Industrial environments present unique challenges when it comes to ensuring the safety and efficiency of workers navigating through various levels of a facility. Among the critical elements of industrial staircases, which provide access to elevated areas and serve as essential pathways for daily operations. Whether it’s a metal stairway, crossover stairs, or loading dock stairs, adhering to specific requirements is paramount to mitigate risks and maintain compliance with safety regulations. In this comprehensive guide, we’ll delve into the essential industrial stair requirements, exploring key considerations and best practices to uphold safety standards in industrial settings.

Understanding Industrial Stair Requirements

Compliance with Building Codes and Standards

Industrial staircases must meet stringent requirements set forth by building codes and safety standards. These regulations are established to ensure the structural integrity, stability, and safety of stair systems. Commonly referenced codes include Occupational Safety and Health Administration (OSHA) standards and the International Building Code (IBC), when industrial stairs are part of the building’s structure. Compliance with these regulations is non-negotiable and forms the foundation of a safe industrial stairway design.

Structural Integrity and Load-Bearing Capacity

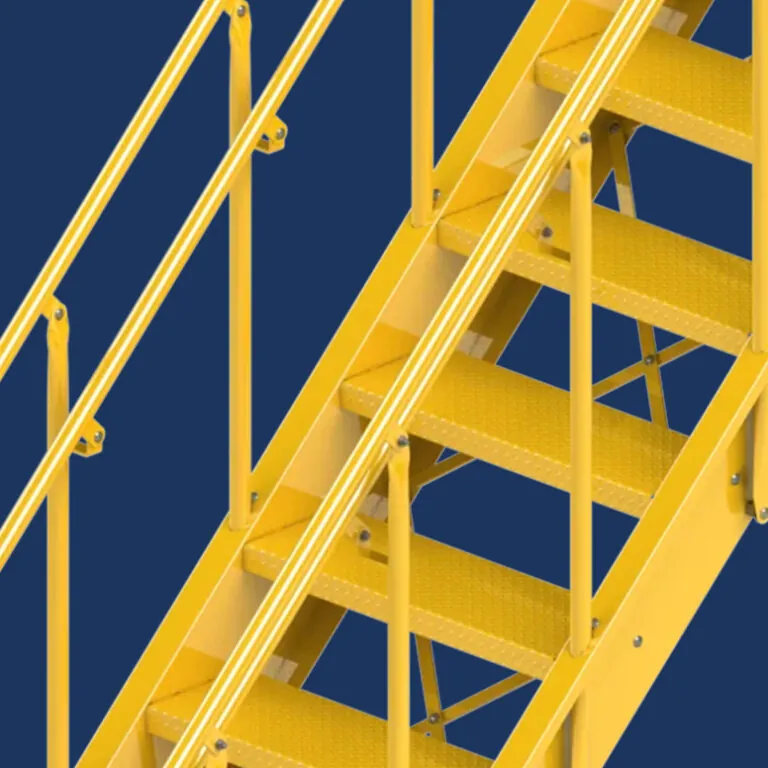

Metal industrial staircases must be structurally sound and capable of supporting anticipated loads. Factors such as material strength, construction methods, and support mechanisms play a crucial role in determining the structural integrity of stair systems. Load-bearing calculations should be performed to ensure that the stairs can withstand the weight of personnel, equipment, and materials without compromising safety.

Dimensions and Clearances

Proper dimensions and clearances are essential for ensuring safe passage on industrial staircases. The width of stair treads, the height of risers, and the depth of treads must conform to established standards to prevent tripping hazards and ensure ergonomic usability. Additionally, adequate headroom clearance should be maintained to accommodate individuals of varying heights and prevent head injuries.

Handrails and Guardrails

Handrails and guardrails are integral components of industrial staircases, providing support and fall protection for users. According to OSHA regulations, handrails are required on stairways with four or more risers. Additionally, guardrails are necessary along open sides of stairs exceeding 30 inches in height. These safety features must be securely installed and meet specific height and strength requirements to effectively prevent falls and injuries.

Traction and Slip Resistance

Slip and fall accidents are prevalent in industrial environments, making traction and slip resistance critical considerations for industrial staircases. Stair treads should be designed with non-slip surfaces or equipped with anti-slip coatings to enhance grip and reduce the risk of slips and falls. Slip resistance is especially important in areas prone to moisture, grease, or other contaminants.

Ergonomics

Consideration should be given to the ergonomic design of stairs to minimize fatigue and strain on workers during ascent and descent. Non-standard stairs, such as alternating tread stairs, can considerably increase use safety and comfort, especially in space restricted areas.

Types of Industrial Staircases

Metal Stairways

Metal stairways are popular choices for industrial settings due to their durability, strength, and versatility. Whether constructed from galvanized steel, stainless steel or aluminum, metal stair systems offer excellent load-bearing capacity and long-term performance. Metal stairways can be customized to suit specific requirements, making them ideal for a wide range of industrial applications.

Mezzanine Stairs

Mezzanine stairs combine the functionality of stairs with elevated platforms, offering seamless access to different levels within a facility. These integrated systems provide safe and efficient pathways for workers while maximizing usable space. Mezzanine stairs can be customized with various configurations, handrail options, and safety features to meet specific application requirements.

