Staircase construction comes with a host of decisions that have to made. What type of staircase is being built? What are the best materials to use for the various components? What are the best styles use for the different staircase parts? In this article we will examine the best material for stair stringers and the different types of stair stringers.

Staircase construction comes with a host of decisions that have to made. What type of staircase is being built? What are the best materials to use for the various components? What are the best styles use for the different staircase parts? In this article we will examine the best material for stair stringers and the different types of stair stringers.

How many types of stair stringers are there?

When it comes to staircase terminology, most people are familiar with treads (which you step on) and risers (vertical portion of the stair between each tread). But what exactly are stringers?

A stringer is the vertical support board or structural member that runs along each side or center of the staircase. The treads and risers are fixed into the stringer. Different stringers can combine with different types of stair treads to provide an almost endless combination of stair designs.

When located on either side of the staircase, the inner stringer is located against the wall, while the outer stringer is on the side of the staircase open to view. In some cases, the stairway may be in the center of the space with two outer stringers.

Stair stringers are constructed in a variety of materials and styles and finishes that can contribute to the look and functionality of the staircase.

What is the best material for stair stringers?

The best material for a stair stringer depends on both the functionality of the staircase and the look desired. Steel, aluminum and various types of wood are common materials used for stair stringers.

Steel

Steel is an alloy made up of iron, carbon and other materials which can rust. To prevent rusting, galvanized or stainless steel is often used. Galvanized steel features a long-lasting zinc coating to prevent corrosive materials from reaching the steel below. With stainless steel, chromium, nickel, nitrogen and molybdenum are added to enable the steel to resist corrosion.

Steel stair stringer applications

Steel stair stringers are popularly used in staircases in homes, business and industrial areas. Steel stringers can also be used in outdoor applications, especially if made of galvanized or stainless steel. Prefab metal stairs with steel stringers are a good option if the staircase needs to be able to stand up to heavy weight use, such as in industrial applications. Bolt-together metal stairs use formed steel stringers for a functional, lightweight metal stair system. Structural steel stair stringers are used in the design and manufacture of commercial stairs.

Steel stair stringer advantages & disadvantages

Pros

- The primary advantage of using a steel stair stinger is its strength and durability, which enables it to withstand high weight loads and high traffic.

- Steel stringers can be shaped in almost any form, allowing you to create custom staircase options, such as curved and spiral, and also provide a modern look.

- When metal stairs are desired, steel stair stringers are less expensive than those made of aluminum.

- Steel stringers are easier to install than wood stringers as they can just be bolted together.

- Because they are easier to install than wood stringers, prefab steel stringers are also less expensive to install

– whether you are completing a DIY project or hiring a professional. - Steel stair stringers require very little maintenance, whether indoor or out. They are resistant to extreme weather conditions, rot and pests.

- Steel stringers are fire resistant providing an additional safety feature for egress stairs.

Cons

- One of the biggest disadvantages of metal stair stringers is the noise caused when walking up and down the steps.

- While less expensive than aluminum stair stringers, steel stringers are more costly than those made of wood.

- If not done by and expert, the welding seams may look rough and even ruin the appearance of the stair stringer. If you are doing a DIY project, be sure to buy pre-fabricated stringers and make sure the welds are of high quality.

Aluminum

Unlike steel, aluminum is natural element that is corrosion resistant without any type of treatment. Aluminum is also lighter than steel.

Unlike steel, aluminum is natural element that is corrosion resistant without any type of treatment. Aluminum is also lighter than steel.

Aluminum stair stringer applications

Aluminum stair stringers can used in a variety of industrial, commercial and residential staircases.

Aluminum stair stringer advantages & disadvantages

Pros

- Due to its lighter weight, aluminum is less expensive to transport and install than steel, so it’s good to use when the stairs need to be portable

- Installation of aluminum stair stringers is easy, which saves both time and labor costs.

- Aluminum is very malleable and flexible and therefore can be constructed in a variety of shapes – including spiral stairs.

