Understanding the IBC stair requirements and OSHA stair requirements for roof access, usability, and safety of each type of device will help you choose the right device for accessing roof hatches and unoccupied rooftop spaces. In certain circumstances, alternating tread stairs, ship stairs, and permanent ladders may be used to access unoccupied roofs through roof hatches.

OSHA & IBC Stair Requirements – Table of contents

- Occupied roofs vs unoccupied roofs

- Roof access applications

- Occupied roof egress requirements

- Unoccupied roof egress requirements

- IBC roof access requirements

- IBC roof access ladder requirements

- IBC roof access requirements for stairs

- IBC roof access hatch code requirements

- OSHA roof access requirements

- OSHA roof ladder access requirements

- OSHA roof stair requirements

- OSHA rooftop crossover stair requirements

- OSHA roof access hatch requirements

- Stair vs ladder for unoccupied roof access

IBC & OSHA Requirements for Occupied roofs vs unoccupied roofs

IBC differentiates between occupied and unoccupied roofs. The means of egress definition is the same for both, but the requirements are different since the two types of roofs have different uses and occupancy types.

Occupied roof definition

Since occupied roofs are accessible to building occupants, they must be provided by the same means of egress as any other occupied portion of the building. For occupied roofs, think of rooftop lounge areas, swimming pools or other roof assembly areas accessible to the general public. The occupied roof is considered a story within the building like any other enclosed story and the same means of egress requirements apply.

Unoccupied roof definition

Unoccupied roofs are accessible only to maintenance or construction workers. The workers might need to access the roof to service the roof itself or other mechanical equipment located on the roof.

Roof Access Applications

The next step is understanding the different roof applications. Common applications for roof access includes:

- Egress from or to occupied roofs

- Access to unoccupied roof areas

- Exterior access to rooftop equipment or roof elevation changes

OSHA Requirements for Occupied Foot Egress

Egress to occupied roofs must be through a stairway which meets all the requirements of IBC stairway design. Additionally, the stairway to a roof must be through a penthouse complying with IBC section 1510.2. With these requirements, stairway access to occupied roofs will typically be an extension of the exit stairways up to the roof.

IBC Requirements for Unoccupied Roof Egress

For unoccupied roofs, under the exception to IBC 1011.12, access to the roof from the top story is permitted to be by an alternating tread device, a ships ladder, or a permanent ladder.

Also, the exception to IBC 1011.12.2 allows access to unoccupied roofs to be a roof hatch or trap door. So for unoccupied roofs, a ladder or alternating tread stair extending through a roof hatch is the most common method of accessing the roof.

IBC Requirements for Roof Access

Roof access requirements are found in the 2018 IBC section 1011.12 Stairway to Roof:

In buildings of four or more stories above grade plane, one stairway shall extend to the roof surfaces unless the roof has a slope steeper than four units vertical in 12 units horizontal (33 percent slope)

Exception: Other than where required by Section 1011.12.1, in buildings without an occupied roof access to the roof from the top story shall be permitted to be by an alternating tread device, a ships ladder or a permanent ladder.

Section 1011.12.1 refers to Stairway to elevator equipment:

Roofs and penthouses containing elevator equipment that must be accessed for maintenance are required to be accessed by a stairway.

IBC Section 1011.12.2 Roof access:

When a stairway is provided to a roof, access to the roof shall be provided through a penthouse complying with Section 1510.2

Exception: In buildings without an occupied roof, access to the roof shall be permitted to be a roof hatch or trap door not less than 16 square feet in area and having a minimum dimension of 2 feet.

In summary, occupied roofs require access by a stairway, and unoccupied roofs can be accessed by an alternating tread stair, ships ladder or permanent ladder through a roof hatch. For unoccupied roof applications, alternating tread stairs are the safest and easiest to use solution because the user has a full tread depth to rest on each step. You can see the difference between an alternating tread stair and a ships ladder in this video.

