Improperly maintained and used walking and workings surfaces are the number 1 source for falls, slips, and trip hazards in the workplace. To reduce the chance of incidences, employers in general industry must ensure that all OSHA walking working surfaces requirements per section CFR 1910 Subpart D are met and adhered to by employees. Employers must also make sure that employees are trained and outfitted with the proper safety equipment under the walking surface requirements.

Walking working surfaces assessment inspection, training, fact sheet & quiz

The osha walking working surfaces regulations underwent a major update in 2017 to improve the safety of stairs, ladders, and walkways. The new OSHA standards under the final rule affect all employers in general industry workplaces. Performing an inspection assessment of your walking surfaces can help prevent slips, trips, and falls by ensuring compliance with the new requirements . This guide will help you with perform a walking working surfaces assessment for your facility to identify hazards and comply with the OSHA requirements.

OSHA walking and working surfaces checklist

To identify work area hazards and requirements, it helps to start by defining a hazard. A hazard is the potential for harm that can result in an injury or illness. The OSHA regulations are in place to identify and prevent hazards to improve walking working surfaces safety. For example, the OSHA trip hazard definition is a type of hazard caused by an abrupt change in vertical elevation or horizontal separation on any walking surface along the normal path of travel. By identifying these types of hazards and eliminating them, trips can be prevented in the workplace.

To identify work area hazards and requirements, it helps to start by defining a hazard. A hazard is the potential for harm that can result in an injury or illness. The OSHA regulations are in place to identify and prevent hazards to improve walking working surfaces safety. For example, the OSHA trip hazard definition is a type of hazard caused by an abrupt change in vertical elevation or horizontal separation on any walking surface along the normal path of travel. By identifying these types of hazards and eliminating them, trips can be prevented in the workplace.

An OSHA walking and working surfaces checklist can help you identify and eliminate hazards from the workplace and prevent incidences like falling down stairs. This inspection checklist lists all the potentially hazardous areas of a workplace and the OSHA requirements for each. It includes the requirements for stairways, ladders, walkways, elevated platforms, floor and wall openings, catwalks, and loading docks along with the fall protection requirements for each. Implementing this inspection process along with an effective training program is a great start for any safety program.

Free Download: OSHA walking and working surface checklist

General requirements for walking working surfaces checlist

| OSHA Section | What to check |

| 1910.22(a)(2) | Are all places of employment, passageways, storerooms, service rooms, and walking-working surfaces kept in a clean, orderly, and sanitary condition? |

| 1910.22(d)(1) | Are wet surfaces covered with non-slip materials? |

| 1910.22(a)(3) | Are walking-working surfaces maintained free of hazards such as sharp or protruding objects, loose boards, corrosion, leaks, spills, snow, and ice. |

| 1910.22(b) | Are walking-working surfaces designed to meet the maximum intended loads? The employer must ensure that each walking-working surface has the structural integrity to support the maximum intended load for that surface. |

| 1910.22(c) | Access and egress. Are employees provided with a safe means of access and egress to and from walking-working surfaces? |