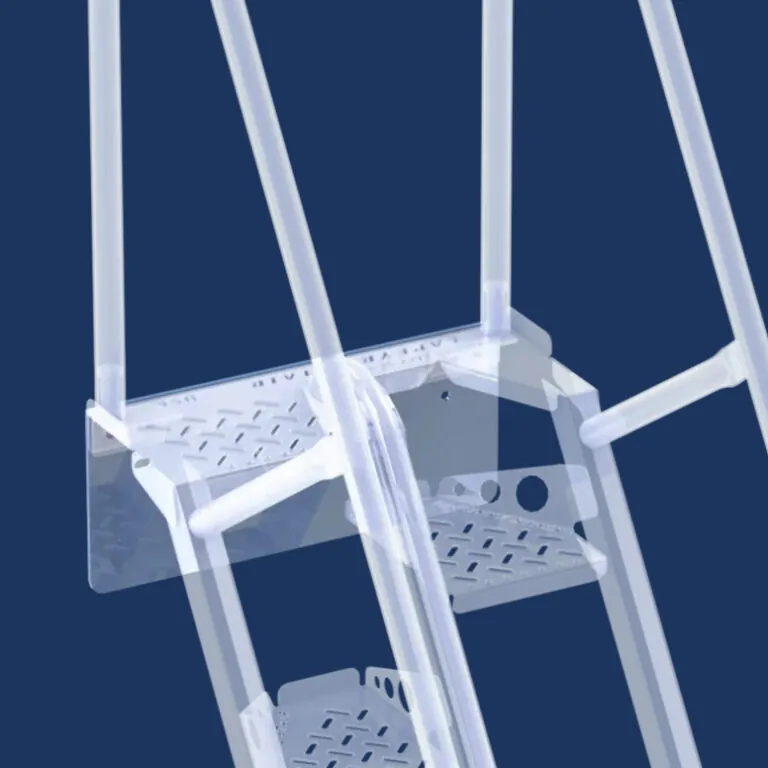

Loading Dock Stairs

Loading dock stairs create a critical throughway for the movement of employees and goods. These stair systems ensure workers and suppliers have safe and convenient access to your facility. Loading dock stairs can be configured in different widths and with a variety of materials, treads and platform options.

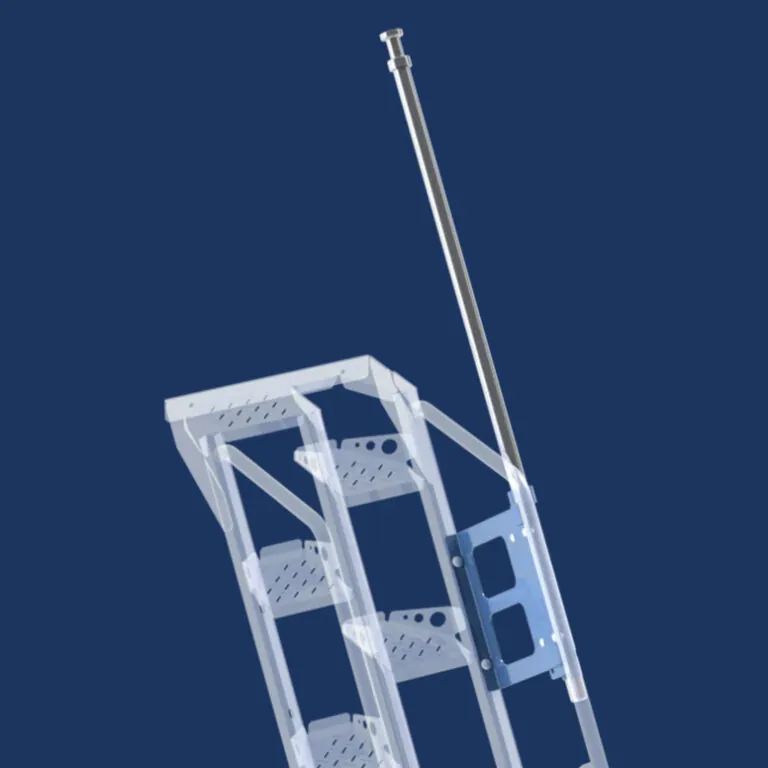

Stair Towers

Safe access to rooftops and structures can be provided with a stair tower when a traditional stair system cannot be supported. Stair towers can be completely free-standing or integrated into existing structures.

Custom Staircases

Custom staircases are tailored solutions designed to meet the unique needs and specifications of industrial environments. These solutions offer flexibility in layout, materials, and finishes to accommodate site-specific challenges and architectural requirements. Custom staircases allow for unique design challenges while prioritizing safety and functionality in industrial settings.

Conclusion: Prioritizing Safety in Industrial Stair Design

Industrial staircases are more than mere pathways; they are vital components of workplace safety and efficiency. By adhering to essential requirements and standards, industrial facilities can create stair systems that promote safe movement, enhance productivity, and comply with regulatory mandates. Prioritizing safety in industrial stair design is essential to protect the well-being of workers and mitigate the risk of accidents and injuries in industrial environments.