When designing or building a staircase, it’s important to consider not only the type of staircase, but also the type of stair treads and stair tread nosing. Whether the staircase is part of new construction or a remodel, the kind of stair treads and nosing selected will impact the look of the staircase and can also affect the overall safety of travelling up and down the staircase. Below are some factors to consider when deciding on these components.

How many types of stair treads are there?

The stair tread is the horizontal part of a staircase that you step on when climbing up or down the stairs. Of all the staircase parts, treads are typically the largest visible component. So, the kind of stair tread you choose will have a big impact on the overall look of the staircase. Stair treads are available in a variety of materials, styles and finishes that can contribute to the interior design of the staircase and space.

What is the best material for stair treads?

The best material for stair treads depends on many factors. Some materials are more suited for indoor use, while other more durable materials may be used outside. Different types of staircases may utilize different types of stair treads. Whether the stair case is in an industrial, commercial or residential setting can also impact the type of stair tread material. Some tread systems work better for bolted steel stairs while others fit a

Steel

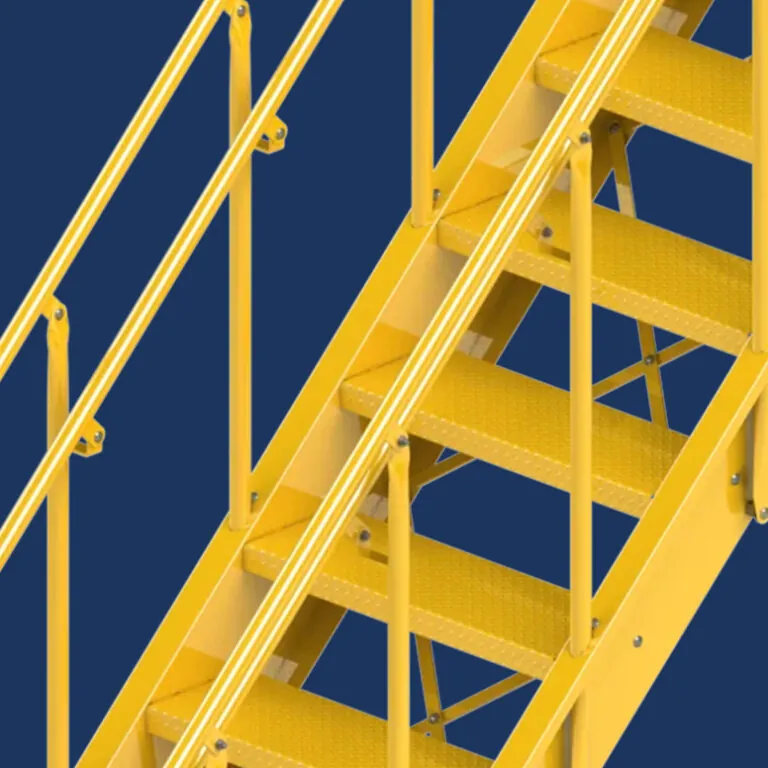

Steel is an alloy made up of iron, carbon and other materials. The steel used in staircases can be primed and painted to match the design of the building; have a powder coat finish; or be galvanized with a long-lasting zinc coating that prevents corrosive substances from reaching the steel below. Steel treads are extremely durable and fire resistant making them a long-term, safe material for many applications.

Steel stair tread types and applications

Steel stair treads are often used in industrial and outdoor applications. Steel or metal stair treads with a diamond pattern, bar grating surface, or an

abrasive coating can be used in commercial building interiors and exterior applications, such as apartment buildings and parking garages. Steel stair treads are also used in private homes and are commonly found on spiral staircases.

Steel stair tread advantages & disadvantages

Pros

- Steel treads are very strong and are able to bear excessive weight and extreme environmental conditions.

- Staircases with steel treads are extremely durable. They resist corrosion, rot and damage from pests.

- Steel is versatile and can be fabricated into different shapes and patterns to form treads for a traditional staircase or a unique or customized staircase.

- As compared to other materials like concrete and wood, steel is a very economical choice for stair treads.

Cons

- The main drawback of steel treads is that they can be slippery, especially when wet. Some sort of slip protection, like diamond plating or an abrasive coating, should be used.

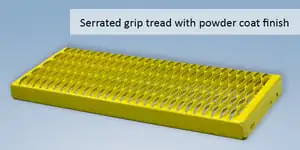

- For outdoor applications, bar grate or serrated treads are an ideal choice.