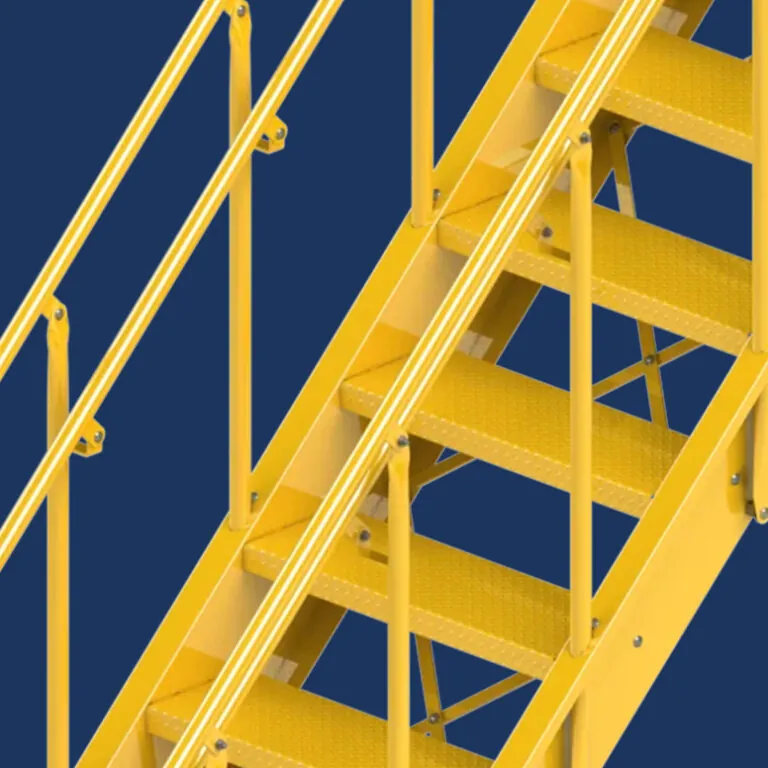

Stairways checklist

| Section | What to check |

| 1920.25(b)(1) | Is there a guardrail and handrail on all stairs with four or more risers? Every flight of stairs with four or more risers must have a stair rail. |

| 1910.29(f)(1)(i) | Are stair rails equipped with handrails between 30 and 38 inches above the leading edge of the stair treads? |

| 1910.29(f)(1)(ii)(A) | Are stair guardrail heights above the leading edge of the stair tread at least at least 30 inches (if installed before 10/1/20) or 42 inches (if installed after 10/1/20)? |

| 1910.25(c)(4) | Are all stairways at least 22 inches wide? |

| 1920.25 (b)(2) | OSHA headroom clearance. Is there adequate vertical headroom clearance above any stair tread to any overhead obstruction at least 6 feet, 8 inches (203 cm) |

| 1910.25(b) | Are stair landings and platforms at least the width of the stair and at least 30 inches deep? |

| 1910.25(c) | Do stairs have minimum tread depth and maximum riser heights of 9.5” and max angle of 45 degrees? |

| 1910.25(b)(3) | Are treads and risers uniform in size? |

| 1910.25(b)(6) | Can each stair support at least five times the anticipated live load and a concentrated load of 1,000lbs? |

| 1920.25(b)(7) | When feasible, are standard stairs provided and for operations that require routine and regular travel between levels, including access to operating platforms and equipment? |

| 1910.25(b)(8) | Are ship stairs, spiral stairs, or alternating tread stairs used for tight space applications? |

| 1910.28(b)(11)(iii) | Are ship stairs and alternating tread stairs equipped with a 30” to 38” high handrail on both sides? |

| 1910.25(f)(3)

1910.25(e)(3) |

Do alternating tread stairs have a minimum 8.5″ tread surface and ship stairs have a minimum 4″ tread surface? |

| 1910.22(d)(1) | Are step surfaces slip resistant? |

| 1910.178(m)(14) | Where stairs exit directly into an area where vehicles may be operated, are adequate barriers and warnings provided to prevent employees from stepping into traffic? |

| Resource: OSHA walking working surfaces checklist pdf |

Walkways and aisles checklist

| Section | What to check |

| 1910.176(a) | Are aisles and walkways kept clear, free of trip hazards, and marked as appropriate? |

| 1910.22(a)(2) | Are wet surfaces covered with non-slip materials? |

| 1910.22(d)(2) | Are holes in the floor, sidewalk, or other walking surface repaired properly, covered, or otherwise made safe? |

| 1910.176(a) | Is there safe clearance for walking in aisles where motorized or mechanical handling equipment is operating? |

| 1910.22(a)(3) | Are materials or equipment stored in such a way that sharp projections will not interfere with the walkway? |

| 1910.22(a)(2)

1910.22(a)(3) |

Are spilled materials cleaned up immediately? |

| Are changes of direction or elevations readily identifiable? | |

| 1910.22(a)(3)

1910.176(a) |

Are aisles or walkways that pass near moving or operating machinery, welding operations, or similar operations arranged so employees will not be subjected to potential hazards? |

| 1910.25(b)(2) | Is adequate headroom of 80” provided for the entire length of any aisle or walkway? |

| 1910.28(b)(1)(i) | Are standard guardrails provided wherever aisle or walkway surfaces are elevated more than 48 inches above any adjacent floor or the ground? |

| 1910.22(c) | Are bridges provided over conveyors and similar hazards? |

| 1910.22(c)

1910.25(b)(7) |

Are conveyor crossovers provided with standard stairs, alternating tread stairs, or ship stairs for safe access and egress? |