IBC Requirements for roof access ladder

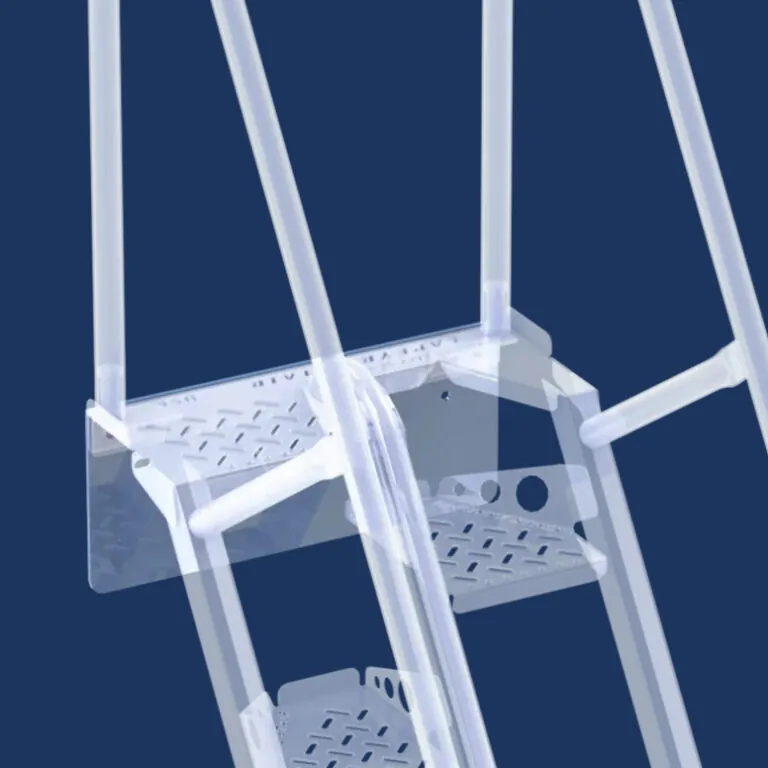

Ladders, ships ladders, and alternating tread stairs accessing unoccupied roofs must meet all the requirements for design per the relevant IBC section.

IBC 1011.16 Ladders defines the design requirements and use cases for ladders:

Permanent ladders shall not serve as part of the means of egress from occupied spaces within a building. Permanent ladders shall be constructed in accordance with Section 306.5 of the International Mechanical Code.

Permanent ladders can access certain unoccupied spaces including nonoccupied roofs that are not required to have a stairway.

IBC roof access code requirements for stairs

Stairways for roof access must meet all the requirements for design found in IBC 1011. For occupied roofs, stairways are required as a means of egress. For unoccupied roofs, alternating tread stair or ladders can be used in place of stairways.

IBC rooftop crossover stairs requirements

Typically rooftop crossover stairs are used for equipment or maintenance access and are not accessible by the general public. Rooftop crossovers would not need to comply with the IBC stairway design criteria because they are not used as a means of egress. Rooftop crossover stairs will need to comply with all OSHA and / or International Mechanical Code requirements.

IBC roof access hatch code requirements

The IBC roof hatch requirements are found under the exception to section 1011.12.2:

Exception: In buildings without an occupied roof, access to the roof shall be permitted to be a roof hatch or trap door not less than 16 square feet in area and having a minimum dimension of 2 feet.

Roof hatches accessed by alternating tread stairs or ships stairs must also be large enough to meet the IBC and OSHA head clearance requirements. The minimum head clearance is 80″ per IBC 1011.3. The opening size will depend on the angle of the stair.

For a 56 degree alternating tread stair, the minimum hatch size to meet the headroom clearance is 2’6″ x 6’0″.

For a 56 degree alternating tread stair, the minimum hatch size to meet the headroom clearance is 2’6″ x 6’0″.

For a 68 degree alternating tread stair, the minimum hatch size to meet the headroom clearance is 2’6″ x 4’6″.

OSHA Requirements for roof access

OSHA roof access requirements apply to all stairs and ladders used for equipment or maintenance access that are not used as a means of egress.