- Due to its natural corrosion resistant layer, aluminum stair stringers are durable and require little maintenance.

Cons

- Aluminum stair stringers are more expensive than those made of steel.

- Because they are lighter weight, aluminum stair stringers are less sturdy than steel.

- Aluminum stair stringers are more prone to nicks and scratches than steel stair stringers.

- The oxide layer of aluminum tends to dull its metallic shine, giving the material a grayish appearance.

Wood

Wood stair stringers come in different types of natural wood including oak, maple and walnut. Stair stringers can also be made from pressure treated or engineered wood. Wood stair stringers can be pre-cut for easier installation or uncut if a custom installation is preferred.

Wooden stair stringer applications

Wood stair stringers are normally found in residential or commercial buildings. In addition to their use as a support structure for the staircase, wood stair stringers add a warm and natural look to the room or environment.

Wooden stair stringer advantages & disadvantages

Pros

- Wood stair stringers are durable and easy to clean.

- Because of the variety of options available, wood is versatile and can compliment both classic and modern looks.

- Pressure treated wood stair stringers are normally used for outdoor deck stairs. The pressure treatment prevents against rot and pests for years and tends to be economical.

- Engineered wood is made from a thin layer of hardwood bonded over high quality ply-wood. Engineered wood provides stability, resists bowing and shrinking, and is more resistant to heat and water than solid hardwood. It is also generally less expensive and easier to install.

Cons

- Unless very high-quality wood is used, you may have issues with it being straight and having an extreme number of knots.

- Solid hardwood can be more expensive than other options, but generally increases the value of your home or building.

- Unlike solid hardwood, engineered hardwood can be refinished only once or twice before the surface hardwood layer is exhausted.

What are the different types of stair stringers?

Just as stair stringers can be made from different kinds of materials, they can also be built in different styles and types. The difference in styles depends on the type of stair design, the function and use of the stair, and the material used for construction of the stairs.

Commercial and industrial stair stringer styles

Commercial and industrial stair stringers are usually made of steel, aluminum, or stainless steel. Common styles for these stair stringer materials include:

- Double stringers (two stringers on outside of treads)

- Center beam stringer (one stringer underneath the tread)

