilling into them to affix cladding.

- Perhaps the most important advantage of a steel staircase is its lower cost. Concrete stairs are extremely labor intensive and therefore much more expensive to build.

In most cases, steel stairs are the ideal solution for any industrial, commercial or residential setting. However, there are cases when concrete stairs or steel stairs with concrete treads may provide an advantage. Since concrete is fire resistant, it may be a good choice for fire exit stairwells. Because it is noise and heat absorbent, concrete stairs may be used for soundproofing and to reduce heating costs.

FAQs

What is the best material for stairs?

The best material for stairs depends on the application and environment. Steel stairs are durable, cost-effective, and easy to install for industrial and commercial stairs in offices, apartments, and factories. Wood stairs are a potentially less expensive option for residential stairs in homes.

Are concrete stairs expensive?

Concrete stairs are often more expensive than steel or wood stairs. the high labor costs involved with construction due to the time involved. Building a concrete staircase involves preparing the foundation, building the formwork, placing reinforcing metal bars, and pouring the concrete before finishing and curing it.

Are metal stairs expensive?

Metal stairs are the least expensive type of stair for applications that need high-strength, durability, and low maintenance. For this reason metal stairs are the preferred material for commercial and industrial egress stair applications like those used in apartments, offices, hotels, and factories.