Access devices for these applications will fall under the International Mechanical Code rules for equipment on roofs or the OSHA design standards for

stairs and ladders. OSHA has many requirements for ladder and stair design but only two general requirements for how stairs and ladders should be applied in different situations. These are as follows:

- 1910.23(b)(8) Ladders are used only for the purposes for which they were designed;

- 1910.25(b)(8) Spiral, ship, or alternating tread-type stairs are used only when the employer can demonstrate that

it is not feasible to provide standard stairs.

OSHA leaves it up to the employer to ensure that the use of a stair or ladder device is safe and appropriate in each application, so employers must understand the safety, feasibility, and usability of stairs and ladders in different applications.

OSHA roof access ladder requirements

OSHA regulations for roof ladders are found in OSHA 1910.23 – Ladders.

Permanent roof ladders for regular maintenance use are defined by OSHA as fixed ladders:

- Fixed ladder means a ladder with rails or individual rungs that is permanently attached to a structure, building, or equipment. Fixed ladders include individual-rung ladders, but not ship stairs, step bolts, or manhole steps.

OSHA defines three different types of fixed ladders that may be used for permanent roof access:

- Side-step ladder means a type of fixed ladder that requires an employee to step sideways from it in order to reach a walking-working surface, such as a landing.

- Through ladder means a type of fixed ladder that allows the employee to step through the side rails at the top of the ladder to reach a walking-working surface, such as a landing.

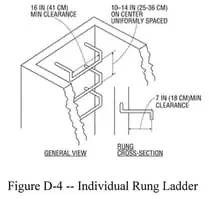

Individual-rung ladder means a ladder that has rungs individually attached to a building or structure.

Individual-rung ladder means a ladder that has rungs individually attached to a building or structure.

Employers must ensure that all ladders comply with the design requirements of section 1910.23(b), which includes design requirements for all ladder systems.

For permanent fixed roof ladders, employers must ensure that these ladders are also compliant with section 1910.23(d), which includes design requirements for all fixed ladder systems.

OSHA Roof ladder fall protection requirements

Employers must also ensure that fixed ladders for roof access are equipped with proper fall protection. Fall protection requirements are found in sections 1910.28.

1910.28(b)(1)(i) Except as provided elsewhere in this section, the employer must ensure that each employee on a walking-working surface with an unprotected side or edge that is 4 feet (1.2 m) or more above a lower level is protected from falling by one or more of the following:

- 1910.28(b)(1)(i)(A) Guardrail systems;

- 1910.28(b)(1)(i)(B) Safety net systems; or

- 1910.28(b)(1)(i)(C) Personal fall protection systems, such as personal fall

arrest, travel restraint, or positioning systems.

1910.28(b)(9)(i) For fixed ladders that extend more than 24 feet (7.3 m) above a lower level, the employer must ensure:

1910.28(b)(9)(i)(A) Existing fixed ladders. Each fixed ladder installed before November 19, 2018 is equipped with a personal fall arrest system, ladder safety system, cage, or well;

1910.28(b)(9)(i)(B) New fixed ladders. Each fixed ladder installed on and after November 19, 2018, is equipped with a personal fall arrest system or a ladder safety system;

1910.28(b)(9)(i)(C) Replacement. When a fixed ladder, cage, or well, or any portion of a section thereof, is replaced, a personal fall arrest system or ladder safety system is installed in at least that section of the fixed ladder, cage, or well where the replacement is located; and

1910.28(b)(9)(i)(D) Final deadline. On and after November 18, 2036, all fixed ladders are equipped with a personal fall arrest system or a ladder safety system.

OSHA roof access stair requirements

OSHA roof stairway requirements are found in OSHA 1910.25 – stairways. The regulations for roof stairs are no different than for any other OSHA stairs.