Double stringer

Double stringer

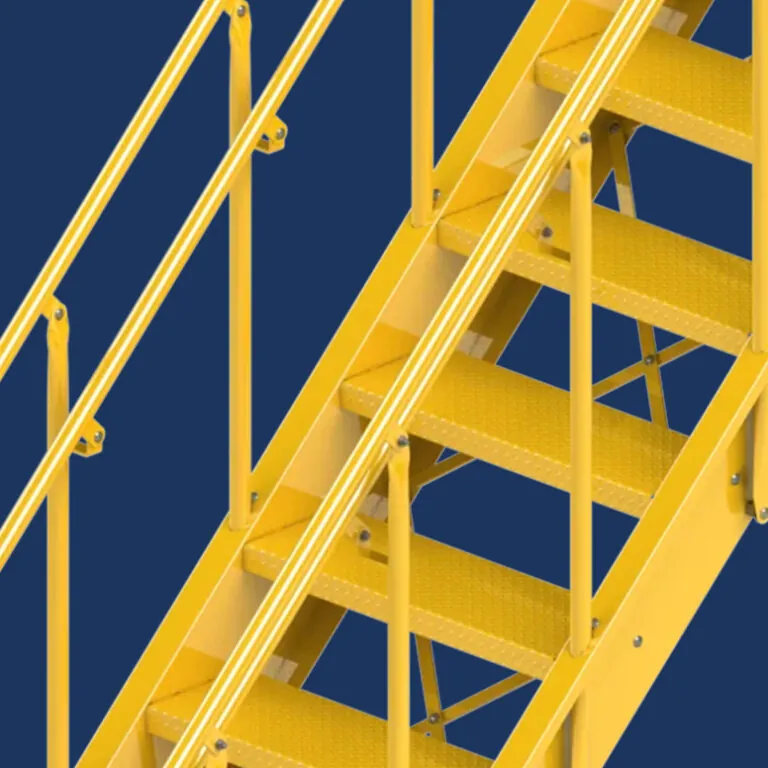

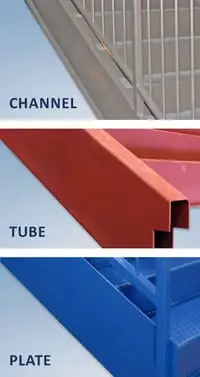

Double stair stringers include two stringers each at the outside of each stair tread. The double stair stringer is the most common stringer style for commercial and industrial stairs. The design is used for prefabricated stair systems and can work with many types of stair railings. Steel stairs designed with double stringers often use structural steel shapes:

commercial and industrial stairs. The design is used for prefabricated stair systems and can work with many types of stair railings. Steel stairs designed with double stringers often use structural steel shapes:

- Channel stringers

- HSS tube stringers

- Plates stringers

Double stair stringer applications

Double stair stringers are commonly used for egress stairs in commercial buildings, for industrial stairs, and for residential metal stairs. The double stringer design provides added support to meet engineering requirements to ensure a safe and durable design.

Double stair stringer advantages and disadvantages

Pros

- Great design for prefabricated stairs to make installation easier

- Flexible and functional design for fire escape stairs and industrial stairs

- Double stringer supports increase the strength of the stair to meet engineering requirements

Cons

- Requires two stringers, which might increase cost

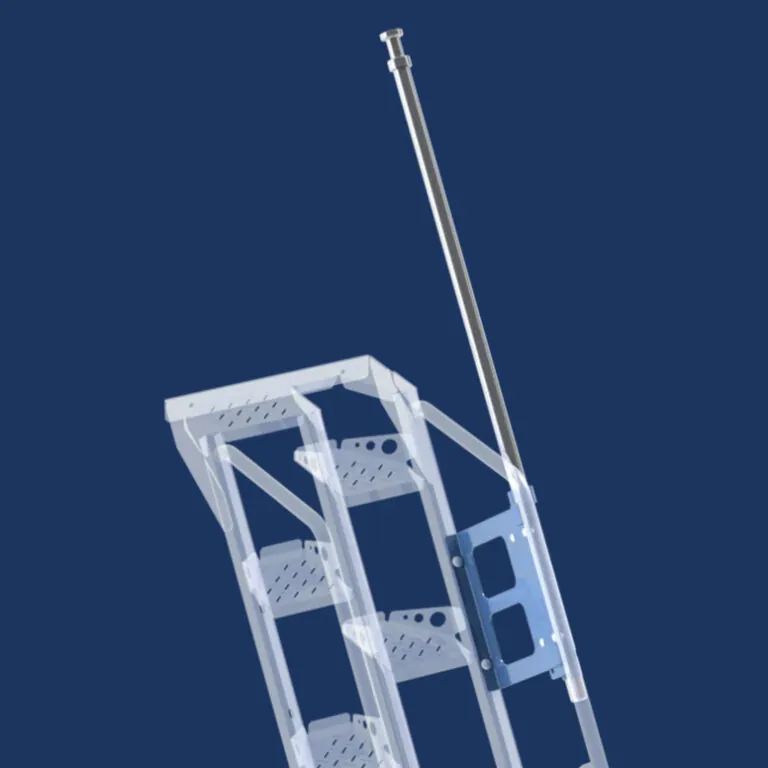

Center beam stringer

Center beam stringers are a type of mono stringer used in high-end feature stairs for offices, hotels, and other highly visible locations. This type of stringer uses a single beam, usually steel or stainless steel, that sits underneath the stair treads and provides the support for the stairs. Steel and stainless steel I-beams or HSS tube are common shapes used to fabricate center beam stringers.

Center beam stringer applications

Center beam stringers are a common type of stringer in monumental and feature staircases. The stringer is attached to the underside of the stair stringers and runs down the center of the flight.