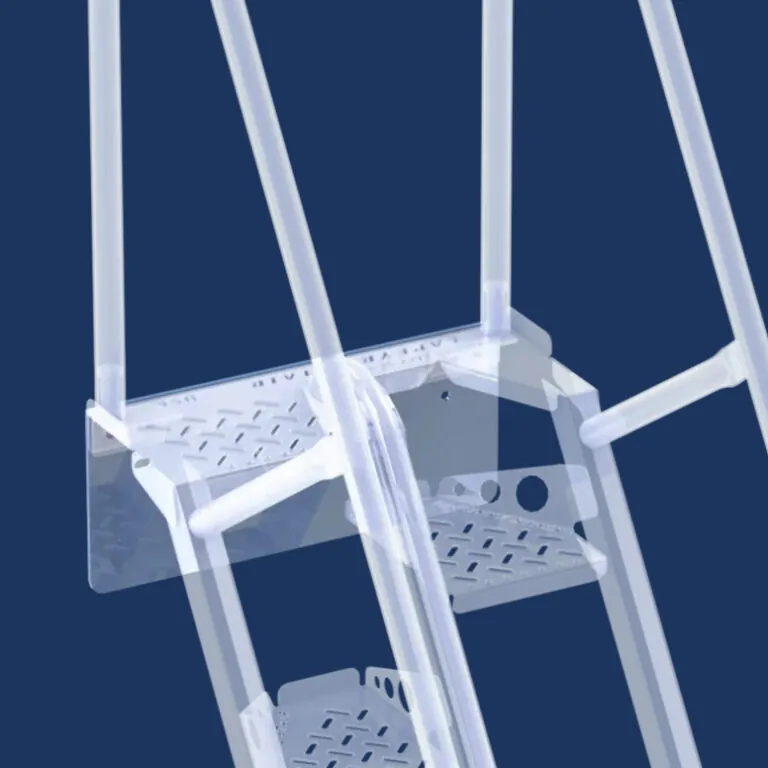

Elevated platforms and catwalks checklist

| Section | What to check |

| 1910.28(b)(5)(ii)(A) | Is the platform width at least as wide as the stair width and / or minimum of 18”? |

| 1910.22(c) | Is a permanent means of access provided to elevated work surfaces? |

| 1910.22(a)(1)

1910.176(b) |

Is material on elevated surfaces piled, stacked, or racked in a manner to prevent it from tipping, falling, collapsing, rolling, or spreading? |

| 1910.28(b)(1)(i)

1910.28(b)(5)(i) |

Are elevated platforms equipped with 42” high guardrail on both sides? Or is there a 42″ barrier along the open sides of stairways and platforms that prevent falling? |

| 1910.29(k)(1)(ii) | Do guardrails include a 3.5” tall toeboard? |

| 1910.29(b)(2) | Are guardrails designed with a midrail midway between the top edge and the walking surface and / or vertical balusters or other members not more than 19 inches apart. |