Aluminum

Aluminum is a silvery-white metal — the thirteenth element in the periodic table. Aluminum is the most wide spread metal on earth making up more than 8% of the earth’s core mass. Aluminum is naturally corrosion resistant without any further treatment. Aluminum is also lightweight, weighing more than 50% less than steel for the same volume.

Aluminum stair tread applications

Like steel treads, aluminum treads are used in a variety of industrial, commercial and residential applications. Aluminum treads can be found in fire escapes, stairs for machinery and mezzanine access, and residential garden or deck stairs. Because of its light weight and corrosion resistance, aluminum is the preferred material for roof stairs, ship stairs on boats, other marine applications, and chemical environments. Aluminum treads are frequently cast into shape.

Aluminum stair tread advantages & disadvantages

Pros

- Aluminum is durable and can last for more than 30 years.

- Since aluminum treads are more than 50% lighter than steel treads, they can be a good option when weight is a factor, such as with roof stairs or stairs that need to be repositioned from time to time.

- Because of its antibiotic properties, aluminum might be preferred for treads in some environments, such as food processing.

Cons

- Aluminum treads are generally more expensive than steel treads.

- While durable, aluminum treads are not as weather resistant as steel treads with galvanized coating.

- Aluminum treads are more prone to scratches and dents than steel treads.

Stainless steel

Stainless steel treads are the Cadillac of stair treads. Stainless steel is a type of steel alloy with chromium and / or nickel added to help prevent corrosion and rusting, and add heat resistance to the material. Because of these properties, stainless steel is used in high-heat environments like cooking equipment. Stainless is also more easily cleaned than other metals and is a great material for food applications.

Stainless steel stair tread applications

Stainless steel stair treads are a high-performance tread material and considerably more expensive than other metals. Because of the cost, they are best for specialized applications like food production, cooking, chemical applications and other high-heat, corrosive environments.

Pros

- Corrosion and rust resistant

- Heat resistant

- Easier to clean than carbon steel

Cons

- Very expensive compared to carbon steel

- Heavier than carbon steel and aluminum

Concrete

Concrete is comprised of three components: water, aggregate (rock, san, or gravel) and powdered cement. The cement acts as a binding agent when mixed with water and aggregates, which when poured will harden into concrete.

Concrete stair tread applications

Concrete is the most popular material used to build outdoor stairs due to its durability, but can also be used as the base of stairs in offices and homes that are then covered with other materials. Metal pan stair treads with poured concrete are very popular for commercial egress stairs. Pre-cast concrete stair treads are popular for apartments and residential outdoor and indoor stairways.

Concrete stair tread advantages & disadvantages

Pros

- Concrete stair treads are long lasing and require little maintenance.

- Because concrete can be easily shaped, you can build concrete stairs in a variety of styles from straight to curved or spiral.

Cons

- Can be messy and costly to install since every individual tread must be poured in place.

- The main disadvantage of concrete treads is that they look dull and ordinary. However, they can be covered with premium materials such as stone or tile to create a luxurious look.

- Especially when used outdoors, concrete may also crack over time but use of a sealer can help to protect the treads.

Wood

Many different types of wood can be used for staircase treads. The most important consideration is if the stairs will be for interior or exterior use, as many types of wood are not durable when exposed to the outdoor elements.

Many wood species can be used for interior stair treads including red oak, cherry, maple, walnut and engineered wood. Each will provide a different type of visual appeal. For exterior wooden staircases, ironwoods should be used for treads due to their hardness. However, cedar and redwood can also be used outside as they are more weather resistant than other types of wood.

Wooden stair tread applications

Although wood is not a popular tread material for industrial applications or tall commercial buildings, it is the most common tread material used in private residences.

Wooden stair tread advantages & disadvantages

Pros

- Wood is one of the most affordable types of tread material.

- Despite its affordability, a staircase with wood treads can add value and elegance to a home due to its natural beauty.

- Wood is thought to be one of the safest materials for stair treads and provides homeowners more security when children or older people reside in the house.

Cons

- Wood stairs needs to be stained to prevent damage to them.

- Outdoor wood treads especially need regular care or they will turn gray due to continued exposure to the elements and also need to be treated for pests.

- Wood treads can be damaged extreme temperatures and high humidity.

Glass

In recent years, glass has become a popular material for stair treads. Many colors, patterns, textures and finishes are available to provide a unique look for your staircase.