Center beam stringer advantages & disadvantages

Pros

- Provides a high-end design aesthetic for ornamental and feature staircases

Cons

- Typically more expensive to construct and install

Residential stair stringer types

Closed (routed, housed, box or side) stringer

Closed stair stringers are referred to by many different names including routed, housed, side and box stringers. This type of stringer is positioned outside the treads and risers so that the stairs are contained in between the two stringers. Closed stair stringers feature notches in which the treads and risers can be inserted. With this type of stringer, the edge of the tread is not visible and the vertical parts of the handrail (made up of balusters and newels) are typically attached to the top of the stringer.

Closed (routed, housed box or side) stair stringer applications

Closed stair stingers can be used for staircases just about anywhere – in homes, commercial buildings and industrial applications. Closed stair stringers are commonly used for outdoor stairs.

Closed (routed, housed box or side) stair stringer advantages & disadvantages

Pros

- Closed stair stringers can be built with open or closed risers depending on the need and desired look.

- Staircases with closed stair stringers are generally easier and less expensive to build. In many cases, pre-cut stringers are available.

Cons

- Staircases with closed stair stringers tend to provide a more basic and functional look than staircases built with other styles of stair stringers.

Open (cut or sawtooth) stringer

Open stair stringers are also called cut or sawtooth stringers. When viewed from the side the treads are exposed. When open stringers are used in staircase construction, the balustrade supporting the handrail is set directly on top of the steps.

Open stair stringers are also called cut or sawtooth stringers. When viewed from the side the treads are exposed. When open stringers are used in staircase construction, the balustrade supporting the handrail is set directly on top of the steps.

Open (cut or sawtooth) stair stringer applications

Open stair stringers are used in environments where the staircase needs to be visually appealing, including in residences and commercial buildings. They are not usually found in industrial settings.

Open (cut or sawtooth) stair stringer advantages & disadvantages

Pros

- Staircases with open stringers usually provide a more sophisticated and appealing look than closed stair stringers.

- Open stair stringers can also have open or closed risers depending on the function and style desired.

Cons

- A staircase with open stair stringers is more difficult to build and is usually more expensive than a staircase with closed stringers.

- Since the sides of the tread are exposed, they need to be treated to provide an appealing look.

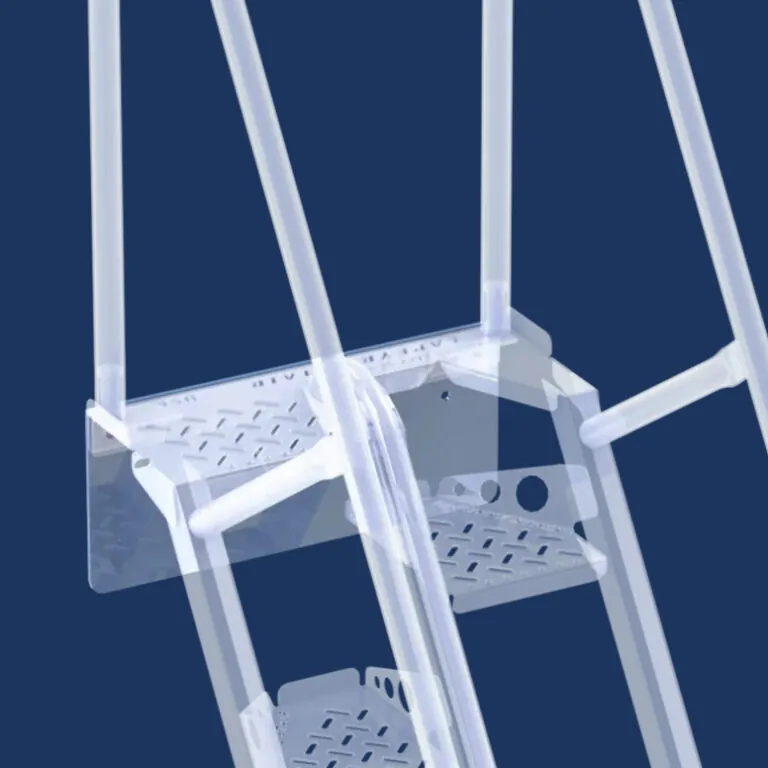

Mono stringer

As the name suggests, a mono stringer staircase uses a single but heavy-duty stringer beneath the center of the treads to support the staircase. Mono stingers are normally metal and welded to each tread with a bracket. All staircases with mono stringers have open risers.