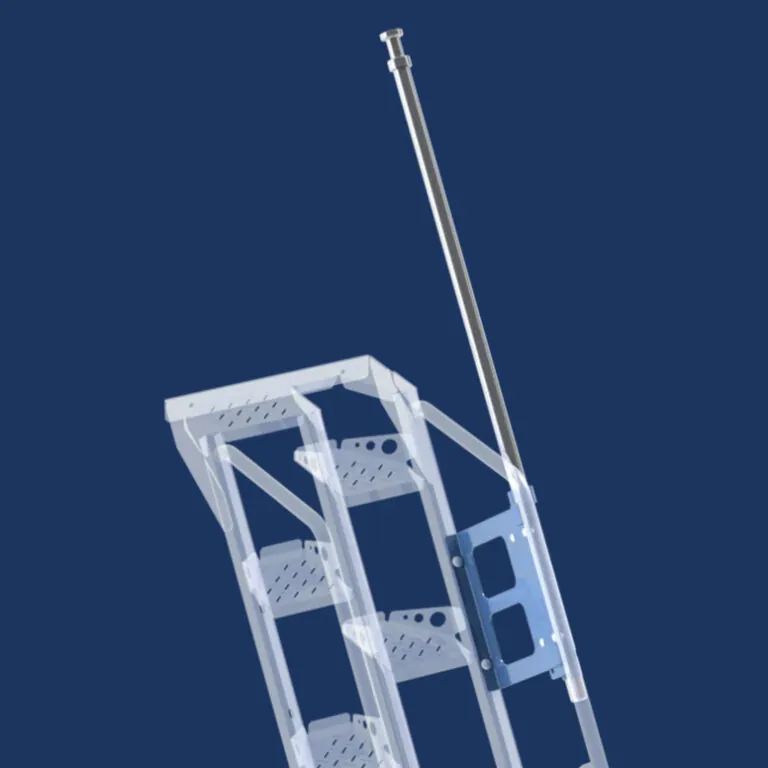

Fixed ladder checklist

| Section | Standard |

| 1910.28(b)(9)(i) | Are any fixed ladders extending higher than 24’ above a surface? If so, are they equipped with a personal fall arrest system or ladder safety system if installed after November 19, 2018. |

| 1910.25(b)(7) | Are NO fixed ladders being used to access operations that require routine and regular travel between levels, including access to operating platforms and equipment? |

| 1910.23(b)(1) | Are ladder rungs, steps, and cleats parallel, level, and uniformly spaced when the ladder is in position for use |

| 1910.23(b)(2) | Are fixed ladder rungs, steps, and cleats spaced not less than 10 inches (25 cm) and not more than 14 inches (36 cm) apart |

| 1910.23(b)(4) | Are rungs or cleats at least 16 inches wide? |

| 1910.23(d)(4) | Do the side rails and grab bars extend 42” above the top access level or landing platform? |

| 1910.23(d)(2) | Are fixed ladders positioned to provide 7” clearance from the centerline of grab bar / rung to the nearest permanent object? |

| 1910.23(d)(13)(i) | Do fixed ladders have minimum 15” clearance on either side of ladder to the nearest permanent object? |

| 1910.23(d)(13)(ii) | Is there a minimum 30 inches of distance from the centerline of the rungs to the nearest object on the climbing side of the ladder for adequate climbing / head clearance? |

| 1910.23(b)(6) | Are fixed metal ladders free of corrosion and protected from corrosion? |

| 1910.23(b)(8) | Are NO portable ladders being used as permanent access to elevated work surfaces? |

| 1910.23(b)(11) | Are employees facing the ladder when climbing? |

| 1910.23(b)(12) | Are employees using at least one hand to grasp the ladder (3-point contact) while climbing ladders? |

| 1910.28(b)(3)(iv) | Are fixed ladder holes protected by guardrail on all sides and a self-closing gate at the ladder entrance? |

Floor and wall opening checklist

| Section | What to check |

| 1910.28(b)(3)(i)

1910.28(b)(3)(ii) |

Are floor openings guarded by a cover, guardrail, or equivalent on all sides (except at stairways or ladder entrances)? |

| 1910.29(k)(1)(ii) | Are toeboards (minimum vertical 3.5” height) installed around the edges of permanent floor openings where persons may pass below the opening? |

| Are grates or similar type covers over floor openings such as floor drains designed to allow unimpeded foot traffic or rolling equipment? |

Loading dock checklist

| Section | What to check |

| 1910.28(b)(4)(ii)(A) | Are dock boards or bridge plates used transferring materials between docks and trucks? |

| 1910.28(b)(1)(i)

1910.28(b)(4)(i) |

If loading dock height is 48 inches or higher, is a guardrail system in place? |

| 1910.28(b)(4)(ii)(B) | Are employees engaged in material handling using motorized equipment at a dockboard not exposed to fall hazard greater than 10 feet? |

| 1910.22(a)(3) | Is the dock area maintained in a clean and dry condition free of hazards, spills or debris? |

OSHA walking working surfaces fact sheet

- Improperly maintained and used walking and working surfaces are the number 1 cause of slips, trips, and falls in the workplace.

- The OSHA walking working surface requirements are under section 1910 Subpart D.

- Section 1910 Subpart D covers ladders, stairways, manhole steps, dockboards, scaffolds, fall protection systems, and training requirements.

- OSHA 1910.22 defines the general requirements for walking and working surfaces.

- OSHA 1910.23 defines the requirements for ladders.

- OSHA 1910.25 defines the requirements for stairs.

- OSHA 1910.28 and 1910.29 define the duty to have fall protection and the requirements for fall protection systems.