Glass stair tread applications

While you’re not likely to find glass stairs in an industrial setting, many modern residences and commercial buildings use glass tread staircases to create a modern and open look.

Glass stair tread advantages & disadvantages

Pros

- Glass treads can be used to make a striking architectural statement and give the interior a more spacious look.

- Light can pass through glass treads making the staircase more appealing during the day. LED lights can also be added to provide a dramatic lighting effect.

- Glass treads do not deteriorate over time like wood treads do and are not as expensive to maintain.

- Glass treads are water resistant and will not rot over time like wood treads.

Cons

- Treads made of normal or poor-quality glass can break or shatter. However, treads made of fabricated glass are stronger and can stand up to a large amount of weight.

- Even with fabricated glass, accidents can still happen through spills or dropping heavy objects. Glass treads should be checked regularly for hidden cracks.

- Because they are difficult to install, staircases with glass treads are much more expensive than stairs with wood or concrete treads.

- While not expensive to maintain, glass treads require frequent cleaning to ensure a clean appearance.

Tile

With a variety of design options, tile stair treads can be a beautiful alternative to other materials. Tile is composed of naturally occurring materials with many options that are made from recycled materials.

Tile stair tread applications

Like glass, tile treads are mostly found in commercial buildings and private homes. Tile is often used for staircases located in an entryway to make a bold statement.

Tile stair tread advantages & disadvantages

Pros

- Tile is a highly durable material that can withstand high traffic due to its scratch-, stain- and fire-resistant qualities.

- Tile treads are easy to maintain as they are water-resistant and not susceptible to rotting or insects.

- Tile treads are generally affordable and less expensive than hardwood.

Cons

- Tile treads do not absorb or hold heat, so they tend to be quite cold in the winter time.

- Tile can be slippery so it’s important to keep the treads dry.

Stone

Stone stair treads come in a variety of options. The most popular type of stone tread is bluestone, which is a bluish sliver color. Limestone, which is an off-white color, is also commonly used.

Stone stair tread applications

Stone stairs are most often used in outdoor applications such as gardens but can also be used in homes, offices and commercial buildings. They are typically not found in industrial settings.

Stone stair tread advantages & disadvantages

Pros

- Stone stair treads are extremely durable and can literally last for thousands of years.

- They require little to no maintenance.

- If used outside, stone treads compliment the natural adjacent landscape.

- Unlike other materials, stones may be more suitable for constructing stairs in a hilly and rough terrain.

Cons

- Because of their heavy weight, some stones may require small tractors to install.

- If the stone treads have an uneven surface, they may pose more of a tripping hazard than other types of treads.

What are the different types of stair treads?

As we’ve discussed, stair treads can be made from a variety of materials. But there are also several different types of stair treads.