Mono stair stringer applications

Mono stair stringer applications

Mono stair stringers are mostly used in modern homes and office buildings to achieve a contemporary look and are commonly used on spiral staircases.

Mono stair stringer advantages & disadvantages

Pros

- Staircases with a mono stringer provide the most open-air look of any type of stair.

- A variety of staircase styles, such as straight, U-shaped or winder, can be built using a mono stair stringer.

- Mono stair stringers are extremely strong and durable and easily be designed around most building codes.

Cons

- Mono stinger staircases need a customized, engineered stringer that is not readily available like pre-cut closed stair stingers.

- Because both the treads and stringer are likely to be a custom design, this staircase design is typically more expensive.

- Mono stringer stair cases are not normally used for long distances.

Twin stringer

A variation of the mono stair stringer is a twin stringer. In this case, two thin stringers take the place of the mono stringer. They are usually placed about 6” apart in the middle of the stairs. They can also be placed off center to create a more striking look.

Twin stair stringer applications

Like mono stair stringers, twin stair stringers are mostly used in contemporary residences and offices to achieve an open, modern look.

Twin stair stringer advantages & disadvantages

Pros

- The stringers tend to be more hidden behind the stair treads than with a mono stringer design.

Cons

- As with mono stringer stairs, twin stingers are not usually used for long distances because the stairs can twist.

Cantilevered stringer

A staircase with a cantilevered stringer features a single side stringer which is in mounted inside a wall and reinforced. The treads, which are supported by the stinger, protrude from the wall and the staircase is normally open on the other side.

Cantilevered stair stringer applications

Cantilevered stair stringers are used in homes and offices to achieve a stunning architectural effect.

Cantilevered stair stringer advantages & disadvantages

Pros

- With their floating appearance, cantilever stairs create a more open and spacious appearance to the room.

- Floating stairs with cantilevered stair stringers provide one of the most modern, unique and visually interesting looks.

- Because the stair stringer is installed in the wall, cantilever stairs can provide more headroom.

Cons

- With cantilever staircases, the design of the support structure needs to be taken into consideration and installed into the wall before it is complete.

- Due to the additional structural requirements, cantilever stairs can be more expensive to build than other types of staircases.

- If not properly reinforced, the treads of cantilevered steps may sag on the open side.

- Often, cantilever stairs do not have a railing to reinforce the floating effect, which can also make them more dangerous.

Final points on the different kinds of stair stringers

Staircase stringers are the part of the stair which provides support for and houses the treads and risers. The type of materials used for the stringers, as well as the style of the stringers, will affect the look of the staircase. A staircase with a closed stair stringer made of steel or wood may be utilized more for function that style. Other types of stair stringers such as open, mono and cantilever provide the opportunity for more dramatic and contemporary looks.

FAQs

How many stringers are needed for stairs?

At least one stringer is needed for a stair designed with a center or mono stringer underneath the stair treads. Two stringers are used with a double or twin stringers positioned to the outside of the stair treads.

Do stair stringers need support?

Stair stringers may need additional support depending on the length of the stair stringer and the width of the staircase. Wood stair stringers typically need additional supports between 6′ and 10′ lengths while metal stair stringers typically do not require additional supports.

What is the maximum stair stringer length?

The maximum stair stringer length depends on the material used for stringer construction, the stringer size, and the stair building code requirements. IBC stair code limits stair stringers to a maximum vertical height of 12′ in a single run.

Can you build stairs without stringers?

You can build stairs without stringers if each stair tread provides it own structural support by constructing them as boxes or adding supports for each tread. Building stairs this way might be less economical than using stair stringers.