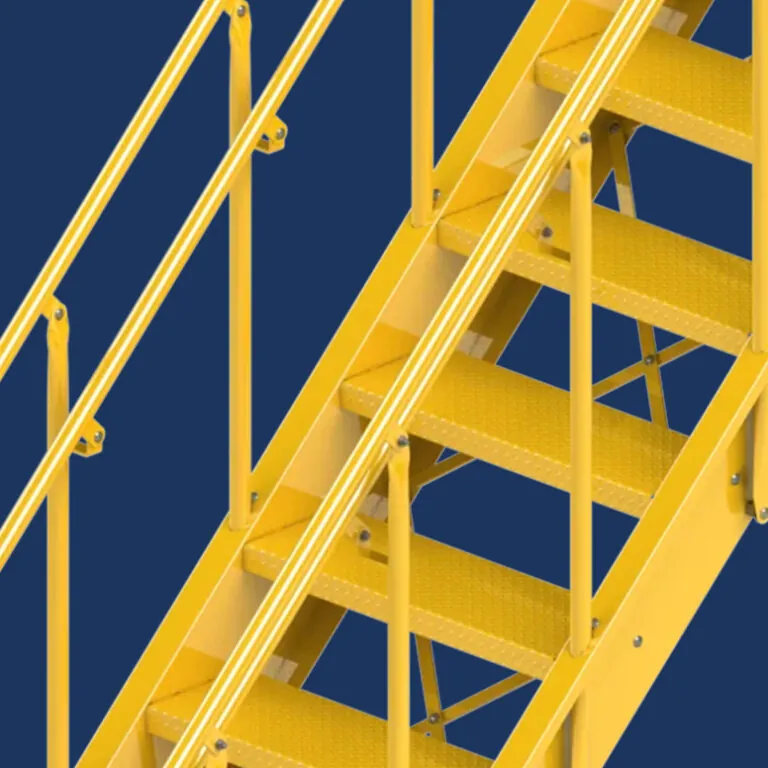

Typical OSHA roof access applications include accessing different elevations on a roof such as in this picture:

Roof equipment access is another common OSHA roof stair application.

OSHA rooftop crossover stair requirements

OSHA rooftop crossover stair requirements must comply with the same design requirements as all other OSHA stairs and platforms. For roof parapets or equipment crossovers, standard stair crossover systems may be used or if there is not room for a standard stair crossover, alternating tread stair crossovers can be used.

OSHA roof access hatch requirements

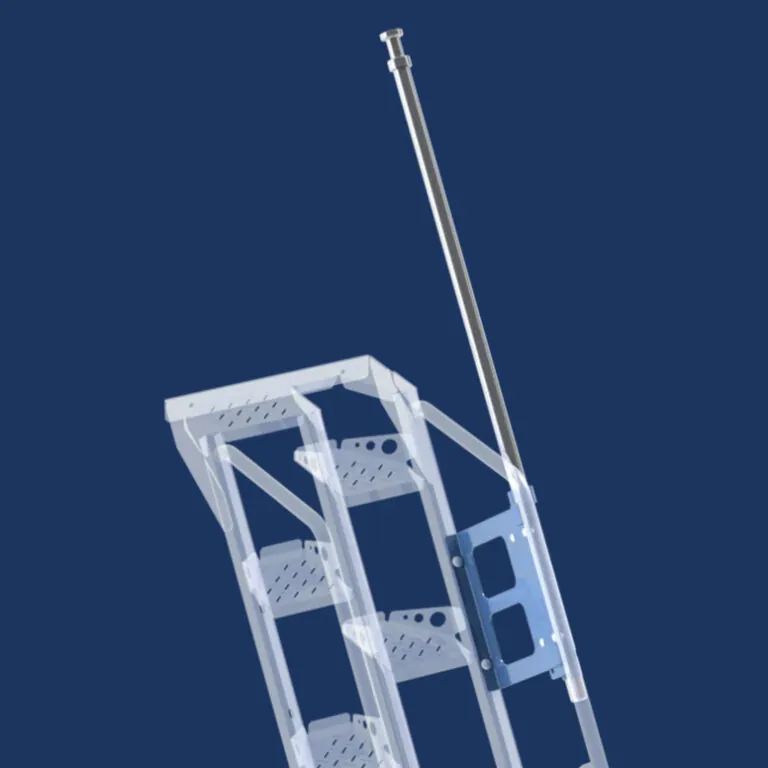

To meet the OSHA roof hatch standards, roof hatches should be designed to meet the minimum headroom clearances as defined in sections 1910.23 for ladders and 1910.25 for stairways.