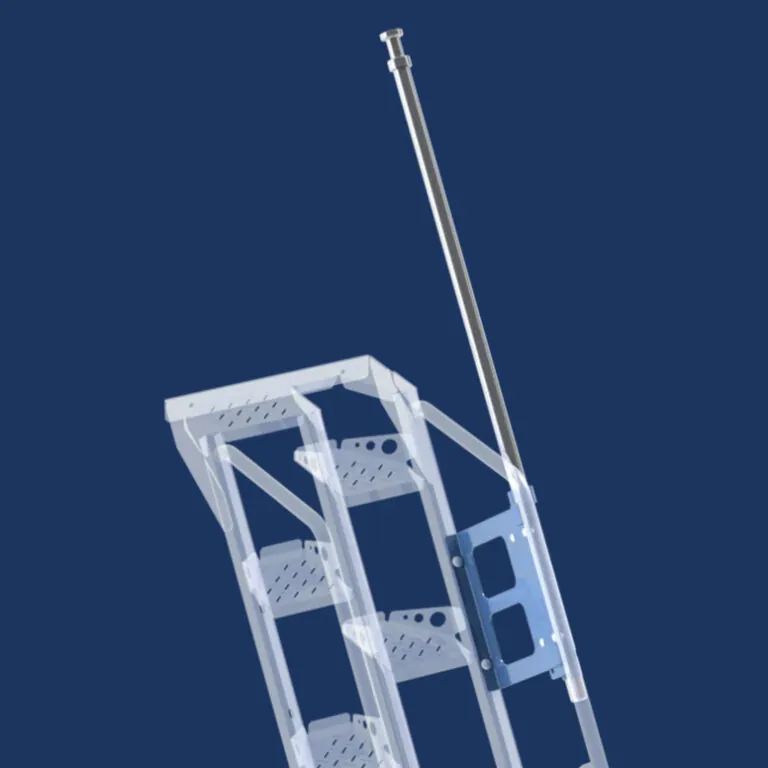

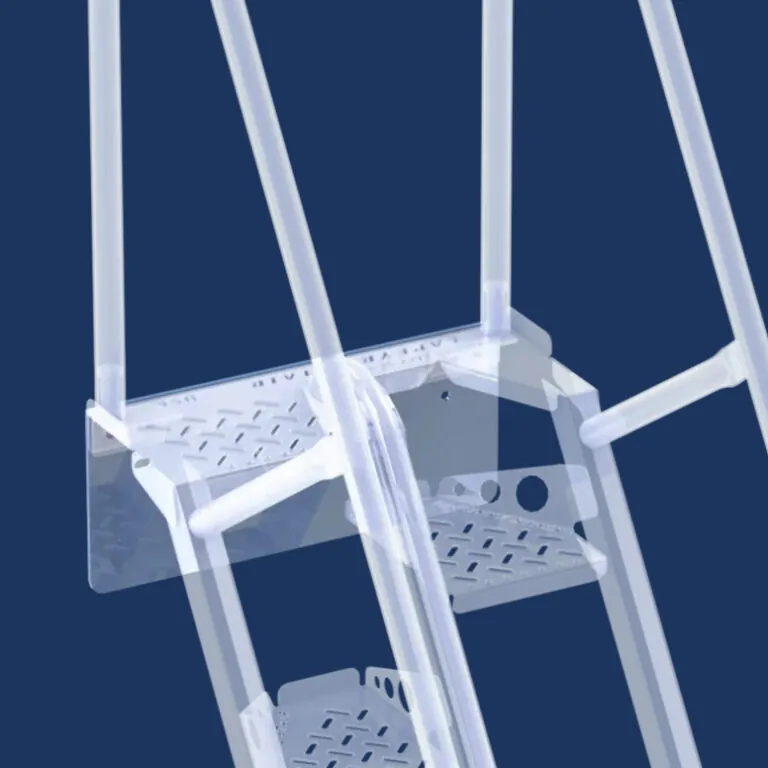

Alternating stair treads

With standard stairs, each foot normally uses only about half of each tread, stepping out and over the unused section. With alternating tread stairs, the unused half tread is removed to provide more stair tread depth.

Alternating tread stairs provide additional safety and comfort to the user. Typically, the user faces the direction of travel when climbing up and down the stairs. The stair slope requires a smaller overall footprint than a standard stair.

Because of the unusual design and steepness, it can take practice to learn how to climb alternating tread stairs. Alternating tread stairs are not intended for use as a main staircase, but are only suitable for access to a single room such as an attic, cellar, roof or mezzanine.

Alternating stair tread applications

These space saving stairs are commonly seen in residential, industrial and commercial applications. They can provide a convenient way of reaching an attic, basement, mezzanine or other space where a standard staircase wouldn’t fit.

Non slip stair treads outdoor

Non slip stair treads outdoor

Non slip stair treads are commonly used on outdoor stairs to increase traction and reduce the potential for accidents. Typically, the treads are covered with a light-weight, bolt-on tread cover which features a permanent, abrasive polyurethane coating.

However, there are other types of outdoor non slip stair treads. Diamond plate treads feature a pattern of raised diamond on one side with the reverse side being smooth. Bar grating treads feature an open grid assembly of metal bars. Grip treads feature a serrated surface which help reduce accidents by providing a safer walking and working surface.

Non slip stair tread applications

Non slip stair treads are commonly found in industrial environments, as well as outdoor metal stairs in high traffic areas of commercial settings.

Concrete filled metal pan stair tread

A concrete filled metal pan stair tread consists of a metal pan which is filled with concrete. Typically, 1.5″ of concrete is poured into each stair pan individually. The steel pan treads are fabricated and attached to the stair stringers. Metal pan stairs can work with various types of stair stringers. The concrete is poured into the metal pan to establish the walking surface of the stair tread.

Concrete filled metal pan stairs are durable and require low maintenance. However, they are costly, time consuming, and can result in safety hazards during construction.

Concrete filled metal pan stair tread applications

Concrete filled metal pan stairs are a tread system commonly used in steel stairs for commercial and residential buildings.

What are the types of stair nosing details and design?