- The OSHA catwalk standards for catwalk widths, toeboards, and load requirements are found in sections 1910.28 and 1910.29.

OSHA Grating Requirements

1. Surface conditions. The purpose of this section is to provide information to assist employers and employees to assure that walking and working surfaces are maintained free of hazards such as physical obstructions, debris, protruding nails or other fasteners or similar conditions, that could cause employees to slip, trip or fall.

Some hazards, such as snow, water, or ice, which by reason of recent weather or work operations may be present on workplace surfaces, present a slippery surface problem to employers. When these conditions cannot be eliminated completely, the employer can use alternatives such as slip-resistant footwear or handrails or stair rails to aid employees in maintaining their balance on the hazardous surfaces. Normally, slippery surfaces would occur only where snowfalls or freezing weather are of such frequency to make continued clearing or shoveling of workplace parking lots and sidewalks impractical, or where continuous use of water for washing down walking and working surfaces results in constantly slippery surfaces.

An effective housekeeping program may be used to minimize fall hazards where slippery surfaces are due to temporary or intermittent conditions. Absorbents can be used to clean up a spill where oily materials or corrosive liquids are accidentally spilled onto the floor.

2. Slip-resistance. A reasonable measure of slip-resistance is static coefficient of friction (COF). A COF of 0.5, which is based upon studies by the University of Michigan and reported in “Work Surface Friction: Definitions, Laboratory and Field Measurements, and a Comprehensive Bibliography,” is recommended as a guide to achieve proper slip-resistance. A COF of 0.5 is not intended to be an absolute standard value. A higher COF may be necessary for certain work tasks, such as carrying objects, pushing or pulling objects, or walking up or down ramps.

Slip-resistance can vary from surface to surface, or even on the same surface, depending upon surface conditions and employee footwear. Slip-resistant flooring material such as textured, serrated, or punched surfaces and steel grating may offer additional slip-resistance. These types of floor surfaces should be installed in work areas that are generally slippery because of wet, oily, or dirty operations. Slip-resistant type footwear may also be useful in reducing slipping hazards.

3. Mobile equipment. Mobile equipment operated in walkways or passageways creates a hazard to employees similar to any vehicular traffic. Appropriate warnings should be utilized to alert employees that mobile equipment is being used. Warning signs or mirrors can be used at intersections of walkways or passageways. Flashing lights or audible devices can be mounted on vehicles to warn employees of the presence of vehicles.

Adequate clearance must be provided to permit safe use of walkways, passageways, and aisles by employees when mobile equipment is parked in walkways, passageways, or aisles, and left unattended. Attended means that the operator is within 25 feet (7.5 m) of the vehicle and can see it [see § 1910.178(m)(5)(ii)]. Normally, adequate clearance can be considered as a one-way free passage of 18 inches (46 cm) or greater. However, consideration should be given to the number of employees using the passage; whether traffic will be in both directions; and whether the passageway is part of a means of emergency egress. (See subpart E — Means of Egress for specific requirements.)

4. Application of loads. Floor loading limitations would be of greatest concern to those employers engaged in the warehousing or storage of goods and materials. Surfaces that should receive special attention so as not to be overloaded include ramps, lifting platforms, dockboards, scaffolds and ladders.

It is important that employees involved in materials handling be made aware of the loading limitations of any surface upon which they may work or walk. Floor loading of a work surface will vary according to the nature of the work performed. For example, a work surface used as an office would not need the continued control of floor loading that would be necessary if the space was used as a warehouse.

5. Training. Employees who are expected to inspect, maintain, and/or repair surfaces must be trained in the skills needed to perform their duties. They should also be aware of the strength of the materials with which they are working, and the load bearing capabilities of the equipment or surfaces they are expected to maintain.

FAQs

What must be provided where doors or gates open directly onto a stairway?

OSHA requires that when a door or gate opens directly on a stairway, a platform is provided. The swing of the door or gate does not reduce the platform’s usable depth to less than 20 inches if installed before January 17,2017 and less than 22 inches if installed after January 17, 2017.

Which of the following are walking working surface hazards:

| Buckled mats | |

| Loose floor boards | |

| Leaking equipment | |

| Boxes or tools left in the walkway | |

| Dust on the floor from grinding or blasting operations | |

|

All of the above |