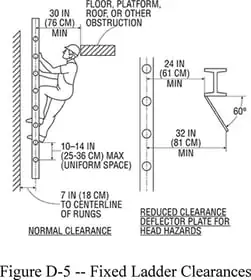

1910.23(d)(13)(ii) A minimum perpendicular distance of 30 inches (76 cm) from the centerline of the steps or rungs to the nearest object on the climbing side. When unavoidable obstructions are encountered, the minimum clearance at the obstruction may be reduced to 24 inches (61 cm), provided deflector plates are installed

Roof hatch opening must be large enough to account for the 30″ inch clearance from ladder rung to the roof obstruction or a deflector plate must be installed.

For stairways, section 1910.25(b)(2) states that Vertical clearance above any stair tread to any overhead obstruction is at least 6 feet, 8 inches (203 cm), as measured from the leading edge of the tread.

Roof hatches that are accessed by alternating tread stairs or ships ladders must be large enough to meet the headroom clearance requirements. The roof hatch opening size will depend on the angle of the stairway used to access the hatch.

For a 56 degree alternating tread stair, the minimum hatch size to meet the headroom clearance is 2’6″ x 6’0″.

For a 56 degree alternating tread stair, the minimum hatch size to meet the headroom clearance is 2’6″ x 6’0″.

For a 68 degree alternating tread stair, the minimum hatch size to meet the headroom clearance is 2’6″ x 4’6″.

Stair vs ladder for roof access

Should you choose a stairway or ladder for roof access?

For many years, fixed ladders have been the standard device for unoccupied roof access. But a study by the CDC estimates that approximately 20% of fall injuries involve falls from ladders and recommends several steps to preventing these falls including providing alternative, safer equipment for extended work at elevation.

OSHA also recognizes the danger of caged ladders. The 2017 Update to Walking-working Surface standards introduced the requirement for ladder safety systems to be used with all ladders that extend more than 24 feet above a lower level. Cages are no longer allowed as a ladder safety system.

For additional safety measures OSHA also requires that

1910.23(b)(11) Each employee faces the ladder when climbing up or down it;

1910.23(b)(12) Each employee uses at least one hand to grasp the ladder when climbing up and down it; and

1910.23(b)(13) No employee carries any object or load that could cause the employee to lose balance and fall while climbing up or down the ladder.

With these requirements, maintenance workers are forced to rope tools or other service equipment up and down rather than being able to carry them, making ladders very burdensome for workers.

In all cases, stairway systems are safer, more comfortable, and more efficient to use for workers than ladders.

Stairway systems can be used for all roof access applications:

- Roof hatch access

- Accessing a roof from the ground

- Accessing different elevations of a roof system

- Accessing equipment on rooftops

- Crossover stairs over a roof parapet

Conclusion

There are many different applications and code requirements for roof access. Understanding the difference between occupied roofs and unoccupied roofs can help you choose which type of device you need for roof access. Whenever possible choose a stairway as a safer alternative to ladders for roof access.

For unoccupied roof access through roof hatch or for space-confined rooftop equipment access stairs, alternating tread stairs are the safest, easiest to use solution.

FAQ

Is roof access required by code?

Roof access is required by the 2018 IBC building code for buildings of four or more stories. Occupied roofs require access by a stairway. Unoccupied roof access can be by an alternating tread device, a ships ladder or a permanent ladder.

What is an occupied roof?

An occupied roofs is a rooftop accessible to the general public for use as a lounge area, swimming pool or other general assembly area. The occupied roof is considered a story within the building and must be provided with a stairway as a means of egress.

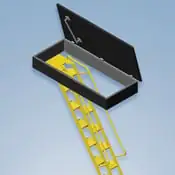

What is a roof hatch used for?

A roof hatch is used for safe access to an unoccupied rooftop in commercial buildings. The IBC building code permits roof hatches or trap doors to access unoccupied rooftop areas for service personnel to perform building and equipment maintenance.