Stair nosing is the front of the tread which protrudes beyond the riser. Some staircases do not have nosing but some building codes make it mandatory. Stair nosing is available in a variety of materials including rubber, aluminum and wood. There are also several different types of stair nosing.

Stair nosing details

Anti-slip contrast nosing

Anti-slip contrast nosing

Because this is where most of the foot traffic occurs, anti-slip strips may be applied to the nosing to make navigating the stairs easier. The addition of nosing in a contrasting color provides an extra measure of safety by helping users visually identify the presence of a step edge.

Photo-luminescent (glow-in-the-dark) nosing

Photo-luminescent glow nosing is used in high-rise buildings for egress stair applications. The glow in the dark strips help users identify the edge of each stair tread in the case of emergency or power outage.

Metal pan nosing

Metal pan nosing

Metal pan stair treads have a lip that turns up to contain the poured concrete. This style of nosing is very popular for commercial egress stairs.

Cast abrasive nosing

Cast abrasive nosing

Abrasive nosing cast into concrete treads is a great solution for outdoor stair treads that need better slip resistance than what the concrete alone provides. An abrasive nosing is very popular for outdoor egress stairs.

Stair nosing designs

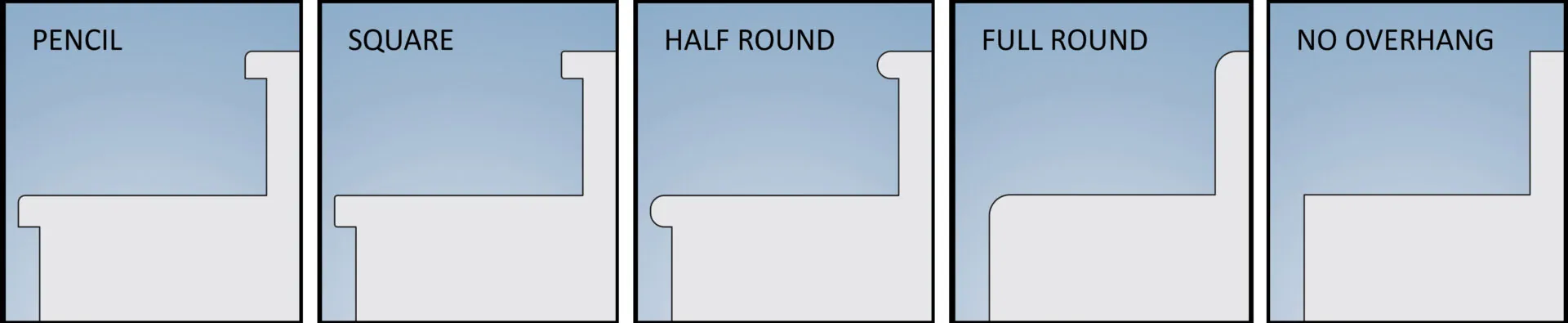

Pencil style nosing

This popular stair nosing design has rounded edges which look like a pencil which has been turned sideways. Pencil nosing is a common option for traditional staircases but can be used with modern styles as well. Pencil nosing has no sharp edges and creates a streamlined look down the length of the staircase.

Square style nosing

Even though this stair nosing detail is named square, it usually has slightly rounded edges. Not only do the rounded edges ensure the stairs are not too sharp, they also protect against nicks and dents. Square nosing is a popular for both modern and contemporary stairs.

Half-round style nosing

This stair nosing profile has two partially rounded edges with a flat surface between. This type of nosing looks like a half moon and is also referred to as bullnose.

Full round style nosing

Full round nosing features a continuous curve on the front edge of the stair to provide a smooth look and feel. Because this type of nosing provides less slip protection is often used for only the landing step or on grand staircases.

No overhang style nosing

Unlike other stair nosing types, no overhang nosing sits flush with the riser below, giving the appearance of no nosing at all. This creates a sleek look and it commonly used for classic and contemporary staircases. No overhang nosing reduces the chances of tripping but also slightly reduces the size of your stair tread due to the loss of the nosing projection.

Our conclusion on the different nosing & stair treads types

Two important components of staircase design are the stair treads and stair tread nosing. Stair treads can be made from a variety of materials including steel, aluminum, concrete, wood, glass and tile. The pros and cons should be considered when selecting a tread material, as well as the type of tread to use. Nosing styles can affect both the appearance and safety of the staircase, so the nosing design should be carefully considered as well.