Ensuring compliance with Occupational Safety and Health Administration (OSHA) standards is paramount for any industrial facility aiming to maintain a compliant and safe working environment. Among the elements that fall under OSHA regulations, industrial stairs and platforms play a crucial role in providing safe access to elevated areas and work spaces. However, not all compliance standards are equal in terms of their importance and impact on workplace safety. In this comprehensive guide, we’ll rank OSHA compliance standards for industrial stairs and platforms by their importance, highlighting key considerations for each.

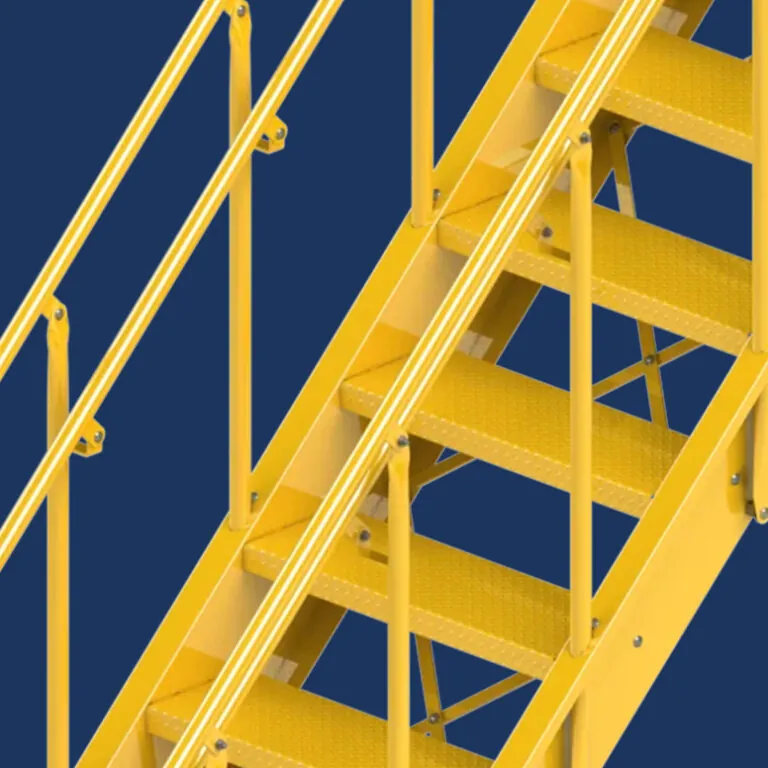

1. Guardrail and Handrail Requirements

Ranking first in importance is compliance with OSHA’s guardrail and handrail requirements. According to OSHA regulations (29 CFR 1910.23), industrial stairs must be equipped with guardrails along open sides to prevent falls. Additionally, handrails are also mandated to provide additional support and stability for workers navigating stairs. Ensuring the proper installation, height, and strength of guardrails and handrails is essential for preventing accidents and injuries related to falls from heights.

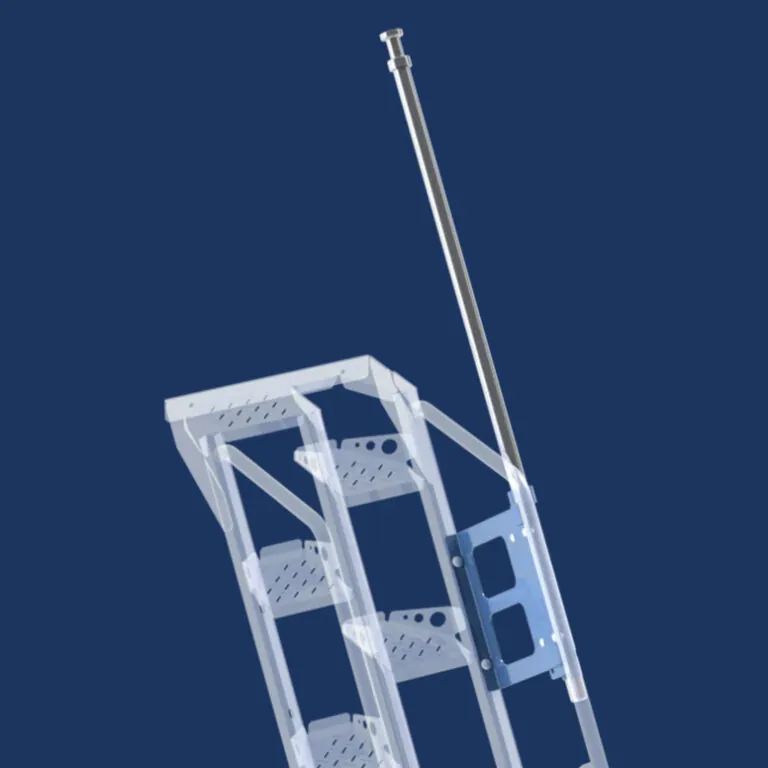

2. Load-Bearing Capacity and Structural Integrity

Next on the list is compliance with OSHA standards regarding the load-bearing capacity and structural integrity of industrial stairs and platforms. Stair systems must be designed and constructed to withstand anticipated loads, including the weight of workers, equipment, and materials. OSHA regulations require periodic inspections and maintenance to ensure that stairs remain structurally sound over time. Failure to comply with load-bearing requirements can lead to structural failures and catastrophic accidents.

3. Tread and Riser Dimensions

Ranking third in importance is adherence to OSHA’s specifications regarding tread and riser dimensions for industrial stairs. OSHA regulations specify minimum and maximum dimensions for tread width, riser height, and stair slope to ensure safe and ergonomic stair design. Proper tread and riser dimensions help prevent tripping hazards, minimize fatigue, and promote comfortable stair use for workers. Compliance with these standards is crucial for reducing the risk of slips, trips, and falls on stairs.

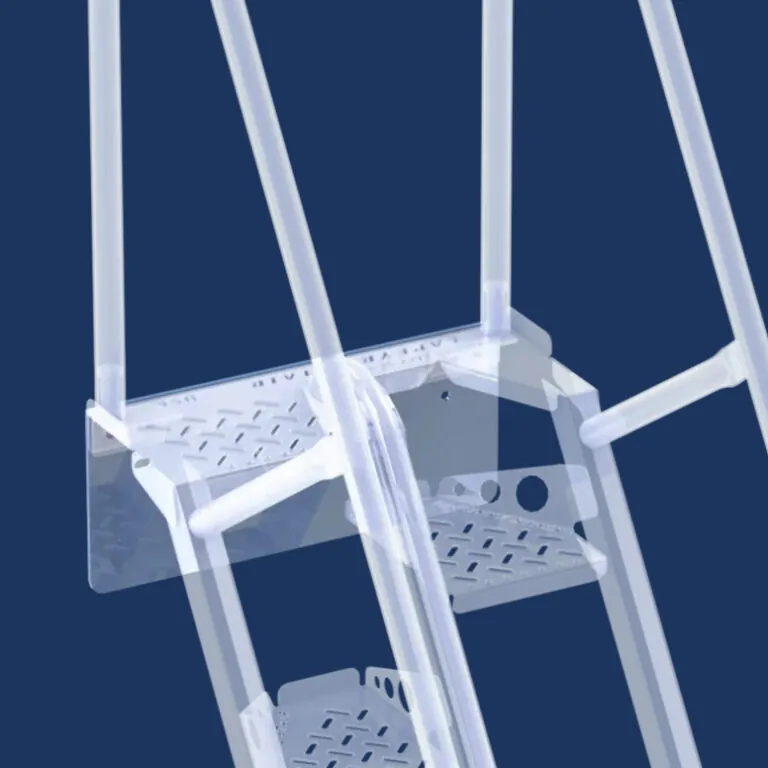

4. Slip Resistance and Traction

Ensuring slip resistance and traction on industrial stairs and platforms is another key aspect of OSHA compliance. OSHA regulations require stair treads to be designed with slip-resistant surfaces or equipped with anti-slip materials to reduce the risk of accidents. Installing abrasive strips or coatings, can help prevent slips and falls, especially in areas prone to moisture or contaminants.

5. Clearances and Headroom

Compliance with OSHA standards regarding clearances and headroom is also essential for industrial stairs and platforms. OSHA regulations specify minimum clearances for stairways to prevent obstructions and ensure unimpeded passage. In addition, adequate headroom clearance is important to prevent head injuries and provide sufficient space for workers to navigate stairs comfortably. Failure to comply with clearances and headroom requirements can result in safety hazards and regulatory violations.

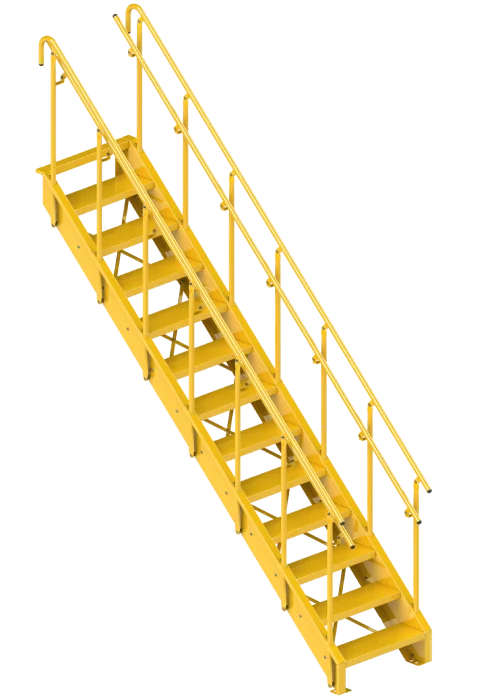

6. Platform and Landing Requirements

Compliance with OSHA’s platform and landing requirements rounds out the list of important standards for industrial stairs and platforms. OSHA regulations mandate the provision of platforms or landings at the top and bottom of stairways to facilitate safe entry and exit. Platforms must be of sufficient size to accommodate workers and equipment, with guardrails and handrails provided as necessary. Ensuring compliance with platform and landing requirements is critical for preventing falls and providing safe access to elevated areas.

Conclusion: Prioritizing OSHA Compliance for Industrial Stairs & Platforms

In the realm of industrial safety, compliance with OSHA standards for industrial stairs and platforms is of paramount importance. By ranking OSHA compliance standards by their relative importance, industrial facilities can prioritize efforts to address the most critical safety considerations. From guardrail and handrail requirements to load-bearing capacity and slip resistance, each compliance standard plays a vital role in mitigating risks and ensuring the safety of workers navigating stairs and platforms in industrial environments. By prioritizing OSHA compliance, industrial facilities can create safer workplaces and reduce the likelihood of accidents and injuries associated with industrial stairs and platforms.